When it comes to winter maintenance, having a solid understanding of the key components in your snow clearing machinery is essential. Each part plays a specific role in ensuring smooth operation, and knowing how they fit together can help prevent malfunctions and improve performance. This guide will walk you through the essential elements of the system, offering clear insights into their function and interconnections.

Understanding the layout and structure of these machines allows operators to easily identify potential issues and carry out necessary repairs or adjustments. Whether you are a beginner or experienced user, this knowledge will not only help in routine maintenance but also enable you to troubleshoot effectively when problems arise.

Effective maintenance and proper assembly of these systems depend on knowing where each component fits into the overall machinery. With the right information at your fingertips, you can ensure your equipment is ready for any challenge the season may bring.

Understanding Snow Removal Equipment Components

Every snow-clearing machine consists of multiple essential elements that work together to achieve efficient operation. These individual components, while simple on their own, play critical roles in ensuring the system functions optimally. A clear understanding of each part’s function will help users troubleshoot issues, perform regular maintenance, and enhance overall performance.

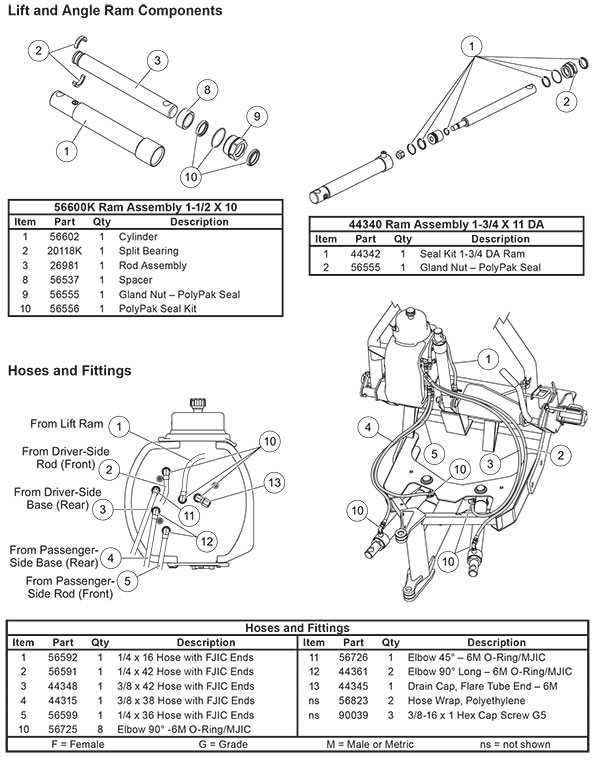

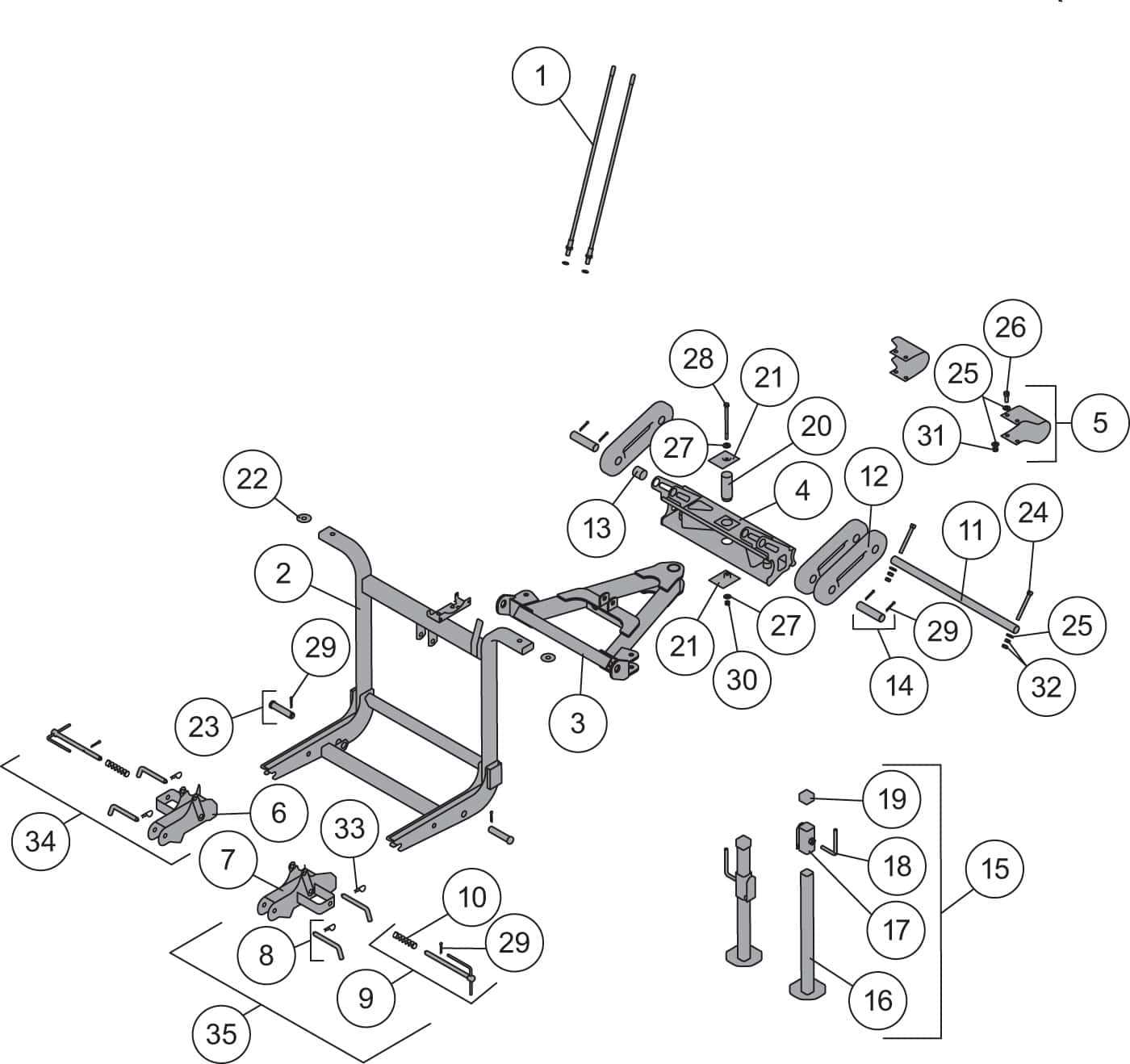

Each section of the equipment, from the hydraulic system to the blade assembly, has a unique purpose. Hydraulic components control movement and adjustment, while the mechanical elements are responsible for the attachment and stability of the working parts. Understanding the relationship between these different sections is crucial for both operators and maintenance professionals.

Properly identifying and managing each segment ensures longevity and reliability. Having a comprehensive view of how the components interact with each other will aid in recognizing any weak spots or areas needing attention, preventing unexpected breakdowns during the most critical times.

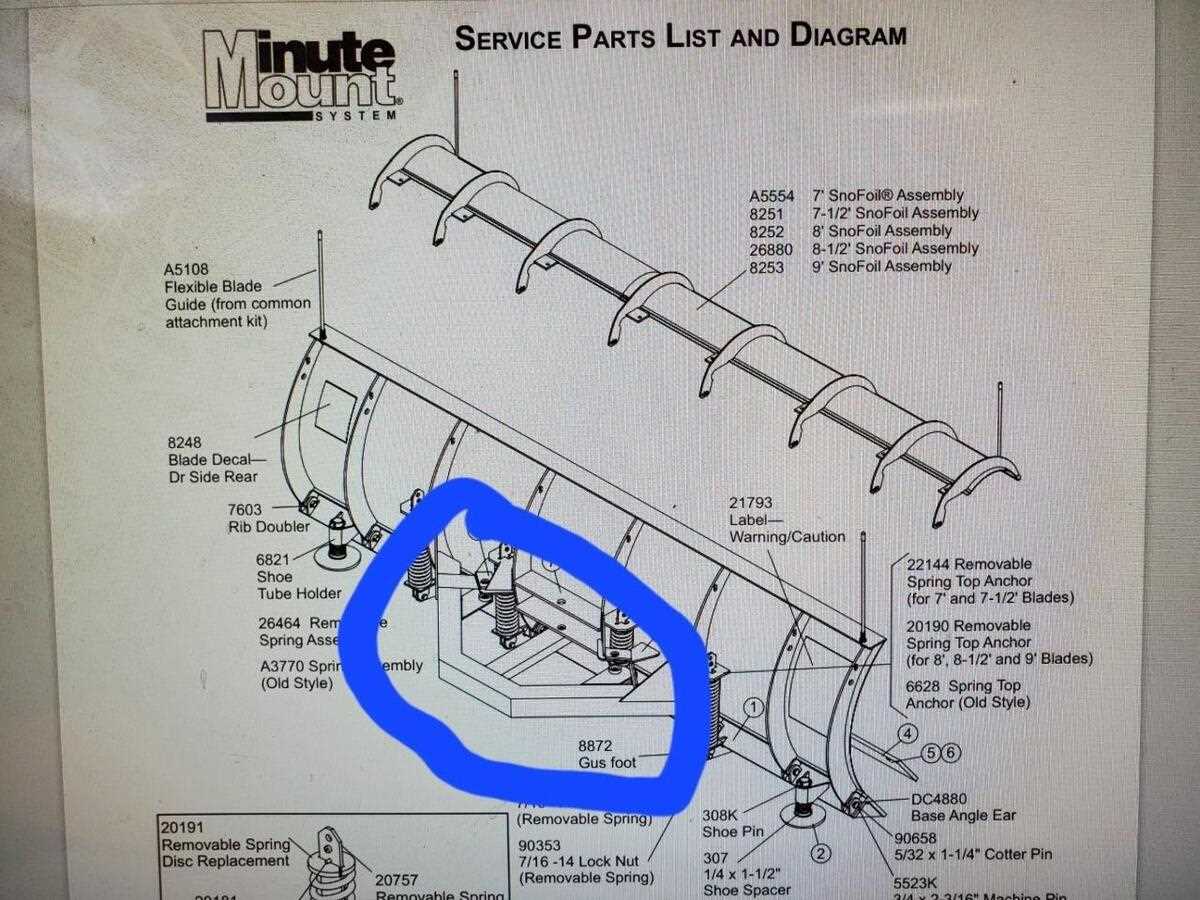

Identifying Key Components in the Diagram

Understanding the layout of a snow removal machine requires a clear recognition of its most important elements. Each section serves a specific function and contributes to the overall performance of the system. Identifying these key components on a visual representation will make it easier to comprehend how the machine operates and where any potential issues may arise.

Some of the most vital sections to focus on include:

- Hydraulic System: Controls movement, adjustments, and lifting capabilities.

- Blade Assembly: Responsible for clearing snow and ensuring proper positioning.

- Frame: The backbone that supports all other components, ensuring stability and durability.

- Control Mechanisms: Allow operators to adjust settings, angles, and positioning of the machine.

- Mounting System: Secures the machine to the vehicle or power unit.

By clearly identifying these major components and their connections, operators can easily navigate the machine’s structure and address specific areas of concern. With each element mapped out, users can also identify parts that may require regular maintenance or replacement.

How to Read a Snow Removal System Layout

Understanding how to interpret the layout of a snow clearing system is crucial for anyone looking to maintain or repair the equipment. These visual guides provide detailed illustrations of each component, showing how they fit together and function as a whole. Knowing how to read these layouts ensures that operators can identify parts, troubleshoot issues, and perform necessary maintenance accurately.

Step 1: Identify Key Components

The first step in interpreting the layout is to familiarize yourself with the primary components. These are often labeled, and understanding what each symbol or line represents will help you navigate the diagram effectively. Look for sections that indicate the major systems like hydraulics, mechanical connections, and mounting hardware.

Step 2: Understand Connections and Flow

Once you’ve identified the components, focus on how they connect and interact. Follow the lines or arrows that indicate movement or fluid flow. These paths often reveal how energy or control signals are transmitted between parts, which is vital for diagnosing operational issues or understanding system adjustments.

Step-by-Step Guide for Beginners

For those new to snow removal equipment, learning how to navigate its components and systems may seem overwhelming. However, breaking down the process into manageable steps can help you get a clear understanding of how everything functions together. This guide provides a structured approach to mastering the basics, ensuring that you can operate and maintain your equipment with confidence.

Step 1: Familiarize Yourself with Basic Components

Start by identifying the primary sections of the machinery. These include the main frame, hydraulic system, and the clearing mechanism. Recognizing these parts and understanding their general functions is the first step toward mastering the equipment. Focus on understanding the role of each major component before diving into the more intricate details.

Step 2: Learn How to Use the System

Once you’re comfortable with the key components, focus on how to operate the machine. This involves understanding control mechanisms and adjusting settings for different conditions. Practicing basic maneuvers and becoming familiar with the adjustments will allow you to handle the equipment safely and efficiently, ensuring optimal performance during snow clearing operations.

Maintaining Your Snow Removal System

Regular maintenance is essential to ensure the longevity and efficiency of your snow clearing machinery. Performing consistent checks and addressing any wear or damage early can prevent costly repairs and ensure that the system operates at its best when needed most. This section outlines key practices for keeping your equipment in optimal condition.

Inspecting key components regularly is crucial. Focus on the hydraulic lines, electrical connections, and moving parts. Check for any signs of wear, leaks, or corrosion that could affect the system’s performance. Cleaning these components after use also helps prevent build-up, which can cause malfunction over time.

Lubrication is another critical aspect of maintenance. Apply the appropriate lubricants to moving parts to reduce friction and prevent damage. Regularly servicing the hydraulic system and ensuring fluid levels are adequate will keep the system running smoothly during operations.