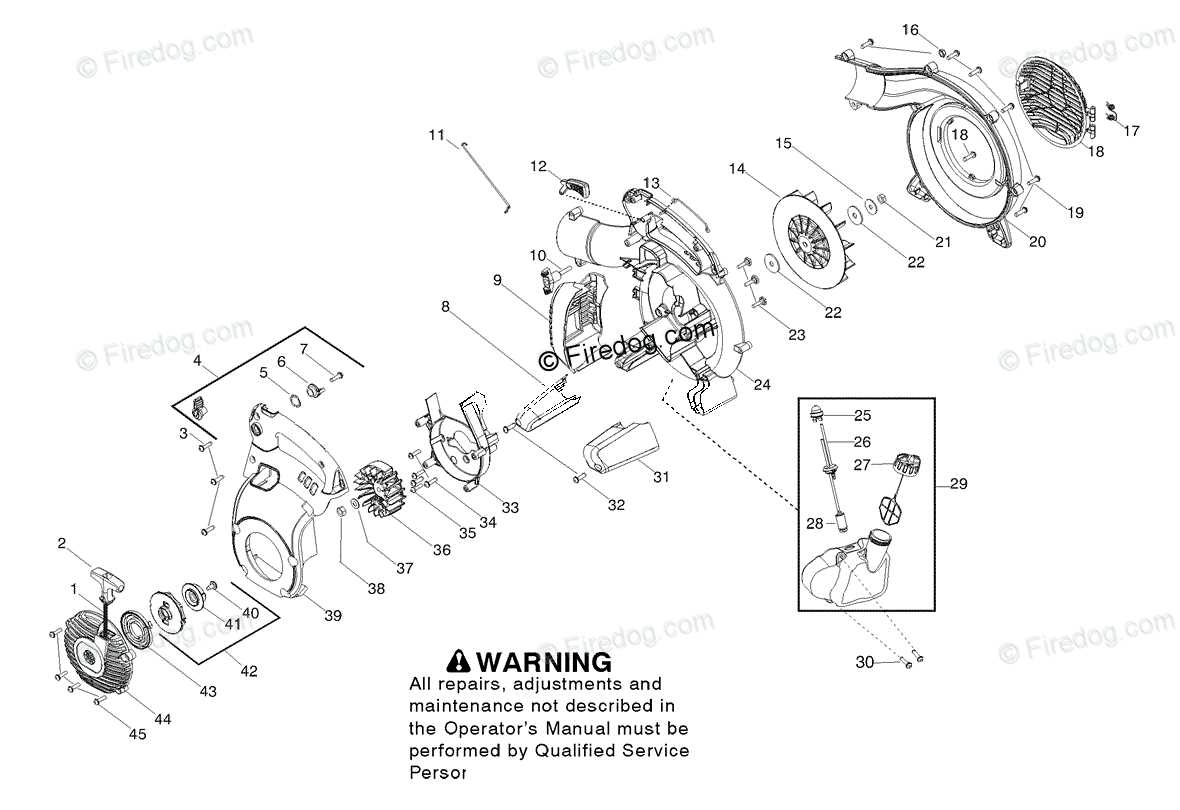

Maintaining and repairing outdoor equipment can seem challenging, especially when it comes to identifying the specific elements involved. A clear visual representation of all the crucial elements in your machine makes it much easier to diagnose issues, perform maintenance, or replace parts when necessary. Having a reference guide that maps out the assembly allows you to stay on track with repairs and ensures you are using the right parts for the job.

Knowing how to read these detailed guides and identify each component in your machinery will save you time and effort. Whether you’re troubleshooting a malfunction or planning preventative maintenance, a clear understanding of each part’s role is essential to effective repair. This type of visual aid can be invaluable for both beginners and seasoned technicians.

Equipped with a reliable reference, you can tackle repairs with confidence, ensuring that everything is in working order and your machine continues to function optimally for years to come.

Understanding the Husqvarna 125b Components

In any outdoor power equipment, a clear grasp of the individual elements that make up the machine is essential. Each component serves a specific function, and understanding how they all work together ensures smooth operation and proper maintenance. Recognizing the role of each part can help you troubleshoot issues, replace faulty components, and perform routine upkeep effectively.

Key Functional Elements

The key functional elements of your machine are designed to work together seamlessly. These components range from the engine to smaller, yet vital pieces like filters, air intakes, and exhaust systems. Each plays a crucial role in ensuring the machine runs smoothly. Understanding these systems helps you detect potential problems before they become serious issues.

Commonly Replaced Components

Some parts wear out over time and may require replacement to keep your equipment in peak condition. Items like spark plugs, fuel lines, and carburetors are often the first to experience wear due to regular use. Familiarizing yourself with the most commonly replaced elements allows you to perform maintenance proactively and avoid downtime.

How to Use the Parts Diagram Effectively

A visual guide can be one of the most valuable tools when performing maintenance or repairs on your equipment. It provides a detailed breakdown of each component, helping you understand their positioning and connection within the system. To use this guide effectively, it’s important to study the layout carefully and refer to it as needed throughout the repair or maintenance process.

Start by identifying the sections that are relevant to the issue you’re facing. Break down the equipment into manageable parts, focusing on one section at a time. The clarity of a well-drawn schematic allows you to pinpoint exact components, making it easier to order replacements or perform repairs without confusion. With practice, this tool becomes an essential part of your maintenance routine, offering both accuracy and efficiency during every task.

Common Repairs for Husqvarna 125b Parts

Over time, some components of your outdoor equipment may experience wear or damage, requiring repair or replacement. Understanding the most common repairs can help you proactively address issues and maintain optimal performance. Knowing which parts are likely to fail and how to fix them is essential to prolonging the life of your machine.

Frequent Issues and Fixes

Several common problems arise with regular use, and each can be fixed with the proper tools and knowledge. Here are a few of the most typical repairs:

- Fuel System Issues: Blocked or damaged fuel lines are a frequent problem. Ensure that fuel is flowing smoothly and replace any damaged lines.

- Ignition Problems: If your equipment fails to start, the spark plug may be worn out or clogged. Regularly inspect and clean or replace the spark plug as needed.

- Air Filter Maintenance: A dirty or clogged air filter can cause performance issues. Replace or clean the filter to maintain proper airflow.

Step-by-Step Repair Process

For each of these repairs, it is important to follow a systematic process:

- Identify the Issue: Use a schematic or guide to pinpoint the exact part or system that requires attention.

- Disassemble Carefully: Take apart the necessary components, keeping track of screws and small pieces.

- Replace or Repair the Faulty Part: Install the new part or fix the damaged element according to the manufacturer’s guidelines.

- Reassemble and Test: Put everything back together and run the machine to check that the repair was successful.