When working with agricultural machinery, it’s essential to understand how the various elements of the attachment system function together. These components play a crucial role in the tractor’s ability to connect and operate a range of implements, ensuring maximum efficiency during tasks like plowing, tilling, and lifting.

Each part in the assembly has a specific purpose, and knowing their relationships is key to proper maintenance and troubleshooting. Whether you are a professional or a hobbyist, familiarity with these elements can help optimize your equipment’s performance and reduce downtime.

Identifying the individual pieces of this system can be a challenging task without a clear guide. However, understanding their layout and interconnections makes it easier to spot issues and perform necessary repairs or adjustments. Proper knowledge of the components ensures smooth operation and longevity of the machine’s working parts.

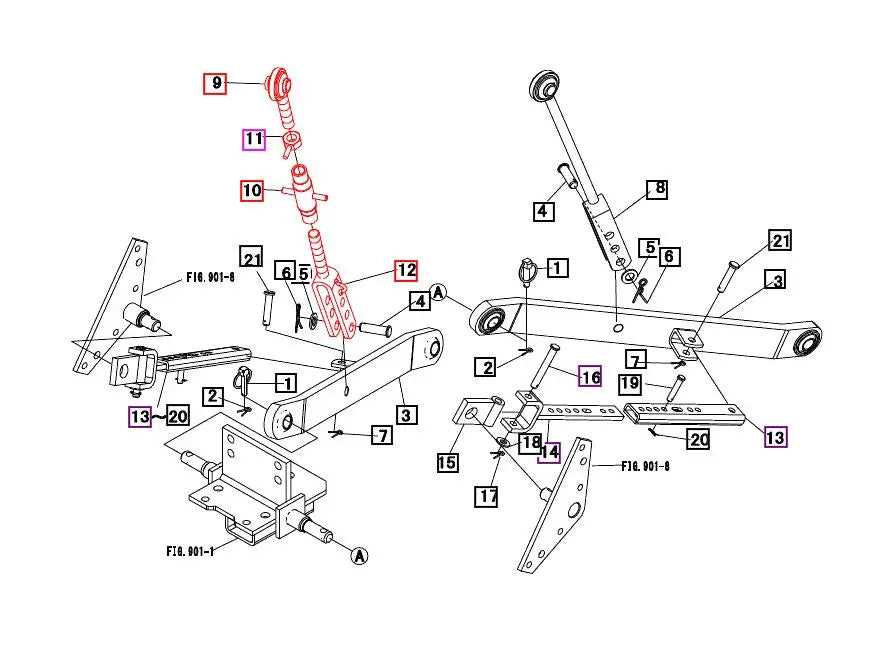

Understanding the 3 Point Attachment System

The attachment system in agricultural machinery is designed to connect the tractor with a variety of implements. This system enables the equipment to perform essential tasks such as plowing, lifting, and tilling with efficiency. Its design allows for secure and adjustable connections, providing flexibility to the operator.

Key Features of the System

The main feature of this assembly is its ability to adjust the height and angle of attached implements. This flexibility allows for precise control over the work being done, whether it’s adjusting depth for soil preparation or lifting implements for transport. Sturdy construction ensures durability even under heavy use, making this system a reliable choice for demanding agricultural tasks.

Importance of Proper Functioning

When this connection system malfunctions, it can lead to issues such as poor implement control or reduced functionality. Regular maintenance is vital to ensure smooth operation, as small adjustments or repairs can prevent costly damage to both the tractor and the implements. Keeping the system in good working order ensures the tractor performs optimally over time.

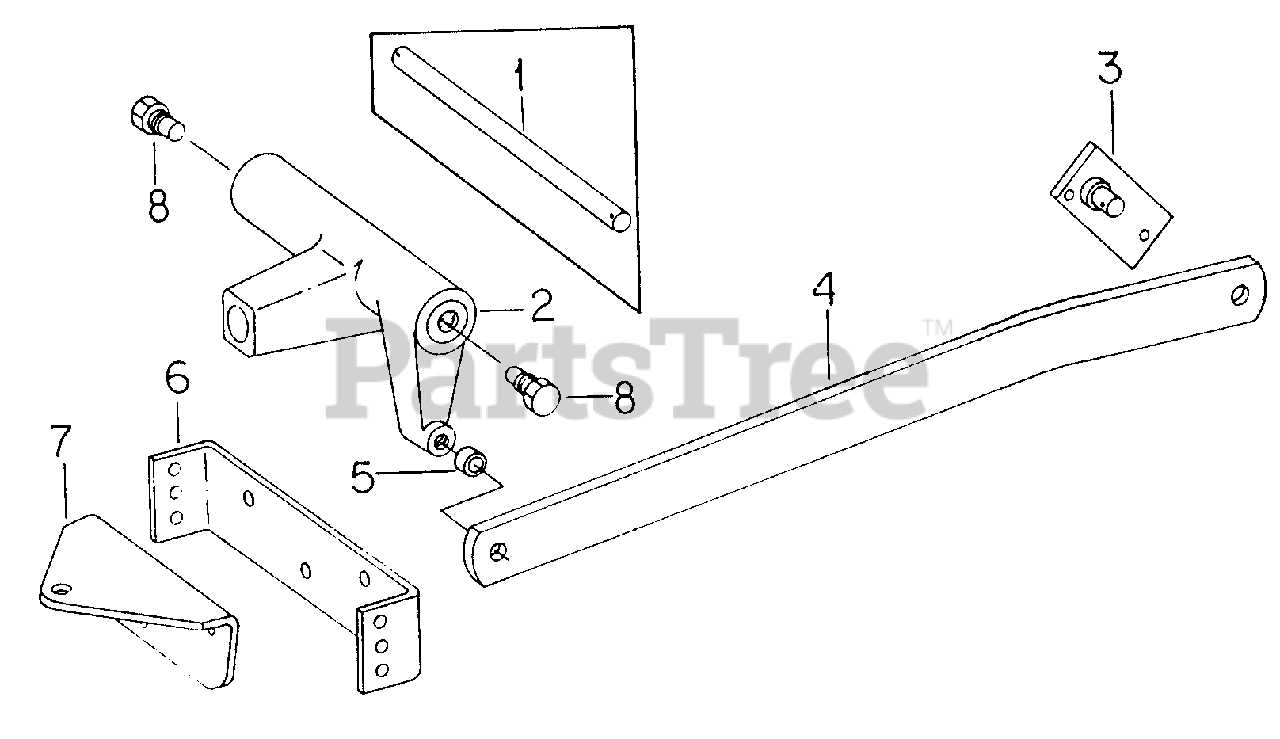

Key Components of the Attachment Assembly

The system that connects agricultural implements to the tractor is made up of several key components. These elements work together to ensure stability, flexibility, and functionality, allowing the machine to perform a variety of tasks efficiently. Each piece plays a distinct role in supporting and controlling the connected equipment, providing essential features for proper operation.

Major Structural Elements

One of the main components in this system is the frame, which supports the entire assembly and provides the foundation for attachment. The frame is typically designed to be both strong and adjustable to accommodate different types of implements. Proper alignment of the frame is essential for the effective use of the machinery.

Adjustment Mechanisms

Another crucial part of the system is the mechanism that allows for the adjustment of implement height and angle. These adjustment points are vital for precision work, enabling the operator to modify the setup according to the specific needs of the task at hand. Regular inspection of these components ensures they function smoothly, preventing wear and tear that could lead to malfunction.

How to Maintain and Repair the Attachment System

Proper maintenance and repair of the attachment system are crucial for keeping the tractor and connected implements working efficiently. Regular attention to this area ensures that the components remain in optimal condition, preventing costly repairs and downtime. The goal is to identify and address issues early to maintain smooth operation throughout the year.

Routine Maintenance Practices

Routine maintenance includes lubricating moving parts to reduce friction and wear. It’s important to check the adjustment mechanisms regularly for proper function, ensuring they are not too tight or too loose. Cleaning these parts helps prevent debris from interfering with their performance, while also prolonging the life of the equipment.

Identifying and Fixing Common Issues

Common issues include wear on pins and bushings, rust accumulation, or damage to the frame. When problems arise, it’s essential to replace worn or broken components promptly to avoid further damage. Proper tools and techniques, such as using the right torque for bolts, can ensure that the system is restored to full working order without complications.