Understanding the inner workings of complex mechanical systems is essential for proper maintenance and repair. The Zf system, widely used in various watercraft, consists of several interconnected elements that work together to provide smooth and efficient operation. Each component has a specific role that contributes to the overall functionality of the system.

In this section, we will explore the crucial elements that make up the Zf assembly. By gaining a deeper understanding of their design and function, you can better maintain and troubleshoot the system. Whether you are a technician or a boat owner, knowing how these components interact can help you ensure optimal performance and longevity.

Understanding Zf System Components

Efficient operation of any vessel requires a detailed understanding of the key elements involved in its propulsion system. These components, though varied in function and design, work together to ensure seamless performance under different conditions. Identifying and knowing the purpose of each part is essential for effective maintenance and troubleshooting.

Essential Elements of the Zf Setup

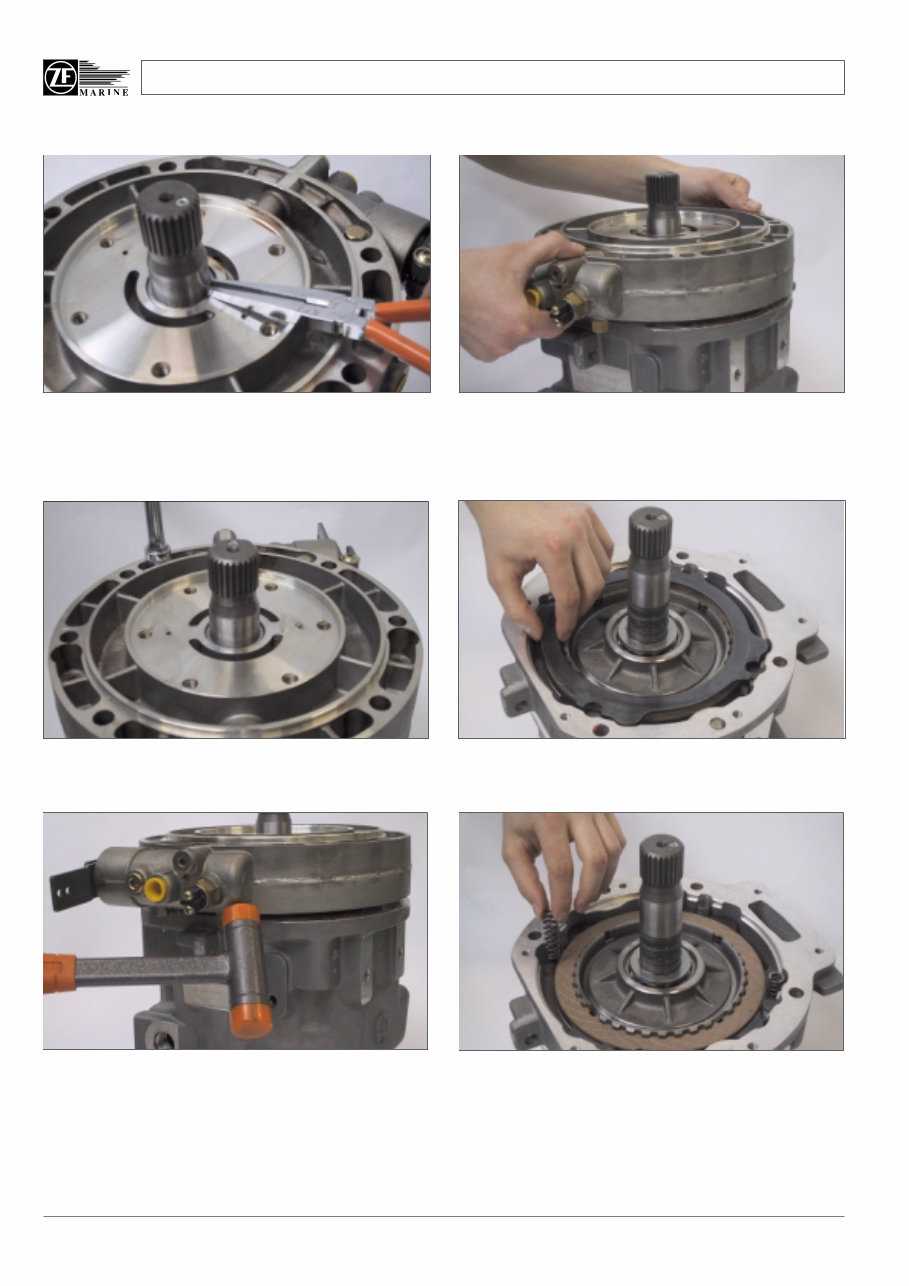

The Zf system incorporates a range of vital elements, including gears, shafts, and clutches, that control power distribution. These parts enable the vessel to move smoothly and respond accurately to changes in throttle and speed. Each component plays a role in optimizing performance while minimizing wear and tear.

How Each Component Interacts

The interaction between these individual elements determines the overall efficiency of the setup. For instance, the way gears mesh with shafts impacts the vessel’s speed, while clutches ensure smooth shifts between gears. Understanding this synergy is crucial to diagnosing issues and performing effective repairs or upgrades.

Key Parts of Zf Systems

To ensure the proper functioning of a vessel, it is crucial to understand the critical components involved in the power transfer mechanism. These elements work together to regulate the movement and responsiveness of the craft, allowing for smooth operation under various conditions. Each component must be in top condition for optimal performance and longevity.

Main Components of the System

The central elements of the Zf setup include the gears, shafts, and coupling mechanisms. Gears facilitate the transfer of power, while shafts provide the necessary link between the engine and the propulsion system. The coupling parts, such as clutches and torque converters, allow for smooth gear shifts and help in adapting to different operational speeds.

Supporting Elements and Their Functions

Additional elements such as bearings, seals, and lubricating systems play a supporting role in the efficient functioning of the system. Bearings reduce friction, ensuring smooth rotation, while seals prevent leakage and maintain the integrity of the internal components. Lubricants keep parts functioning smoothly by reducing wear and heat buildup during operation.

How Zf Systems Function

The efficient operation of a vessel’s propulsion system relies on the coordinated action of several key elements that manage power transfer from the engine to the propeller. These components work in unison to provide smooth movement and responsiveness, allowing for precise control over speed and direction. Understanding how these parts interact is vital for maintaining system performance and diagnosing potential issues.

The Role of Gears and Shafts

At the core of the Zf system, gears and shafts are responsible for transmitting power. The gears adjust the ratio between engine speed and propeller speed, allowing the vessel to move efficiently at different RPMs. The shafts connect the engine to the propulsion components, ensuring that power flows smoothly from one part to the next, enabling the craft to achieve the desired velocity.

Clutch Systems and Power Distribution

Clutches and torque converters play a critical role in enabling smooth gear shifts and adapting to varying operating conditions. These mechanisms allow for seamless transitions between different speeds and reduce the shock load on the system. By regulating how power is distributed, the clutch system ensures that the vessel maintains consistent performance without jerky movements or disruptions in power delivery.