Proper maintenance of your snow removal equipment ensures it operates smoothly and efficiently throughout the winter months. Knowing the different parts and their functions is essential for any user looking to perform repairs or upgrades. Familiarity with the system layout allows for quick troubleshooting and effective handling of malfunctions.

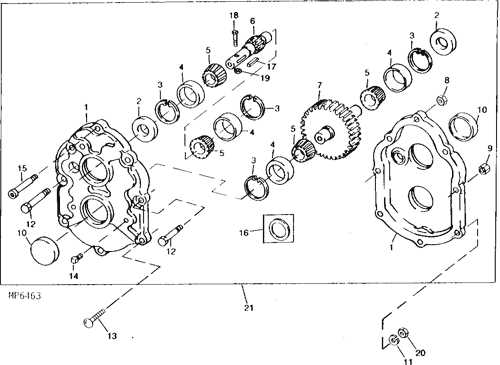

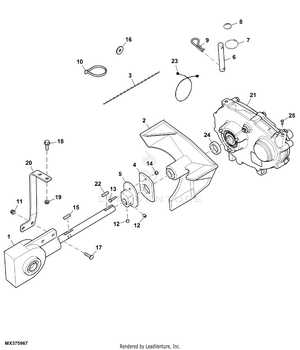

Visual aids like detailed system layouts are crucial tools for identifying each component. These illustrations provide a clear overview of how all parts work together, simplifying the repair process and helping users understand the inner workings of the machinery. Whether you are replacing worn-out components or performing routine checks, having a comprehensive guide can save time and effort.

Understanding the structure of your equipment helps you stay ahead of potential issues, prolonging the life of the machine. In this article, we will break down the essential elements involved in maintaining and repairing your unit, with a focus on effective solutions and helpful insights.

Understanding Snow Removal Equipment Components

Every piece of equipment designed for clearing snow consists of multiple interconnected elements, each playing a vital role in ensuring optimal performance. By becoming familiar with these components, operators can efficiently troubleshoot issues and conduct necessary repairs. The overall functionality of the machine relies on the seamless cooperation of these parts, making it crucial to understand their purpose and positioning.

Key Functional Elements

At the core of the machine, the engine and transmission drive the movement, allowing the clearing mechanism to function. Additionally, the auger and impeller work together to break down and expel snow. Understanding the placement and interaction of these parts is important for identifying areas that may require maintenance. Regular inspection of wear-prone components ensures the system remains functional throughout the season.

Maintenance and Replacement Tips

Routine checks of critical components such as belts, bearings, and blades can prevent unexpected failures. Wear on these elements is common over time, and early detection can help avoid costly repairs. In cases of severe damage, replacement is often the best option to restore functionality. Familiarity with the layout of the system simplifies the replacement process and guarantees better results.

Prolonging the lifespan of the equipment requires a proactive approach. Ensuring all components are correctly lubricated, properly aligned, and free of debris will minimize the risk of mechanical failure. Regular attention to these details not only enhances the performance but also extends the overall life of the machine.

How to Read a Snow Removal Equipment Layout

Understanding how to interpret the layout of your snow removal machinery is essential for troubleshooting, repairs, and part replacement. A well-designed schematic offers a clear view of the equipment’s components, their positions, and how they interact. By mastering the symbols, labels, and connections, you can efficiently identify the necessary parts and take the right action when something goes wrong.

Each component in the schematic is typically represented by a specific symbol or label, often accompanied by a part number for easy identification. These illustrations are organized to show the machinery in a disassembled view, with each element clearly marked. It’s important to familiarize yourself with the conventions used, such as lines connecting parts to indicate movement or interaction, and shaded areas that may indicate areas under stress or wear.

Once you are comfortable with the layout, the next step is to correlate the visual representation with the actual components on your machine. By matching the parts in the diagram with those on your equipment, you’ll be able to spot any discrepancies, assess potential issues, and proceed with the appropriate repairs or replacements.

Common Repairs for Snow Removal Equipment

Over time, regular use of snow clearing machinery can lead to wear and tear on its key components. Identifying and addressing these issues early can prevent more significant problems down the line. Common repairs typically involve parts that experience heavy friction, stress, or exposure to the elements. By understanding which areas are most vulnerable, operators can perform necessary fixes to keep the equipment running smoothly.

Worn Belts and Cables

One of the most frequent repairs involves replacing worn belts and cables. These components are under constant tension and can stretch, crack, or snap with prolonged use. If the equipment begins to lose power or functionality, it may be due to a faulty belt or cable. Regular inspection and replacement of these parts will ensure proper operation and avoid more extensive damage.

Auger and Impeller Maintenance

The auger and impeller play crucial roles in breaking down and expelling snow. Over time, these parts can become clogged with debris or suffer from wear, reducing their efficiency. Cleaning and sharpening the auger blades regularly is essential to maintain optimal performance. In some cases, replacing damaged or rusted components may be necessary to ensure the system operates at full capacity.

In addition, checking for misalignment or damaged bearings that support moving parts will help prevent further complications. Regular upkeep of these critical areas not only enhances the equipment’s longevity but also improves its ability to clear snow effectively during winter storms.