Understanding the intricate details of construction machinery is essential for efficient operation and maintenance. When dealing with heavy equipment, knowing each individual part and its function can greatly enhance performance and prevent unnecessary breakdowns. Whether you are a professional mechanic or an operator, being familiar with your machine’s structure will ensure smoother workflows and quicker repairs.

In this guide, we will explore the various elements of an excavator, focusing on their identification, maintenance, and common issues. From hydraulic systems to the mechanical framework, this resource will serve as a valuable reference to help you navigate the complexities of these powerful machines.

Maintaining machinery requires a precise understanding of each component’s role. Regular inspections and knowing where specific parts are located can prevent costly repairs. Through detailed breakdowns and insights, you will gain the confidence to troubleshoot effectively and keep your equipment in optimal condition.

Understanding Excavator Components

When working with large construction machinery, it’s crucial to have a solid understanding of how each element contributes to the overall function. The mechanical system of an excavator consists of numerous interconnected components, each playing a specific role in ensuring smooth operation. Recognizing these components, their placement, and their purpose is vital for both routine maintenance and troubleshooting potential issues.

Key Elements of Excavator Functionality

The core structure of any excavator includes the engine, hydraulic systems, and the digging mechanism. The engine powers the machine, while the hydraulic system drives the movement of the arm and bucket, allowing for efficient digging and lifting tasks. The connection between these systems ensures that the equipment can perform complex operations with precision and ease.

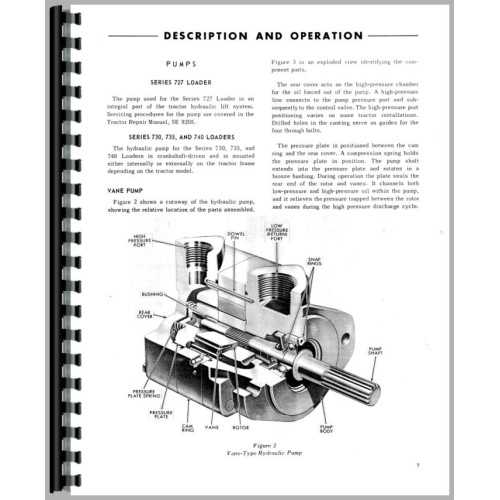

Hydraulic Systems and Their Importance

Hydraulics are the lifeblood of any heavy equipment. These systems use fluid pressure to move parts, providing the force necessary to perform heavy lifting and digging operations. A solid understanding of hydraulic pumps, hoses, cylinders, and valves is essential for anyone working with these machines. Proper maintenance of hydraulic systems can significantly reduce downtime and repair costs.

Familiarity with each component and its function within the overall system allows for better management and longevity of the equipment. Regular inspections and proactive maintenance can prevent failures that would otherwise lead to costly downtime and repairs. Knowing where each part fits within the machine and how they interact ensures smoother operations in the field.

How to Identify Key Components in Excavators

Recognizing the critical components of construction machinery is essential for effective troubleshooting and maintenance. Knowing how to identify and locate each key element ensures that any issues are addressed quickly, preventing delays and costly repairs. With complex systems and multiple parts working in tandem, understanding each component’s function is fundamental to keeping equipment running smoothly.

Essential Mechanical and Hydraulic Systems

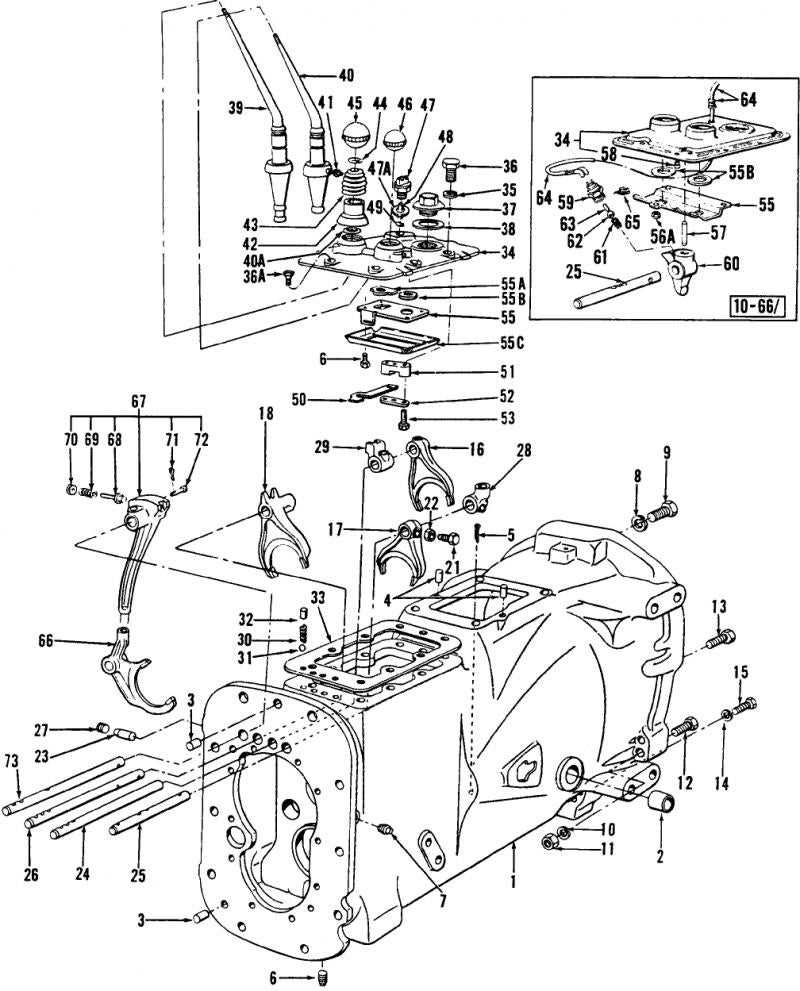

The heart of any large construction vehicle lies in its mechanical and hydraulic systems. These systems are responsible for most of the machine’s movement, from lifting to digging. The engine provides power to the various subsystems, while the hydraulic circuits control the mechanical arms and buckets. To identify these parts, focus on the large cylinders, hydraulic pumps, and valves that manage fluid flow, as well as the engine and transmission that power the entire operation.

Recognizing Wear and Damage Indicators

Damage to critical components often starts subtly. Identifying issues early on can prevent major breakdowns. Check for visible signs such as leaks in hydraulic lines, unusual wear on moving parts, and cracks in structural components. Regular inspections and understanding the normal functioning of each system help operators spot these issues before they escalate.

Being familiar with the layout and function of each essential element enables faster identification and resolution of problems. Whether you’re troubleshooting a loss of power, reduced efficiency, or mechanical failure, knowing where to look and what to inspect first is key to minimizing downtime and ensuring long-term performance.

Maintaining Your Excavator Components

Proper upkeep of construction machinery is crucial for ensuring its longevity and optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances the efficiency of the equipment. By performing routine checks and addressing wear and tear early, you can avoid costly repairs and extend the machine’s service life.

One of the first steps in maintaining heavy equipment is ensuring that all mechanical and hydraulic systems are in top condition. This includes checking for fluid levels, inspecting hoses for leaks, and verifying that all moving parts are properly lubricated. Regularly cleaning these components also prevents dirt and debris from causing damage to the machinery.

Additionally, monitoring the condition of the engine and transmission is essential. Over time, engine parts can wear out, affecting performance. Ensuring that filters are changed, belts are tight, and the cooling system is functioning can significantly reduce the risk of overheating and engine failure.

Lastly, keeping an eye on the structural integrity of the machine is vital. Inspect the frame and undercarriage regularly for signs of rust, cracks, or other damage. Properly maintaining these components ensures that the machine can handle the heavy loads and demanding tasks it is designed for.