When it comes to keeping your cleaning equipment in top condition, understanding its internal structure is crucial. Knowing how different elements interact and how to replace or maintain them can save you time and money on repairs. A clear breakdown of these parts is essential for efficient troubleshooting and upkeep.

In this guide, we’ll explore the various components that make up a vacuum cleaner, providing you with detailed insights into each one. Whether you’re looking to fix a malfunction or simply learn more about how the machine works, identifying and understanding these elements will help you ensure proper performance.

Efficient repairs begin with the right knowledge, and the more you understand the inner workings of your device, the easier it will be to maintain its longevity. Let’s dive into the main features that need attention for smooth operation and longevity.

Understanding Key Components

Every cleaning device is made up of several vital elements that work together to ensure smooth operation. Understanding these components is essential for proper maintenance and troubleshooting. Whether it’s the motor, suction system, or brushes, each part plays a unique role in achieving optimal performance. By familiarizing yourself with how these elements function and interact, you can ensure your equipment continues to run efficiently.

The Motor and Power System

The motor is the heart of any cleaning unit, driving the suction mechanism and other key functions. A well-maintained motor ensures consistent power output and suction strength. Knowing how to care for and replace this component can prevent many common issues such as loss of suction or overheating. Additionally, the power system, including cords and switches, allows users to operate the device smoothly, making it crucial to ensure these are in good condition.

The Suction and Brush Mechanism

The suction system works in tandem with the brush mechanism to lift dirt and debris from various surfaces. The brushes, whether rotating or stationary, are designed to agitate debris, helping the suction system collect it more effectively. Over time, both these components can wear out, reducing the efficiency of your cleaner. Regular cleaning and maintenance of these systems ensure maximum performance and longevity of your equipment.

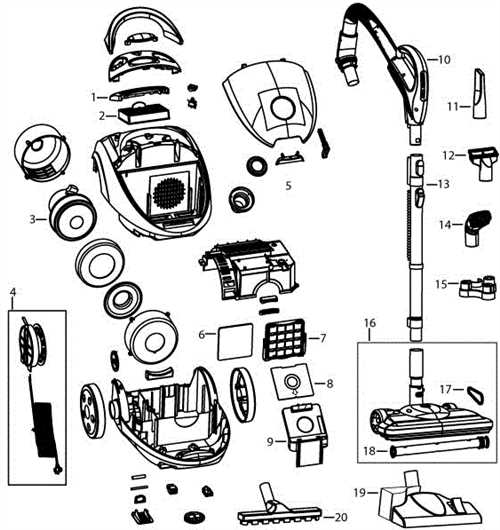

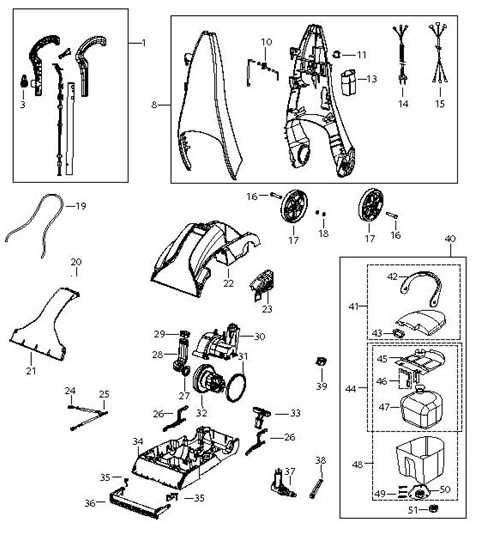

Identifying Key Components in the Breakdown

Understanding the essential components of your cleaning device is key to efficient operation and troubleshooting. Recognizing how each part fits into the overall system can help you identify issues quickly and make necessary repairs or replacements. Visual aids, such as component breakdowns, offer a clear representation of the layout and function of each element, providing a helpful guide for both maintenance and repair tasks.

Main Assembly and Housing

The main assembly, often including the housing, is the structure that holds all other components in place. It serves as the foundation, providing support for critical elements like the motor, brushes, and suction system. By examining this part, you can get a better understanding of how the internal systems are positioned and connected. Proper care of the housing ensures that all parts remain aligned and functioning properly.

Suction Path and Filter System

One of the most important systems in any cleaner is the suction path, which includes air ducts, filters, and the dust collection chamber. This path directs airflow and captures debris, ensuring optimal cleaning performance. By identifying the parts within this system, such as the filter and suction inlet, you can better understand how to maintain or replace them when they become clogged or damaged. Regular inspection of these parts can greatly improve the machine’s efficiency.

How to Replace Key Components Easily

Replacing malfunctioning or worn-out components of your cleaning device doesn’t have to be complicated. With the right tools and knowledge, many of these repairs can be done quickly and effectively. Understanding the basic steps for replacing common parts can save you both time and money. This guide will walk you through the process, making it simple to keep your equipment running smoothly.

Step-by-Step Guide for Replacements

Start by ensuring that the device is unplugged and safely disassembled. Focus on removing only the parts that need replacement, avoiding any unnecessary disassembly. For example, when replacing a brush or filter, carefully detach the worn component and replace it with a new one. Make sure each piece is securely fastened and reassemble the device in the reverse order. Double-check for proper fitment to ensure everything is aligned and functioning properly.

Tips for Successful Repairs

Before you begin, always consult the user manual or any available instructional guides specific to your device. This can provide insights into which components are easiest to replace and which might require professional assistance. Additionally, keep a set of essential tools on hand, such as screwdrivers, pliers, and any other specialty items needed for the repair. Regular maintenance and timely replacements will keep your equipment in optimal working condition.