Having a comprehensive overview of the essential elements of heavy machinery is crucial for ensuring efficient operations and proper upkeep. Knowing how different components fit together allows for smoother repairs, replacements, and overall maintenance.

The layout of a machine provides an essential guide for understanding the relationship between its individual sections. By studying how each element interconnects, users can more effectively troubleshoot issues and identify the source of malfunctions.

Accurate identification of each part and its function can make a significant difference when performing repairs. With this knowledge, it becomes easier to prevent costly errors and ensure the longevity of the equipment. This resource is designed to offer insights into how to approach these tasks with confidence.

Exploring the Assembly Components

Understanding the individual elements that make up complex machinery is key to maintaining its functionality. Each component plays a distinct role in the overall operation, and knowing their specific functions ensures proper care and troubleshooting. In this section, we will look into the main sections of the machine and how they contribute to its performance.

Mechanical Structure

The mechanical structure serves as the foundation, supporting all other components. Key elements such as the engine, transmission, and frame are interconnected, working together to provide the necessary power and stability. Understanding how these pieces fit and operate will guide any adjustments or repairs needed to maintain the machine’s strength and efficiency.

Operational Components

Beyond the structural components, operational parts like the hydraulic system and control mechanisms are crucial for performing various tasks. These systems rely on precise coordination to execute actions effectively. Recognizing how each piece of equipment works together can help avoid operational failures and ensure smooth functionality during usage.

Overview of Key Mechanical Parts

In any complex machine, several critical components work in harmony to ensure smooth performance and long-lasting durability. Understanding these key elements is vital for anyone looking to maintain or repair the equipment efficiently. This section highlights the most important mechanical features that contribute to the machine’s overall functionality.

The engine, as the power source, is often regarded as the heart of the system. It provides the necessary energy to drive other parts and enable movement. Alongside it, the transmission system plays a crucial role in transferring that energy to various functions, allowing for controlled operations. The chassis, acting as the frame, offers structural support, ensuring stability during operation. Together, these elements form the backbone of the machine, enabling it to perform its intended tasks effectively and reliably.

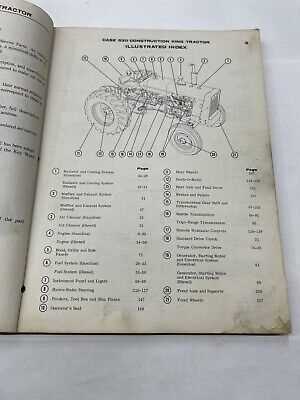

How to Read the Assembly Layout

Interpreting an equipment layout is essential for understanding how each element fits together. These visual representations serve as a valuable tool to identify the various components and their relationships. In this section, we’ll discuss how to approach these layouts, making it easier to locate specific features and troubleshoot issues.

Understanding Symbols and Labels

Most layouts use a standardized set of symbols to represent each part. It’s important to familiarize yourself with these visual cues, as they help quickly identify components. Key labels are usually placed next to or within the shapes representing parts. These may include:

- Part numbers to help locate replacement items.

- Connection points indicating where parts interact.

- Functional details highlighting the role of each component.

Tracing the Interconnections

Once familiar with the symbols and labels, the next step is to follow how the parts are connected. Look for lines that represent physical links between components. These connections are essential for understanding how energy flows through the system and how each element contributes to the overall performance. Key things to look for include:

- Flow directions showing the movement of power or materials.

- Interdependence between parts that rely on each other to function.

- Integration where multiple systems are connected for a common purpose.

Decoding Symbols and Labels

Understanding the symbols and labels used in mechanical schematics is crucial for interpreting how the equipment functions. These visual markers provide essential information that simplifies the identification of components and their relationships. This section will guide you through the process of recognizing and decoding these symbols to enhance your understanding of the layout.

Key Symbols to Identify

Each layout uses a set of standardized symbols to represent various elements within the system. These symbols may vary slightly depending on the manufacturer, but they generally follow a recognizable pattern. Common symbols include:

- Circles and squares often represent power sources or control units.

- Arrows indicate the flow of energy or materials within the system.

- Lines show physical connections between different components.

Understanding the Labels

Along with symbols, labels provide specific details about each element’s function or part number. These may include:

- Part numbers for identifying replacement items.

- Functional descriptions explaining the role of the component within the system.

- Connection points marking where two parts interact.

By becoming familiar with these symbols and labels, you can more easily navigate the layout and gain a deeper understanding of how each part contributes to the overall function of the machine.

Maintenance and Repair Tips

Proper upkeep and repair are essential for ensuring the long-term functionality of any complex machine. Regular maintenance can prevent unexpected failures, while knowing how to troubleshoot and repair components can save time and money. This section provides useful tips on how to maintain and fix the key elements of the system effectively.

Routine Inspection and Cleaning

One of the most important aspects of maintenance is regular inspection. Checking for wear and tear, loose connections, or accumulated debris can prevent many common issues. Cleaning parts that are prone to dirt buildup is also crucial for maintaining smooth operation. Areas to focus on include:

- Air filters to ensure proper airflow.

- Hydraulic components that require regular fluid checks.

- Electrical connections to avoid corrosion or loose wires.

Repairing Damaged Components

If you encounter damage or malfunction, addressing it promptly is key. Follow the manufacturer’s instructions when replacing parts to ensure compatibility and correct installation. For major repairs, it may be necessary to disassemble certain sections of the machine. Always use high-quality replacement parts and check the alignment of components to avoid future issues.