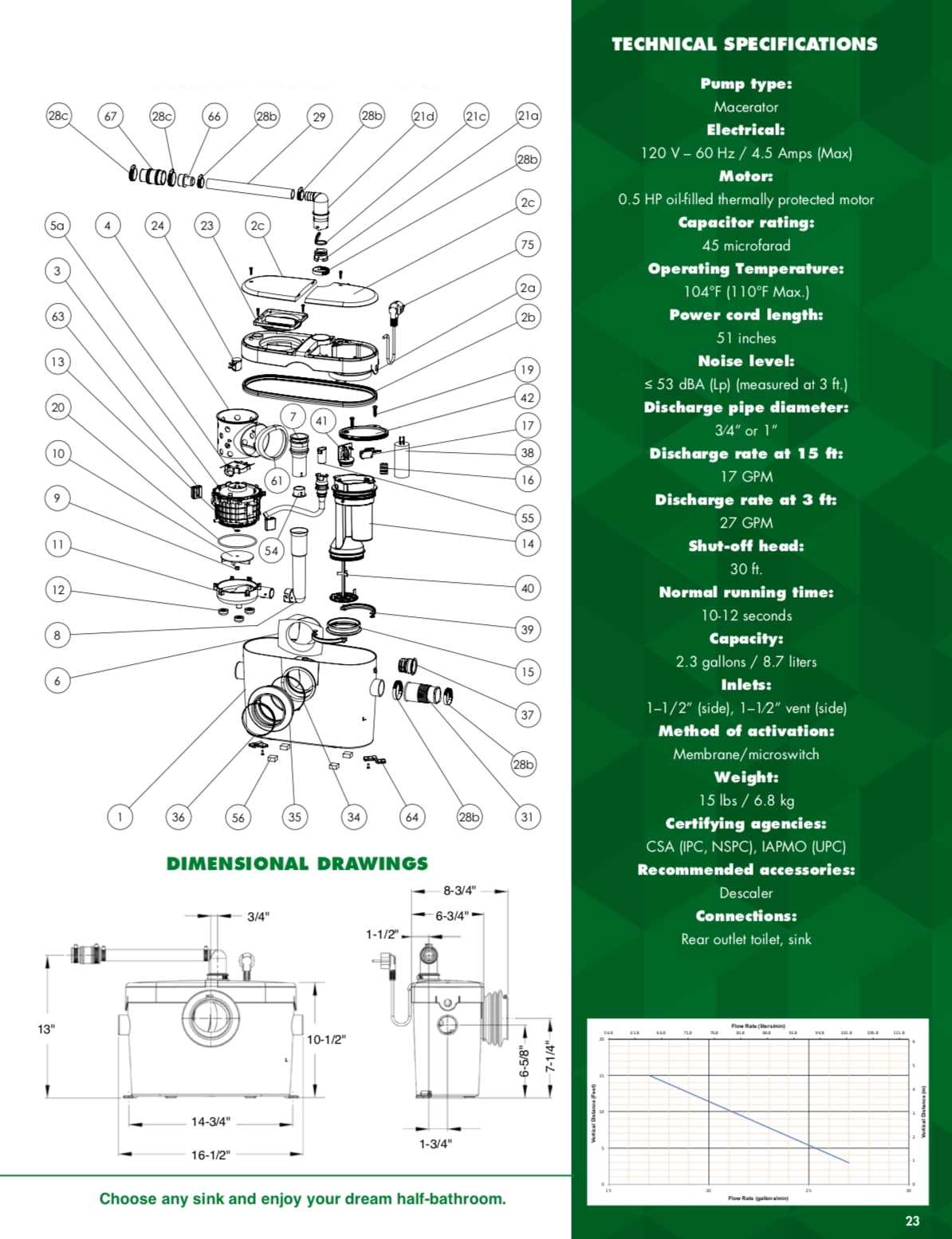

When maintaining a pumping system, it’s essential to have a clear understanding of its internal components and how they interact. Proper knowledge ensures that troubleshooting and repairs are done effectively, saving both time and effort. A detailed overview of the system’s key elements can guide you through any necessary replacements or adjustments.

Identifying the main components is the first step towards efficient system maintenance. By learning about each part’s function and location, you can easily pinpoint issues and make informed decisions. This knowledge also aids in performing routine checks, preventing unnecessary breakdowns.

Once you are familiar with the system layout, repairing or replacing damaged parts becomes much simpler. Familiarity with the configuration allows for swift actions, ensuring minimal disruption to daily operations. A well-maintained system will continue to function smoothly and effectively for years to come.

Understanding the Pumping System Components

To properly maintain a waste removal system, it’s crucial to grasp the different elements that make up the unit. Each component plays a specific role, and understanding how they interact ensures efficient operation. Knowing the key components will help in diagnosing problems and performing necessary repairs.

The core structure of the system consists of a motor, pump, and various connecting parts that allow for the proper movement of waste. These elements work together to move waste from lower areas to higher elevations, enabling smooth functionality. Understanding their individual roles allows you to focus on the area that requires attention during maintenance or troubleshooting.

Routine checks and maintenance are more effective when you’re familiar with the overall design. Having a good grasp of the system’s workings can prevent major issues and keep everything running smoothly. A clear understanding of how each element contributes to the system’s efficiency ensures long-term reliability and durability.

How to Read a System Layout

Understanding a system’s layout is crucial when working with mechanical or plumbing components. A clear visual representation allows you to identify each part’s function, helping you navigate the structure efficiently. Knowing how to interpret these visuals simplifies troubleshooting and maintenance tasks.

Interpreting Symbols and Labels

Each element in a system layout is typically represented by symbols or labels. These visual cues indicate the type of component and its specific function. Learning to recognize these symbols is the first step to understanding the system’s flow and identifying potential issues quickly.

Understanding Connections and Flow

Alongside symbols, understanding the lines and arrows that represent connections is essential. These lines show how the components are connected and how the system’s flow is maintained. Following the flow will help you pinpoint blockages or disruptions in the process, ensuring that repairs are done effectively.

Common Issues and Part Replacements

Over time, any system that involves moving parts or pumps may experience malfunctions. Identifying common issues early can help prevent more serious damage and ensure that the system continues to function effectively. By understanding what typically goes wrong and knowing the necessary replacements, you can resolve problems with minimal effort.

- Clogs and Blockages: Over time, waste materials can cause blockages in pipes or pumps. Regular cleaning and inspections can prevent these issues.

- Motor Failures: A malfunctioning motor is a common problem. Replacing the motor is essential when it fails to start or operates intermittently.

- Leaks: Leaks around seals or connections can reduce the system’s efficiency. Replacing worn-out seals is necessary to prevent further damage.

- Noisy Operation: Excessive noise can indicate worn-out components. Identifying and replacing damaged parts will restore normal operation.

Properly diagnosing the issue and replacing the faulty component can save time and money. Regular maintenance and familiarity with the components will help you quickly identify problems and take the right steps for repairs.