When it comes to maintaining power equipment, having a clear understanding of its internal components is essential for effective repairs and upkeep. Knowing how each piece interacts with the others allows for better diagnosis of issues and more informed decisions when replacing or fixing parts. This knowledge is crucial for both beginners and experienced users alike.

Proper maintenance relies on identifying specific sections within the mechanism, each serving a unique function. From the engine’s core elements to the peripheral accessories, a detailed view of these components ensures you can address any problem with confidence. Whether you’re dealing with wear and tear or performing routine care, understanding the individual functions of each part can significantly improve the lifespan and performance of your tool.

Effective repair starts with a comprehensive understanding of how everything fits together. Whether you’re troubleshooting an issue or upgrading your equipment, having access to a clear layout of internal components will guide your efforts. This ensures that every repair is carried out efficiently, minimizing downtime and ensuring the machine performs at its best.

Understanding Internal Components of Your Tool

To effectively maintain and repair your power equipment, it is essential to familiarize yourself with its internal structure. Each individual component plays a vital role in ensuring smooth operation, and understanding how they function together helps in troubleshooting and performing repairs. With knowledge of these elements, users can more easily identify problems and carry out necessary adjustments or replacements.

From the engine’s main assembly to auxiliary elements, every section of the mechanism has a specific purpose. Some parts are designed to control power transmission, while others handle the fuel intake, lubrication, and cooling systems. A clear understanding of how these components interact enables better care and ensures that the tool runs optimally for a longer period of time.

Regular maintenance and timely repairs become much more manageable when you know the names, locations, and functions of the various elements inside the equipment. Whether performing basic tasks such as cleaning or more involved procedures like replacing worn-out components, this knowledge significantly enhances efficiency and results.

How to Read a Chainsaw Parts Diagram

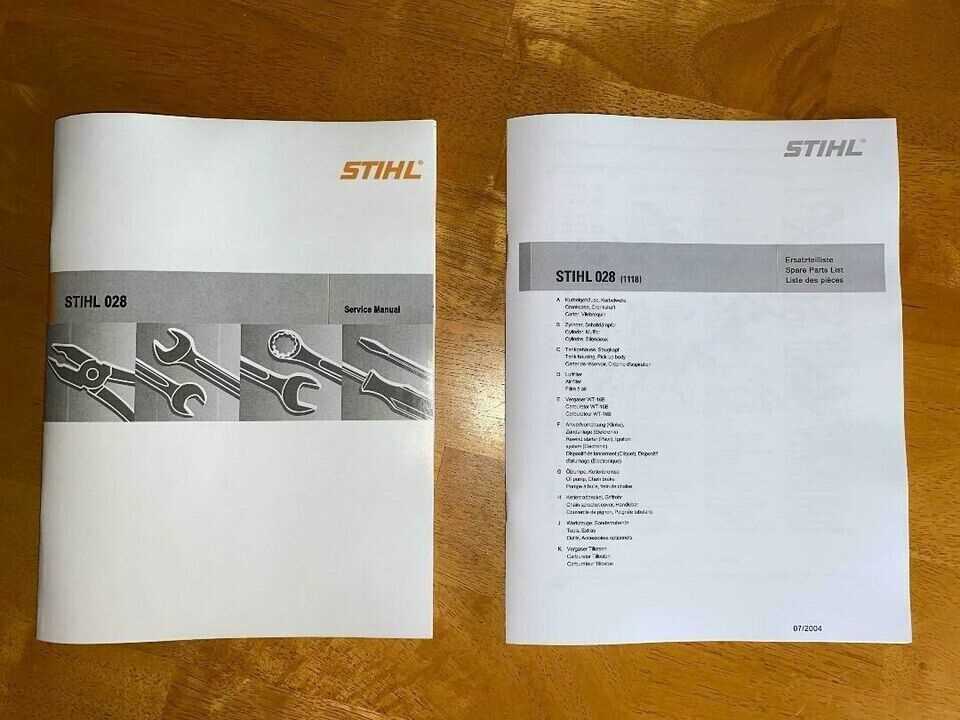

Understanding how to interpret a visual representation of your equipment’s internal components is a critical skill for proper maintenance. A clear and detailed schematic serves as a guide for identifying specific elements and their functions. By learning how to read this type of illustration, you can quickly locate and assess individual components, making repairs and replacements more efficient.

Each section of the drawing is typically labeled with both part names and corresponding numbers. These references allow you to easily match the components shown with the actual parts you may need to repair or replace. It is important to focus on key areas, such as the power transmission system, the engine’s internal parts, and the surrounding accessories. Carefully examine the layout and pay attention to any annotations that describe how pieces fit together and work in tandem.

Properly analyzing the illustration ensures that you don’t overlook crucial components. It helps in making informed decisions, whether you’re troubleshooting a malfunction or performing a full rebuild. With practice, the ability to read such guides will become an indispensable tool for anyone looking to maintain their equipment at optimal performance levels.

Essential Spare Parts for Equipment Maintenance

Proper upkeep of your power tool requires access to a variety of essential replacement components. Regular wear and tear can lead to the degradation of certain parts, so having a set of spare components on hand ensures smooth operation and minimizes downtime. Understanding which parts are most crucial for maintenance helps you prioritize replacements and make informed decisions when it’s time to service your equipment.

Key Components for Regular Maintenance

Among the most frequently replaced elements are those responsible for the tool’s power delivery and fuel system. Items such as the air filter, spark plug, and fuel lines are critical for ensuring proper function. Regularly checking and replacing these parts can prevent a lot of common issues and improve overall performance.

Accessories for Enhanced Performance

Additional components, like the guide bar and sprocket, also require attention, especially if your tool is used regularly. These accessories play a significant role in the tool’s efficiency and precision. Over time, they may experience wear, so keeping a few spares in your toolkit will help you avoid interruptions in your work.