When maintaining or repairing any mechanical tool, understanding the internal structure is crucial. This knowledge helps users identify issues, replace faulty elements, and ensure smooth operation. A clear visual representation of all components is often the best resource for tackling these tasks with confidence.

Having access to a detailed reference of each part in a chainsaw, from the smallest screws to the larger engine components, makes it easier to perform diagnostics and fix any malfunctions. Knowing where each piece fits and how it interacts with others is vital for both beginners and experienced repairers.

In this guide, we provide a comprehensive overview of how to navigate and utilize a detailed visual breakdown of your equipment. Understanding these elements can help extend the lifespan of your tool and make your maintenance process much more efficient.

Understanding the Stihl 08s Parts Diagram

When working with any mechanical tool, familiarity with its inner workings is essential. A detailed breakdown of all its components provides insight into how each part contributes to the overall functionality. This knowledge simplifies the repair and maintenance process, helping users easily identify damaged or worn-out elements that need attention.

How to Interpret the Visual Breakdown

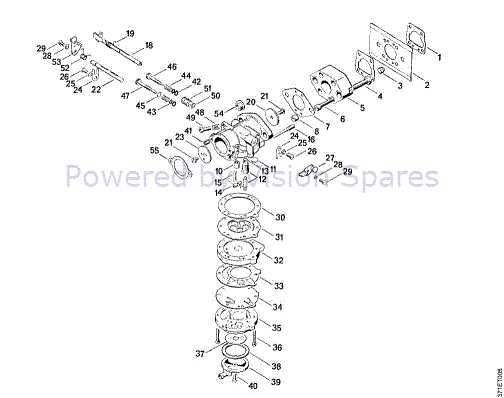

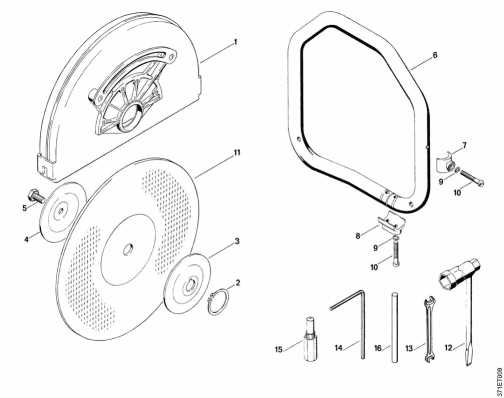

Visual guides that break down each part of a chainsaw are typically organized to show the layout and connections of every individual piece. Understanding these visual representations allows you to locate parts efficiently, making maintenance tasks quicker and less stressful. The key to interpreting these guides lies in recognizing the numbering and grouping of parts, which often follow logical steps from the assembly process.

Identifying Key Components for Maintenance

Some elements of your equipment require more attention than others. Regular inspection of certain critical components, such as the engine, fuel system, and cutting mechanism, is necessary to ensure proper functionality. A visual breakdown makes it easier to locate these essential parts and understand their role within the machine, ensuring that you’re focused on the right areas during maintenance and repairs.

How to Use the Stihl 08s Diagram PDF

Utilizing a comprehensive visual guide can greatly simplify the repair and maintenance process for your equipment. These detailed resources allow users to clearly see how each component fits together, making it easier to troubleshoot problems and carry out replacements. Knowing how to properly navigate these guides ensures that you can quickly identify the right parts and understand their specific functions.

To get the most out of a visual reference, start by familiarizing yourself with the layout. Most guides will present the components in a systematic order, often grouped by function or location within the machine. Pay attention to the numbering system, as it can help you trace the connections between parts. Additionally, make use of any labels or legends provided, as these often clarify the specific role of each item.

When you begin your repair or replacement tasks, refer back to the guide regularly. It’s also helpful to print the visual aid if possible, so you can mark parts that need attention or that have been replaced. This step-by-step approach ensures that you don’t miss anything and that you complete each task with confidence.

Essential Parts for Stihl 08s Maintenance

Effective maintenance of your equipment relies on regular attention to certain key components that ensure optimal performance. These critical elements require frequent checks and timely replacement to prevent breakdowns and extend the lifespan of your tool. Identifying and understanding these parts is essential for anyone looking to keep their machine running smoothly.

Engine and Fuel System

The engine is the heart of the machine, and ensuring its proper function is paramount. Regularly inspecting the fuel lines, filters, and spark plugs will help avoid issues such as starting failures or poor engine performance. Make sure to replace any worn-out or clogged filters and ensure fuel is flowing efficiently to keep the engine running at its best.

Cutting Mechanism and Blade Assembly

The cutting mechanism is one of the most important parts, as it directly impacts the efficiency and effectiveness of the tool. Pay close attention to the condition of the blade and any related components, such as the drive sprocket and chain. Regular sharpening and lubrication, along with timely replacement of damaged parts, will ensure a smooth cutting experience and reduce wear on the rest of the machine.