When it comes to maintaining and repairing your cleaning machine, having a clear view of its internal structure is essential. A detailed illustration of its individual components can make troubleshooting and repairs much easier. Whether you’re looking to replace a worn-out piece or simply ensure everything is functioning properly, understanding the breakdown of each section is crucial for the longevity of your tool.

Identifying each part and its function within the overall system will allow you to address issues efficiently. It’s important to know how each component works together to ensure smooth operation. By carefully examining this breakdown, you can prevent potential malfunctions and avoid unnecessary repairs.

Common problems often stem from small but significant wear and tear, and having the right parts at hand can save you time and effort. Understanding where these parts fit into the larger mechanism ensures you can handle any issue that arises with confidence.

Understanding Husky Power Washer 1750 Components

Every cleaning device consists of various elements working in harmony to provide efficient performance. Identifying these parts and their specific functions is crucial for understanding how the machine operates and diagnosing any issues that may arise. By examining the system’s key components, you gain the knowledge necessary for proper maintenance and repairs, ensuring the longevity and reliability of your equipment.

Key Components and Their Functions

At the core of the machine are several vital components, such as the motor, pump, and hose connections. Each piece plays an essential role in ensuring that the equipment performs effectively. The motor powers the system, while the pump generates the necessary pressure for cleaning tasks. Understanding the purpose of each part allows you to troubleshoot efficiently when problems occur.

Maintaining Proper Functionality

Regular inspection of individual components can help identify potential issues before they affect performance. A clogged nozzle, worn-out seals, or damaged hoses are common issues that can hinder the machine’s operation. Knowing how to detect and replace these components will save time and prevent costly repairs in the future.

How to Identify Parts in the Diagram

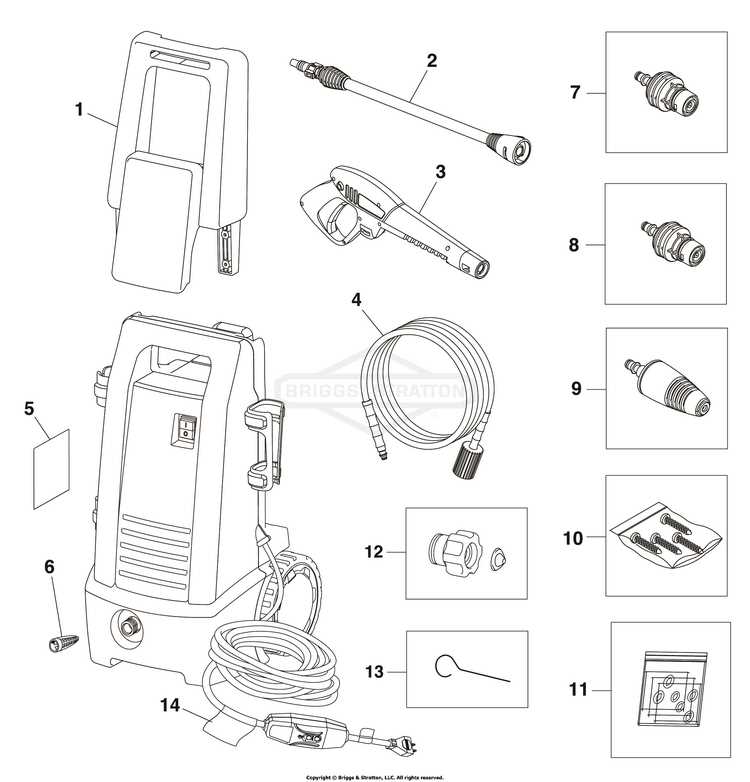

Understanding the visual representation of your cleaning machine is a critical step in recognizing each individual element. A detailed illustration allows you to visually connect each component to its function, making identification easier. By carefully analyzing this image, you can quickly pinpoint the pieces that need attention or replacement.

Breaking Down the Visual Elements

Most illustrations are organized in a way that shows the relationship between each component. Typically, the parts are numbered or labeled, providing an easy reference for understanding where each piece fits into the machine. Pay close attention to these markings and look for any inconsistencies that might indicate wear or damage.

Matching Components to the Manual

Once you’ve identified a part, it’s important to cross-reference it with the user manual. Manuals often provide additional context about each element’s purpose and how to replace it if necessary. This cross-referencing ensures you’re using the right part for any repairs and helps you avoid errors during maintenance tasks.

Common Issues and Part Replacements

Machines often experience wear and tear over time, leading to specific issues that require addressing. Recognizing these problems early and understanding which components need to be replaced can prevent further damage and restore the machine’s functionality. Knowing which parts commonly fail allows you to act swiftly and avoid costly repairs.

Frequent Problems and Their Causes

One of the most common issues is a loss of pressure, which can result from a clogged nozzle or a malfunctioning pump. Over time, seals can degrade, leading to leaks or reduced performance. Hoses may also suffer from cracks or blockages that restrict water flow. Identifying the root cause of these problems ensures that you replace the correct parts, getting your equipment back in working order quickly.

Replacing Worn-out Components

When a part becomes damaged or stops working altogether, it’s essential to replace it promptly to avoid further disruption. For example, if the nozzle is clogged, cleaning or replacing it can restore the spray’s effectiveness. Likewise, checking the seals for any wear can prevent leaks from developing. Always ensure you use the correct replacement parts to maintain optimal performance.