When working with remote-controlled vehicles, a clear understanding of their individual components is essential for both assembly and maintenance. This guide provides a detailed look at the various elements that make up these models, helping enthusiasts and professionals alike navigate the complexities of their construction and upkeep.

Whether you’re assembling a new model or repairing an existing one, knowing where each part fits and how they interact can make a significant difference in performance. This resource aims to simplify the process, offering a clearer view of the relationships between different elements of the vehicle.

Mastering the assembly process is crucial for ensuring that each component functions correctly, leading to a more efficient and enjoyable experience. By understanding the connections between the different parts, you’ll be better equipped to tackle both minor repairs and major upgrades with confidence.

Understanding the Vehicle Components

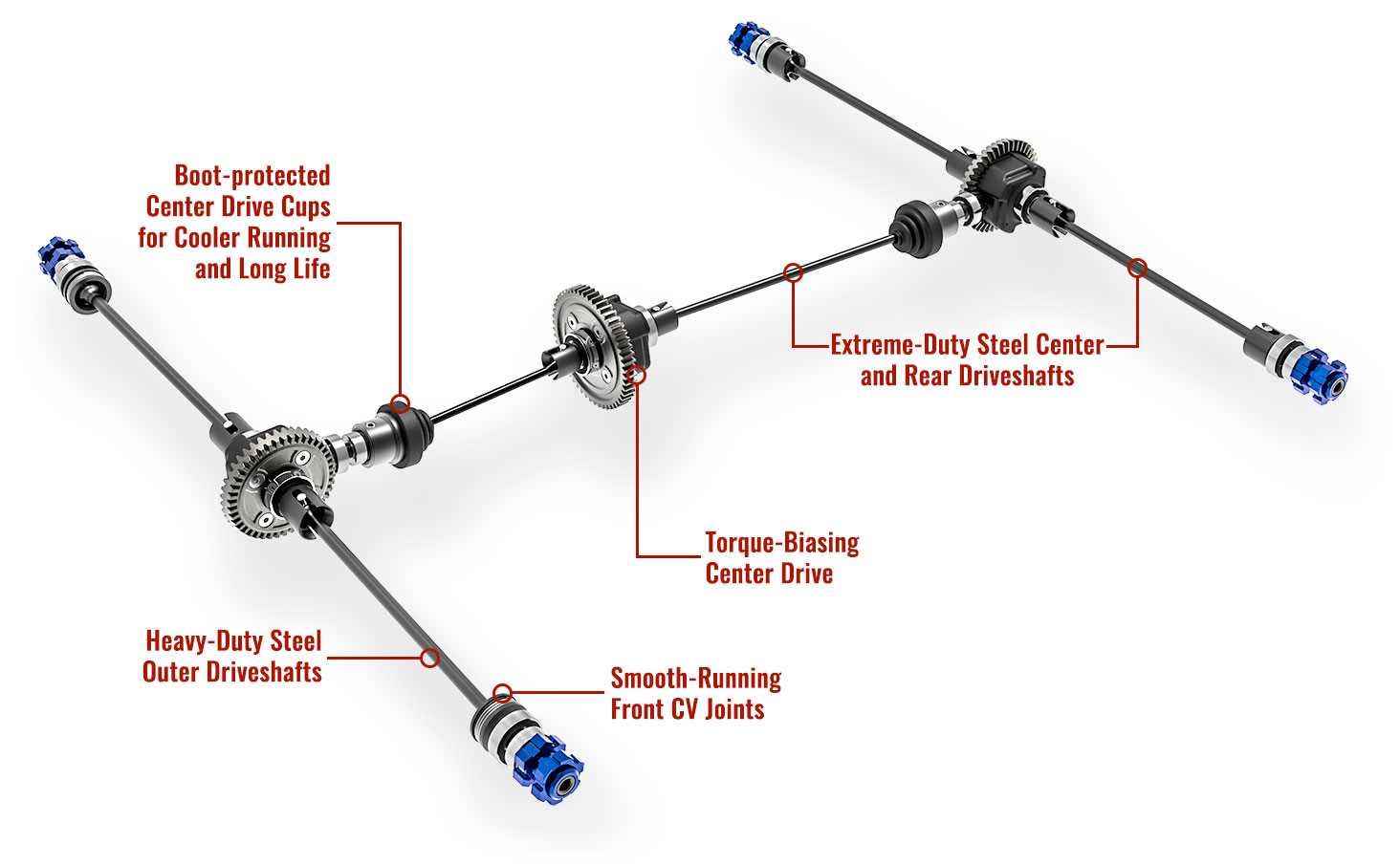

To fully comprehend how a remote-controlled vehicle operates, it’s important to understand the different elements that make up its structure. Each individual piece plays a crucial role in ensuring the model performs efficiently, whether on rough terrain or during high-speed runs. The vehicle’s framework, motor systems, suspension, and electronic components are all intricately connected, and recognizing their functions allows for easier maintenance and customization.

Breaking down the various segments of the vehicle, such as the chassis, drivetrain, and control electronics, provides valuable insight into the overall assembly. These components must work in harmony to achieve optimal performance, and understanding their individual roles helps when diagnosing issues or upgrading specific areas. By knowing how each piece fits together, you’ll be better prepared to handle repairs and improvements as needed.

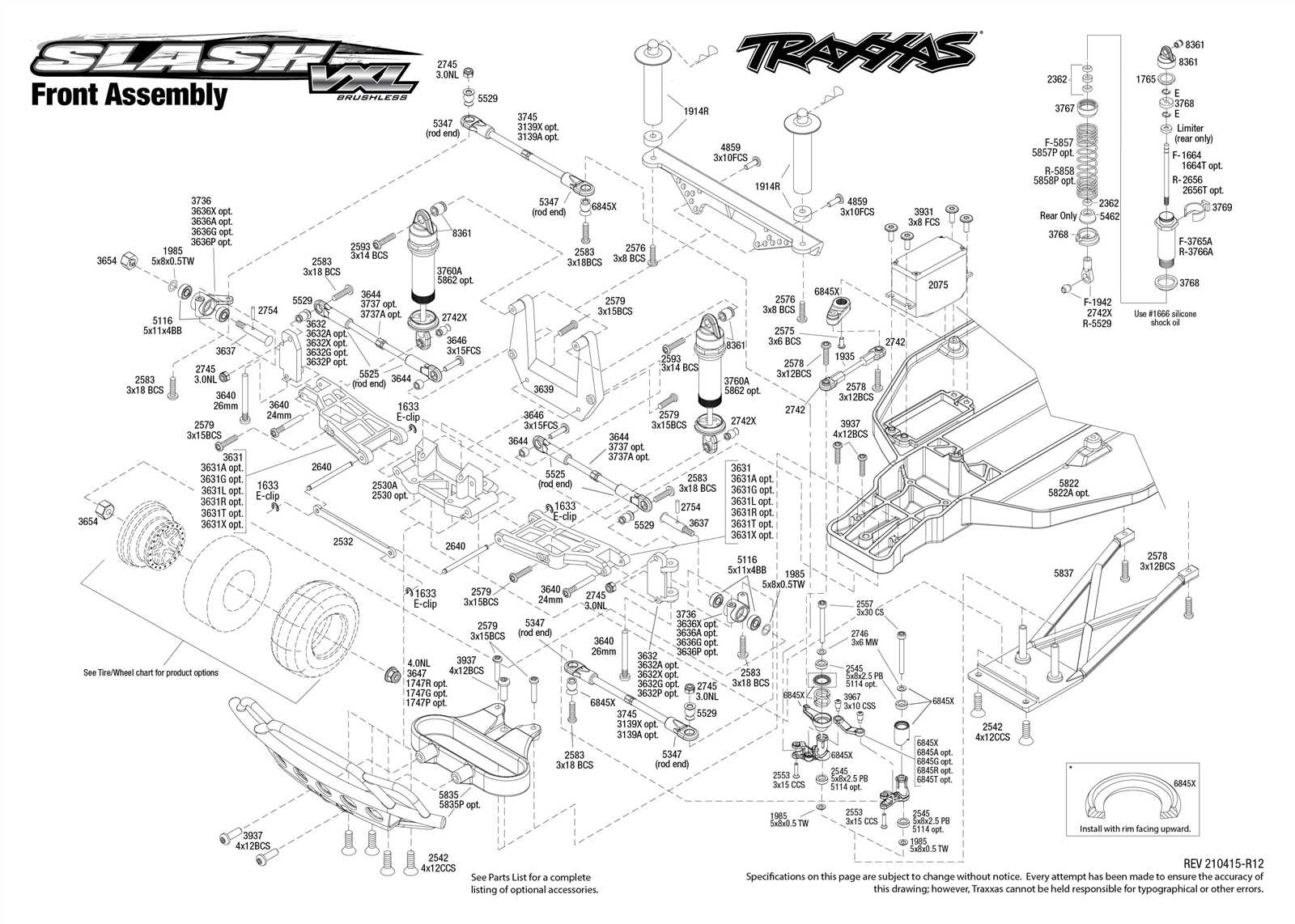

How to Interpret the Assembly Blueprint

Understanding an assembly blueprint is a key step in ensuring successful vehicle construction or repair. These illustrations provide a visual representation of how different elements are positioned and connected within the model. By interpreting these drawings correctly, you gain a clear understanding of the necessary steps to assemble or disassemble the vehicle, facilitating repairs or modifications with ease.

Each symbol and line on the blueprint corresponds to specific parts and connections, making it crucial to recognize the role of each detail. Pay close attention to the numbering system and labels that help identify the components. Knowing how to read these markings ensures you follow the correct sequence and understand where each piece fits, reducing the likelihood of errors during assembly.

Mastering the art of interpreting assembly guides enhances your ability to work on the model confidently. With the right knowledge, you can pinpoint issues faster, source the correct components, and successfully complete projects or repairs on time.

Essential Tools for Vehicle Assembly

When assembling a remote-controlled vehicle, having the right tools at hand is crucial for efficient and precise work. The proper instruments allow for smooth handling of the assembly process, ensuring that each component fits together perfectly. Using the correct tools also helps prevent damage to sensitive parts and ensures that everything is properly secured for optimal performance.

Key tools such as screwdrivers, pliers, and hex wrenches are fundamental to assembling the various mechanical components. Additionally, having a work surface that allows for easy access to these tools and a well-organized parts tray can make the process more efficient. Investing in high-quality instruments ensures that the vehicle is assembled correctly, reducing the risk of errors that could lead to malfunctions down the line.

In addition to basic tools, specialized instruments such as thread lockers and precision measuring devices are useful for more advanced steps. Having a complete toolkit ensures that you’re ready to tackle any challenges that may arise during assembly or maintenance, providing the best foundation for a successful project.