Maintaining heavy-duty vehicles requires a clear understanding of their internal systems and the individual elements that make them operate smoothly. For efficient repair and upkeep, having a detailed visual reference is essential. This guide aims to provide the necessary information to help you identify, troubleshoot, and replace various parts of your machine with confidence.

By familiarizing yourself with the layout and function of each component, you’ll be able to perform essential maintenance tasks with ease. Whether you are an experienced mechanic or a first-time user, this resource will empower you to extend the lifespan of your equipment and ensure it runs at optimal performance.

Proper knowledge of how each section fits together is critical, especially when dealing with mechanical failures or seeking upgrades. This guide will support you in achieving better efficiency and avoiding costly repairs in the future.

Understanding Bobcat 2200 Parts

In any machine, each individual element plays a crucial role in its overall performance and efficiency. Understanding the structure and function of every component is essential for anyone involved in its maintenance or repair. Knowing where each part fits and how it interacts with others ensures that you can diagnose issues accurately and keep the system functioning smoothly.

Each section of your vehicle is designed to handle specific tasks, from propulsion and steering to electrical functions and hydraulic power. Familiarizing yourself with the layout and purpose of these elements not only helps in troubleshooting but also enables you to make informed decisions when replacements or upgrades are needed.

By studying the layout of various systems, you can gain insight into how the machine operates as a whole. Whether you are addressing a minor malfunction or performing routine maintenance, understanding the relationship between the key components will enhance your ability to make effective repairs and improve overall vehicle longevity.

How to Use the Bobcat 2200 Diagram

To effectively repair or maintain any heavy equipment, it is essential to have a clear and accurate visual reference. These guides help you identify the various elements of the machine and understand their specific functions within the system. By using a diagram, you gain a visual understanding of how everything fits together, making it easier to diagnose problems and carry out repairs.

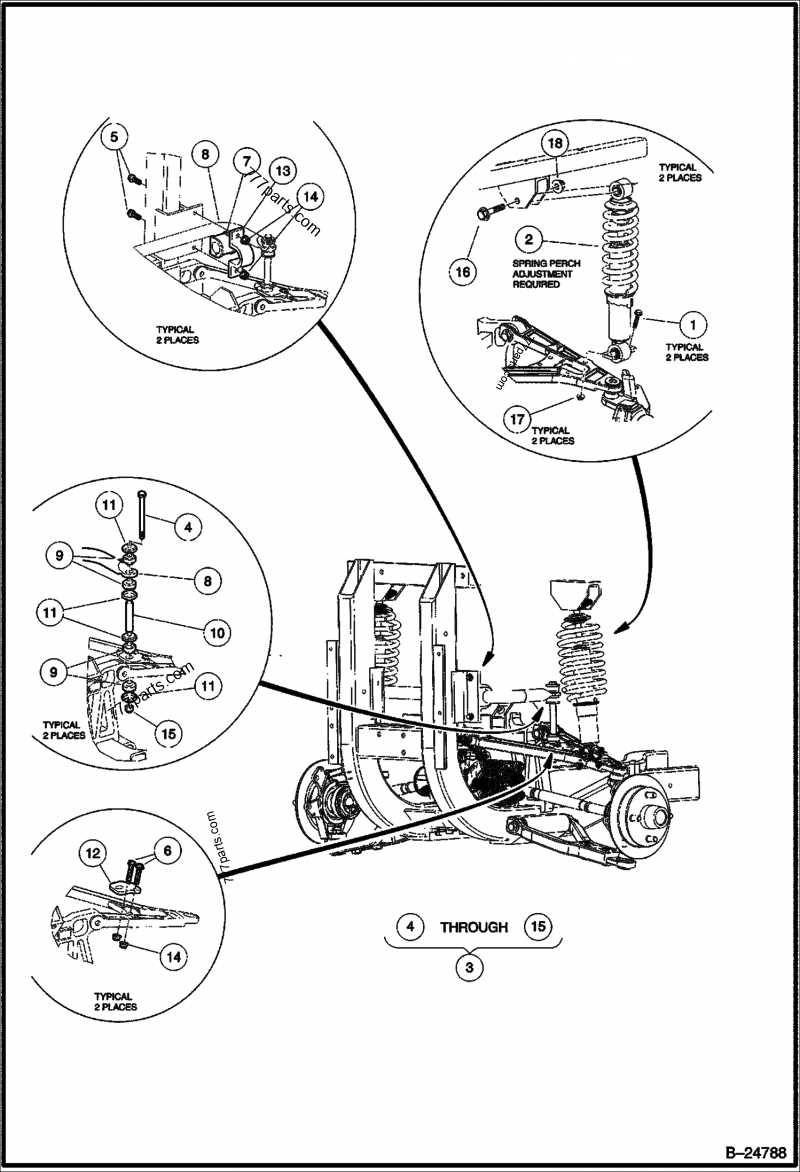

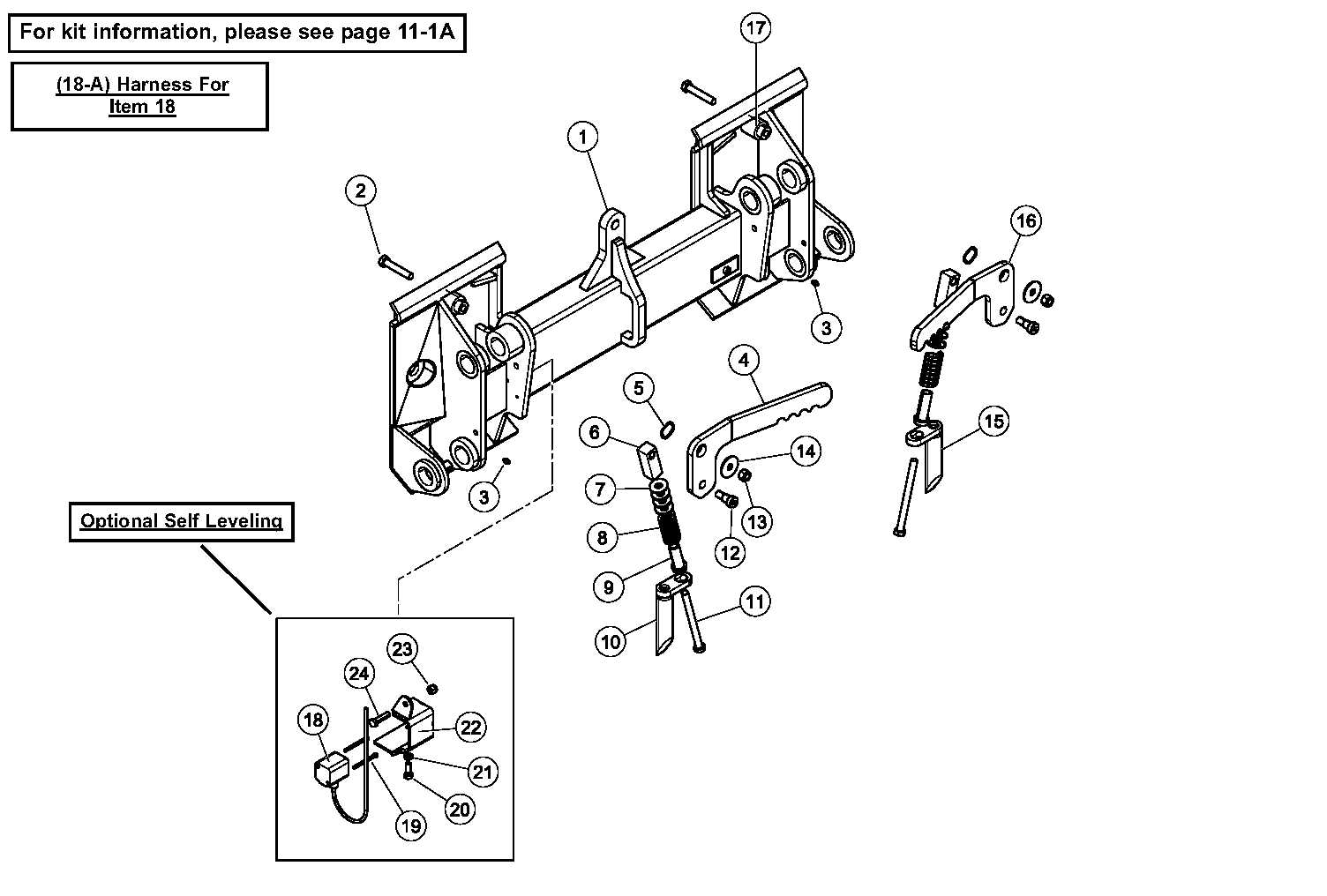

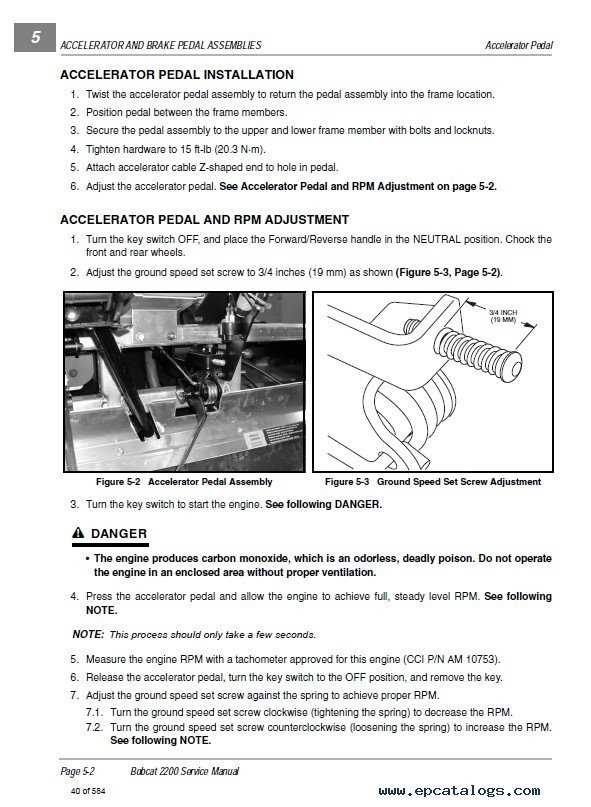

Identifying Components

The first step in using the schematic is learning how to identify each individual part. Look for labeled sections or numbers that correspond to specific elements. This can help you quickly locate the part you need to work on, whether you’re troubleshooting a malfunction or conducting routine maintenance.

Following the Flow of Systems

A good visual guide will not only show where the components are located but also how they work together. Pay attention to the connections between different parts, such as electrical wires or hydraulic lines. Understanding these relationships is vital for diagnosing issues and ensuring that all systems are working as intended.

Effective use of these visual references will reduce time spent searching for specific parts and simplify the overall repair process. Whether you’re performing minor repairs or major overhauls, having a detailed schematic on hand is an invaluable tool for anyone working on the machine.

Common Repairs for Bobcat 2200 Components

Over time, various elements of your machine may experience wear or damage due to heavy use or environmental factors. Understanding the most common issues that arise can help you prepare for repairs and ensure that you address problems quickly before they worsen. Regular maintenance and early intervention are key to keeping the vehicle running efficiently.

Among the most frequent repairs are issues with the hydraulic system, such as leaks or pressure drops, which can significantly impact performance. Electrical problems are also common, particularly with the wiring and connectors that manage the vehicle’s power and control systems. These components often need to be inspected, cleaned, or replaced to ensure proper functionality.

Another common repair involves the drivetrain, including belts, pulleys, and gears. Regular wear on these parts can lead to reduced efficiency or even mechanical failure. Replacing worn parts and ensuring proper alignment will help maintain smooth operation and prevent more serious damage.

By staying proactive and addressing these common issues early on, you can avoid costly repairs and downtime, extending the lifespan of your equipment and ensuring optimal performance.