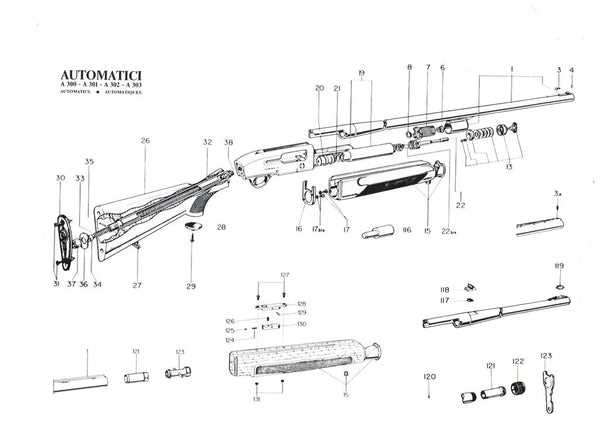

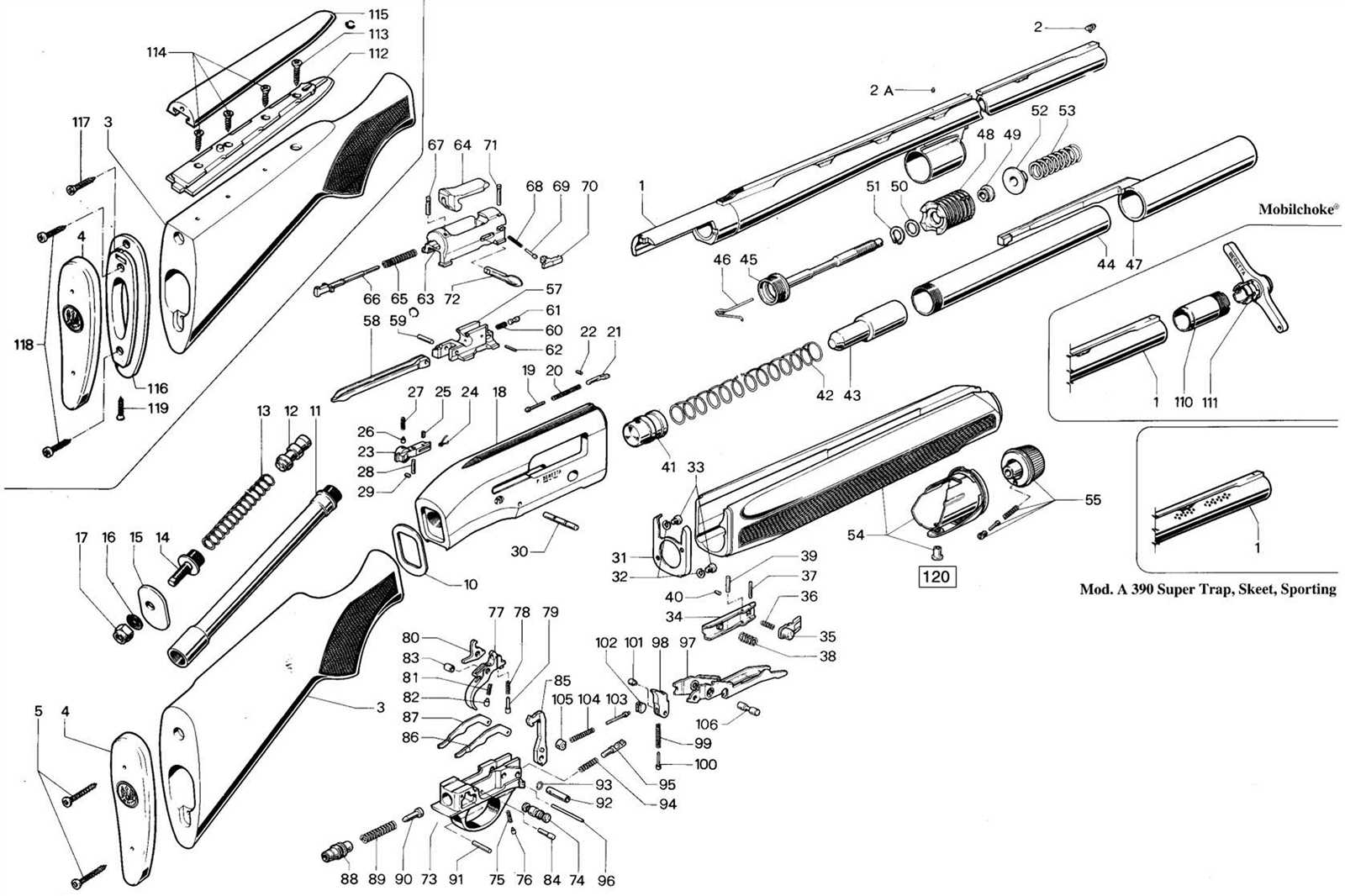

Maintaining your firearm in top condition is essential for its performance and longevity. Understanding its internal components and how they work together is the first step towards effective care. Whether you’re performing routine cleaning or tackling more complex repairs, a detailed visual reference of all the key elements can make a significant difference in the process.

Having access to an exploded view can help you identify and understand the function of each individual component. This not only aids in identifying any worn or damaged parts but also makes the assembly and disassembly process much simpler. Whether you’re a seasoned enthusiast or a novice, having a clear reference is invaluable for proper maintenance and troubleshooting.

Properly interpreting these visuals can save you time and frustration, ensuring that each part is handled with precision. With the right guidance, even the most intricate repair tasks become much more manageable.

Understanding Beretta 391 Parts Layout

Knowing how the individual components of a shotgun are arranged and interact with each other is crucial for proper maintenance and troubleshooting. A clear understanding of the layout helps users perform necessary tasks like cleaning, repair, and assembly with greater accuracy and efficiency. By breaking down the various sections, it becomes easier to identify and address specific issues that may arise during use.

Key Elements of the Shotgun’s Internal System

The internal system of any firearm consists of a series of interconnected parts that work together to deliver consistent performance. From the trigger mechanism to the gas system, each component plays an important role in ensuring the smooth operation of the gun. Familiarity with how these elements are positioned and how they function will make it easier to diagnose malfunctions and determine the need for replacements or adjustments.

Benefits of Understanding Component Layouts

Being able to visualize the structure of the gun provides a significant advantage when performing maintenance tasks. Not only does it improve efficiency, but it also minimizes the risk of misalignment or damage during reassembly. Understanding the arrangement ensures that each part is installed correctly, enhancing the overall reliability and longevity of the firearm.

Key Components of the Beretta 391 Shotgun

Understanding the core elements that make up any firearm is essential for proper maintenance and troubleshooting. Each individual component serves a distinct function, contributing to the overall efficiency and reliability of the gun. Identifying these parts and knowing their role helps users take better care of their equipment and ensures it operates at its peak performance.

Gas System: One of the most crucial systems in a semi-automatic shotgun is the gas operation. This mechanism harnesses the energy from the fired shell to cycle the action and load the next round. A well-maintained gas system ensures smooth cycling and prevents malfunctions.

Action Bars: These bars are essential in connecting the trigger group to the bolt assembly. They help transfer the necessary motion to operate the firing mechanism, allowing for consistent cycling of shells through the chamber. Their alignment and condition are vital for the gun’s proper functioning.

Firing Mechanism: This part includes the trigger, hammer, and sear assembly. It is responsible for igniting the primer of the shell when the trigger is pulled. A well-functioning firing mechanism guarantees reliable shot placement and minimizes the risk of misfires.

Extractor and Ejector: These components work together to remove spent shells from the chamber and eject them from the firearm. Ensuring they are in proper working order is essential for smooth operation, preventing jams and facilitating quick follow-up shots.

How to Use the Beretta 391 Diagram for Repairs

Having a clear visual representation of a firearm’s internal structure is invaluable when performing repairs. It allows you to identify individual components, understand their connections, and pinpoint the source of any issues. Whether you are dealing with a malfunction or conducting a routine overhaul, knowing how to use these reference materials effectively can save both time and effort.

Step-by-Step Guidance: Begin by locating the specific section of the diagram that corresponds to the part you are working on. Break down the repair process into manageable steps, starting with disassembling the components in the correct order. This will help avoid confusion and minimize the risk of damaging any parts during the process.

Identifying Faulty Components: Once you have identified the components in need of attention, the diagram can help you assess their condition. Pay close attention to areas where wear and tear are most likely to occur. Look for signs of cracks, misalignment, or accumulated debris that could affect performance. Having a detailed view ensures that no part is overlooked.

Reassembly Tips: After replacing or fixing the necessary parts, use the visual reference to reassemble the firearm correctly. Ensure that each part is placed in the proper position to avoid any misalignment that could affect the operation. Double-check all connections before reassembling the final components to ensure everything is securely fitted.