Every mechanical system relies on well-designed components working in unison to achieve optimal performance. The efficiency of these systems often depends on the precise interaction of various elements, each playing a vital role. Recognizing how each piece contributes can enhance maintenance and improve overall functionality.

In this guide, we will explore the essential components of a specific pumping system. By breaking down its key elements, we aim to provide a clear understanding of their structure and operation. This knowledge is crucial for anyone involved in maintaining or troubleshooting such systems.

Mastering the details of each part allows for better decision-making when it comes to repairs, upgrades, or replacements. Proper comprehension ensures smoother operation and extends the lifespan of the equipment. Through this detailed overview, we will highlight how the parts interact and why their proper functioning is so important.

Understanding Aaa 8.7ga12 Pump Components

In any mechanical system, the individual elements must work seamlessly to ensure efficiency and longevity. The key to a successful operation lies in the understanding of how these components function together. Identifying and recognizing each part’s role in the overall system can greatly improve troubleshooting and maintenance efforts.

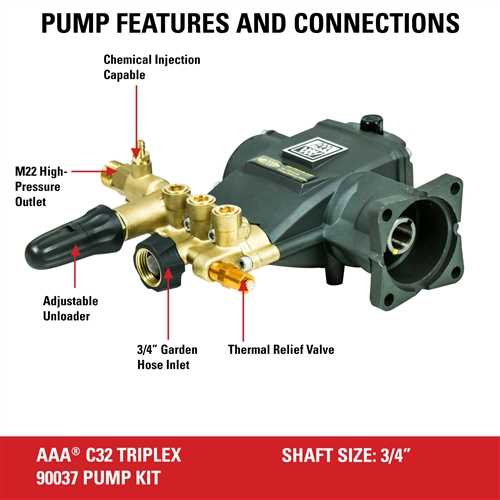

Key Elements of the System

The system consists of various integral components that contribute to its functionality. From the central mechanism to auxiliary elements, each piece serves a specific purpose. These elements interact with one another in a precise sequence, ensuring smooth operation and minimizing the risk of failure. For example, certain components are responsible for controlling flow, while others manage pressure or direct energy to necessary areas.

Maintenance and Repair Considerations

Understanding the role of each element is crucial for effective maintenance and repair. Regular inspections can prevent unexpected breakdowns and ensure the system runs efficiently. Replacing worn-out parts or recalibrating components at the right time can extend the equipment’s lifespan and enhance its performance. In some cases, a minor issue with one component can disrupt the entire system, making proper attention and care essential for reliable function.

Detailed Breakdown of Pump Part Functions

Understanding how each element of a mechanical system operates is essential for both efficient performance and proper maintenance. Every component is designed to fulfill a specific function, contributing to the overall effectiveness of the equipment. A deeper look into the role of each part helps identify how they work together and why their precise operation is crucial for smooth functioning.

Main Operational Components

The core components are responsible for driving the system’s overall performance. These elements ensure that the flow of energy, fluid, or air is controlled and directed precisely where it is needed. They include essential mechanisms that control movement, pressure, and the transfer of force, all of which are necessary for achieving optimal output.

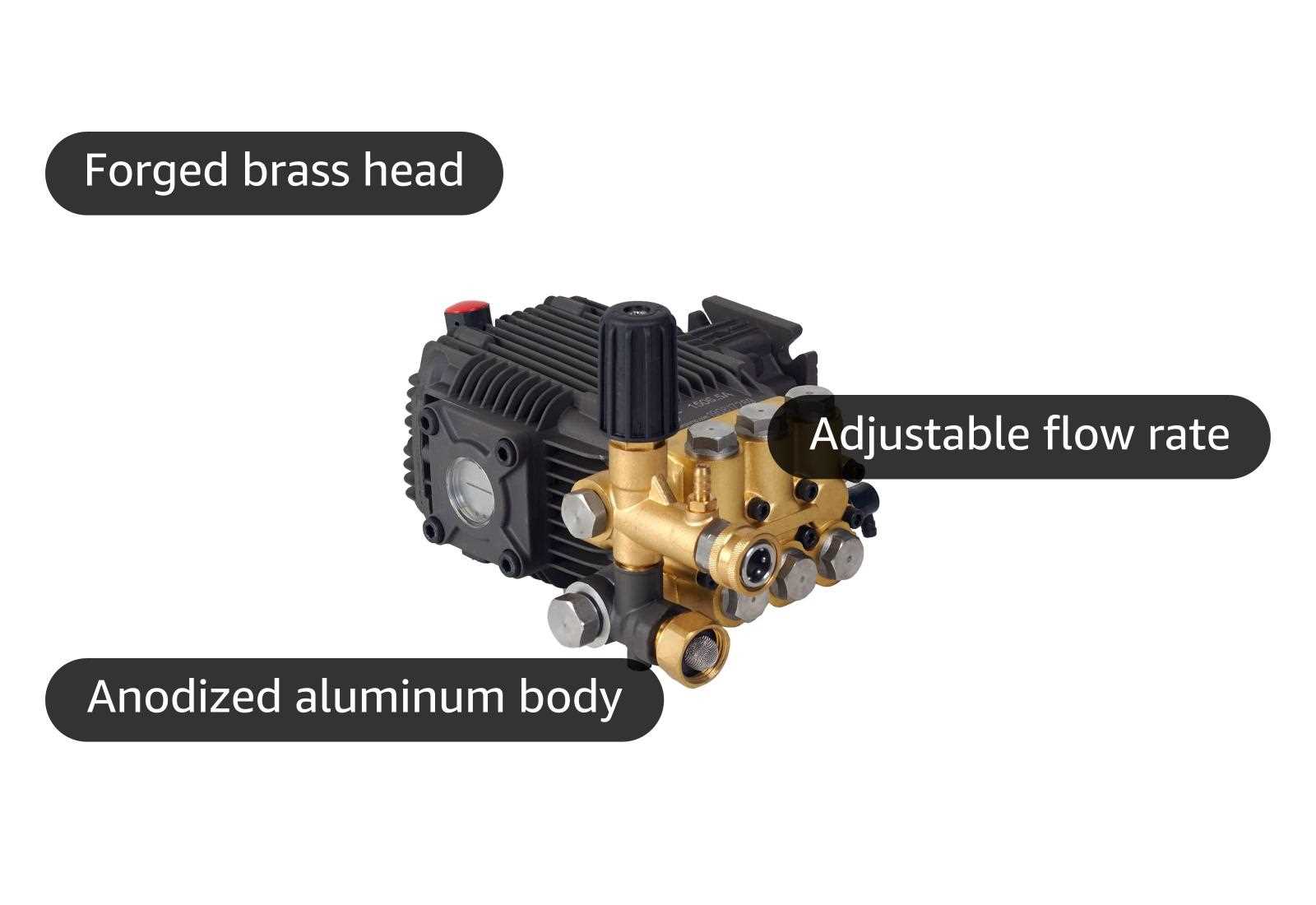

Supportive and Auxiliary Elements

In addition to the primary components, supportive elements also play a vital role in maintaining system efficiency. These parts help regulate functions such as temperature, lubrication, and pressure, ensuring that the primary components operate within optimal conditions. Without these auxiliary elements, the core components could experience unnecessary wear or operational issues, potentially affecting the overall system performance.

How to Maintain Aaa 8.7ga12 Pump Parts

Proper upkeep of any mechanical system is essential for ensuring its longevity and optimal performance. Regular maintenance helps prevent malfunctions and reduces the risk of unexpected breakdowns. By understanding the best practices for maintaining key components, operators can significantly enhance the efficiency and lifespan of the equipment.

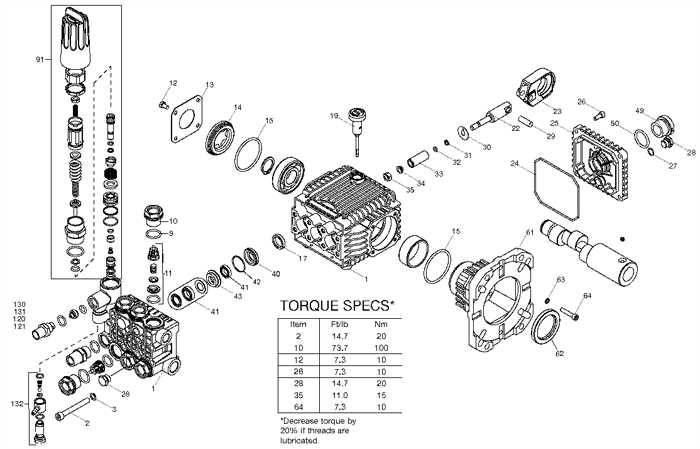

Regular Inspections

Performing routine inspections is the first step in any maintenance program. Checking for signs of wear, corrosion, or damage can identify potential issues early on. It is important to examine both the main and auxiliary components to ensure they are functioning as intended. Regularly cleaning these elements is also crucial to prevent buildup that could lead to blockages or reduced efficiency.

Timely Replacements and Adjustments

Some components may require replacement after a certain amount of use. Identifying parts that are worn or damaged allows for timely adjustments. In addition, recalibrating elements that control pressure, flow, or energy distribution ensures they remain within optimal operating conditions. Proactively replacing parts before they fail helps avoid more serious damage to the system.