Maintaining outdoor machinery requires a clear understanding of how each individual element functions together. When troubleshooting or performing repairs, a visual representation of the equipment’s key components can be incredibly useful. This guide aims to help you familiarize yourself with the essential parts of your machinery and their specific roles.

Knowing the layout of each component allows for more efficient maintenance and repair tasks. It enables users to identify any faulty elements quickly, reducing downtime and enhancing the longevity of the equipment. Understanding this framework is crucial, especially for those who prefer DIY fixes or want to improve their technical knowledge.

By learning to interpret these technical drawings, you can gain confidence in working with your equipment. Recognizing each part’s location and purpose simplifies the repair process, ensuring you can take proactive steps before minor issues turn into significant problems.

Understanding Snow Removal Equipment Components

Effective snow removal machinery relies on a well-designed structure where each element plays a crucial role in the overall operation. Familiarity with the machine’s key components is essential for maintenance and troubleshooting. Knowing where each part fits and its function will help ensure optimal performance and quick resolution of any issues.

Key Components to Know

Among the various elements of the equipment, the engine is the powerhouse, driving the entire system. The auger, designed to break apart and move the snow, works in tandem with the chute mechanism that directs the output. Each part needs to be maintained and serviced regularly for reliable performance, especially during harsh weather conditions.

Maintenance and Troubleshooting

Regular checks are vital to prevent wear and tear. Monitoring the health of the drive system, belts, and other moving components can help detect potential failures before they escalate. With proper care and understanding, users can extend the life of their equipment and ensure it continues to operate smoothly throughout the winter season.

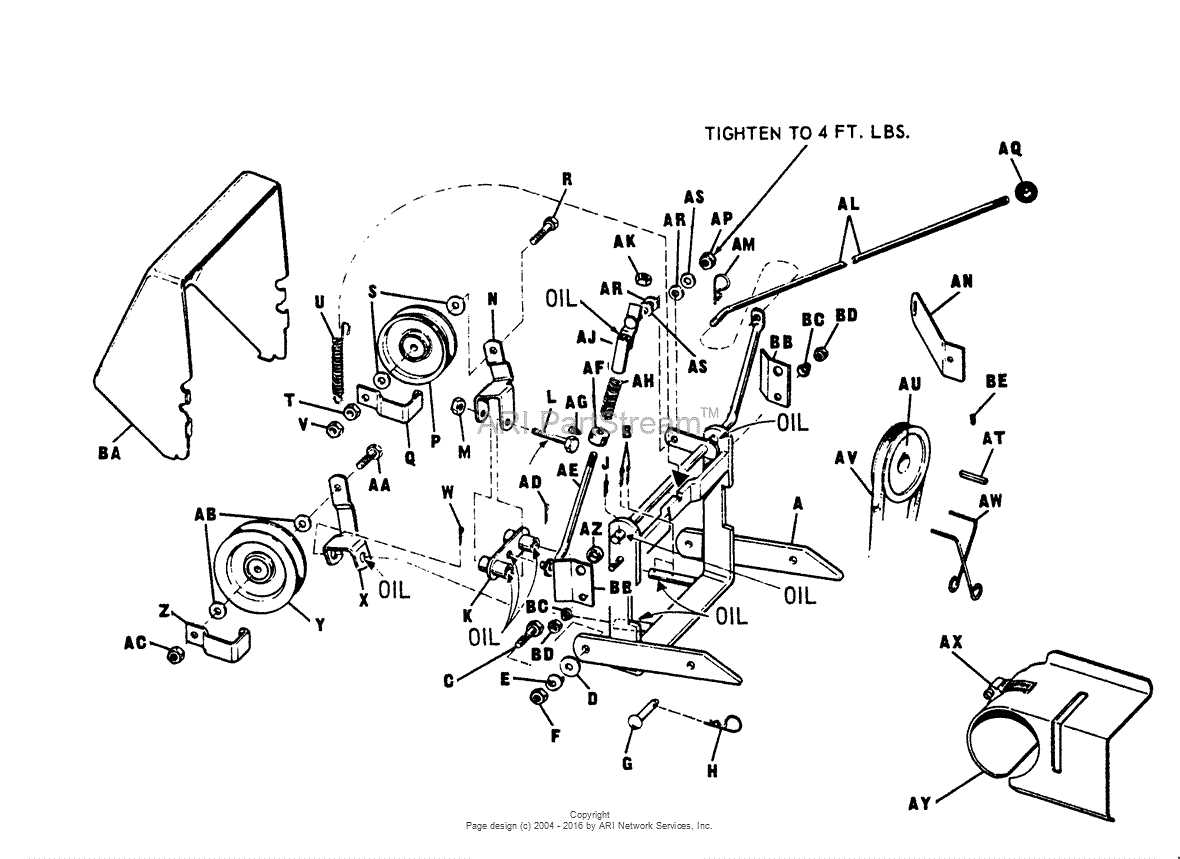

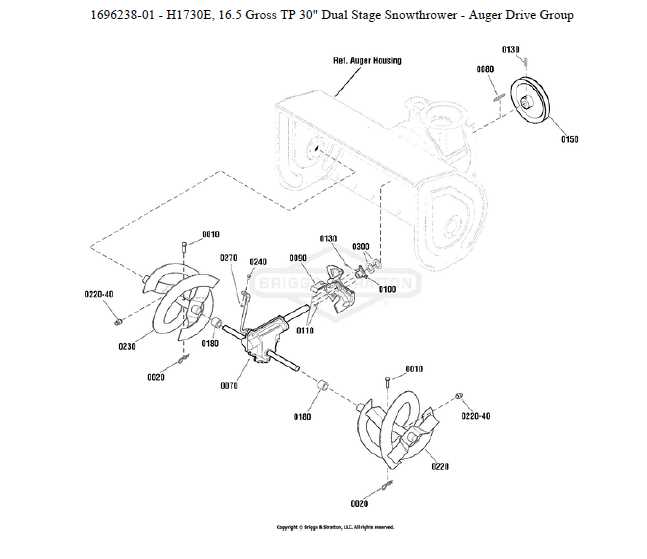

How to Read Equipment Component Schematics

Understanding the layout of your machine through visual representations can significantly simplify maintenance and repairs. These schematics provide an organized view of the equipment’s structure, showing how various elements are interconnected. Learning to interpret these drawings is essential for identifying specific parts and their relationships within the whole system.

Follow these steps to effectively read and utilize schematics:

- Identify key sections: Look for labels that categorize major components such as the engine, drive system, and control mechanisms.

- Understand part numbers: Each part is often assigned a unique number. Make sure to cross-reference these with the provided list to match them with the correct components.

- Examine connections: Focus on lines or arrows that show how parts are connected or interact with each other. This will help you understand the machine’s overall functionality.

By following these guidelines, you can gain a better understanding of your equipment’s internal structure, making repairs and replacements much more efficient.

Common Issues with Snow Removal Equipment

Even the most reliable outdoor machinery can experience problems over time. Understanding the most common issues that arise with this type of equipment can help users troubleshoot and address malfunctions promptly. Regular maintenance and being aware of potential failures can extend the life of the machine and improve performance in challenging conditions.

Some of the typical problems that owners may encounter include:

- Engine starting issues: One of the most frequent concerns is difficulty starting the engine. This could be caused by a variety of factors such as clogged fuel lines or issues with the spark plug.

- Drive system failure: A malfunction in the drive system, such as slipping belts or broken gears, can make it impossible for the machine to move forward or reverse properly.

- Clogging or jamming: When the chute or auger becomes blocked with debris or ice, it can prevent the equipment from functioning effectively, often leading to a slowdown in performance or complete failure.

Recognizing these common issues and taking the necessary steps to resolve them can help ensure your equipment continues to run smoothly throughout its service life.