When it comes to maintaining your lawn equipment, it’s crucial to familiarize yourself with its core elements. Knowing the different components and how they work together can significantly enhance the longevity and performance of the machine. Each part plays a unique role, ensuring that the machine operates smoothly and efficiently throughout the seasons.

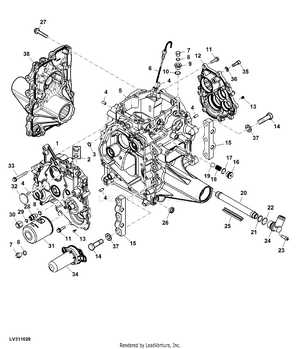

Proper identification and understanding of these elements allow for quicker troubleshooting and more effective repairs. Whether you’re looking to replace a worn-out component or simply perform routine maintenance, having a visual reference and knowledge of each section can save time and effort.

As you explore the individual parts and their connections, you’ll gain valuable insight into how they function together. This understanding not only empowers you to take better care of your equipment but also ensures it remains in top working condition for years to come.

Understanding the Lawn Tractor’s Essential Mechanism

In any gardening or landscaping machine, the working mechanism responsible for cutting and shaping the terrain is essential for achieving optimal performance. Understanding how the various components interact allows for better maintenance and the smooth operation of the equipment. These parts are designed to work in harmony, each fulfilling a specific role that contributes to the overall efficiency of the device.

The Role of Cutting Mechanism

The cutting mechanism plays a crucial role in ensuring the machine delivers precise and even cuts. This system typically includes blades and rotating components that work together to slice through grass and other materials effectively. Understanding how these parts are arranged and how they function will help you troubleshoot issues and make informed decisions during maintenance or replacement.

Maintaining the Functionality of the System

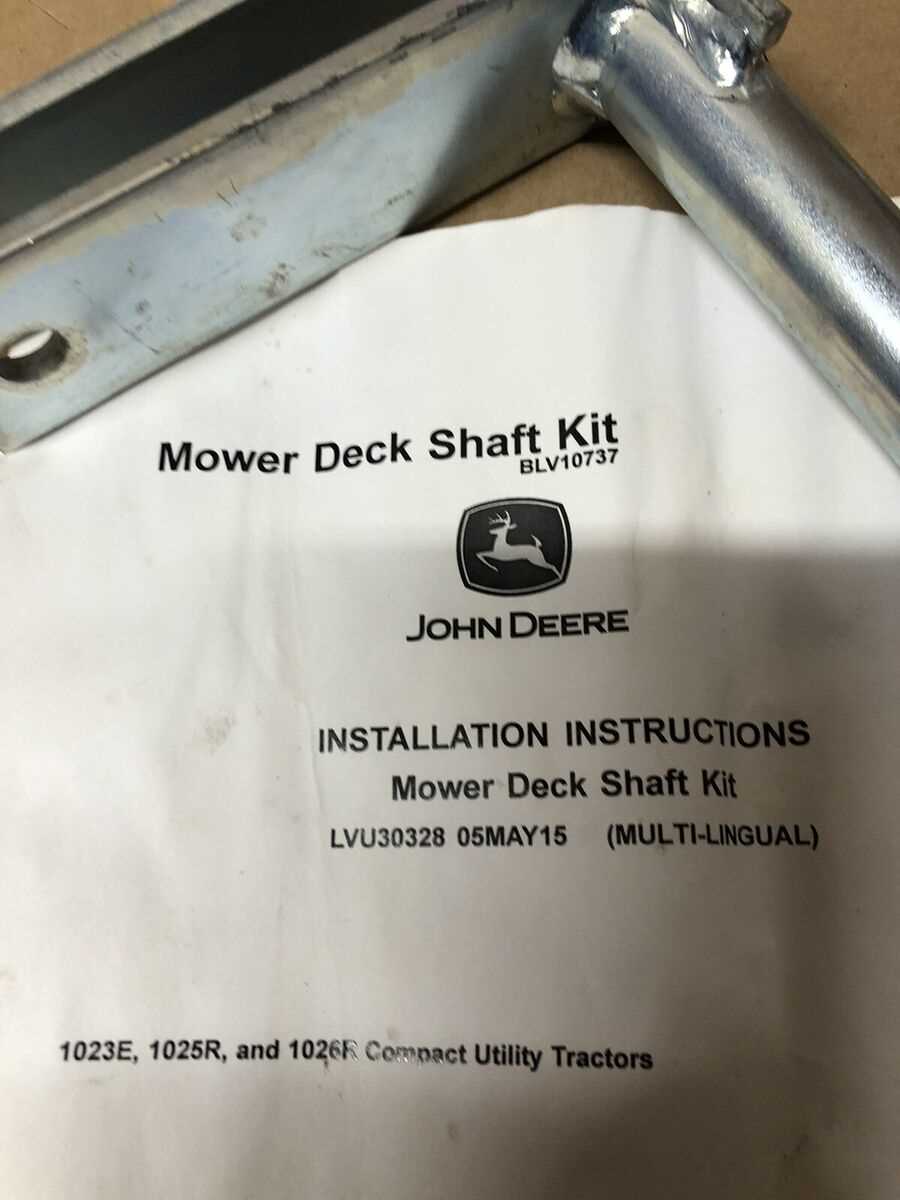

Regular upkeep is vital to keeping the cutting system functioning at its best. By regularly inspecting and maintaining key parts such as the rotating elements, bearings, and connectors, you can prevent unnecessary wear and avoid costly repairs. Proper care ensures that each component continues to operate smoothly and that the machine remains reliable throughout its service life.

Key Components of the 60-Inch Cutting System

Understanding the essential elements of a lawn care machine is critical for ensuring proper function and efficiency. Each part is designed to fulfill a specific role, working together to achieve smooth operation. Knowing these components helps in troubleshooting issues, replacing worn-out parts, and conducting regular maintenance to keep the system running smoothly.

Rotating Blades and Their Function

The rotating blades are central to the system’s operation. They are responsible for cutting grass and other vegetation as the machine moves across the terrain. These blades are mounted on a spindle and are designed to rotate at high speeds, ensuring a clean and even cut. Proper maintenance of the blades ensures their longevity and efficient performance.

Supporting Bearings and Connections

Bearings and other connecting elements are vital for the smooth rotation of the cutting components. These parts help reduce friction, allowing the blades and other moving elements to work seamlessly together. Regular inspection and lubrication of these components can prevent unnecessary wear and ensure the overall system operates at peak performance.

How to Maintain the Cutting System Components

Proper maintenance of the essential components in your lawn care machine ensures its optimal performance and longevity. Regular upkeep prevents wear and tear, reduces the risk of malfunction, and ensures a clean and efficient operation. By following the right steps, you can easily extend the lifespan of the equipment and avoid costly repairs.

- Inspecting Blades Regularly: Examine the blades for signs of damage, wear, or dullness. Replace or sharpen them as necessary to maintain cutting quality.

- Lubricating Moving Parts: Apply lubricant to bearings, spindles, and other moving components to reduce friction and prevent rusting. This ensures smooth operation.

- Cleaning After Use: After each use, remove grass clippings and debris from the system. This prevents build-up that can lead to rust and reduced efficiency.

Steps for Proper Inspection and Maintenance

- First, check the integrity of the rotating components for cracks or bends that could affect performance.

- Next, ensure all bolts and fasteners are securely tightened to avoid any parts loosening during use.

- Finally, test the system by running it briefly to listen for any unusual noises, which may indicate the need for further maintenance.