In modern vehicles, the intricate system responsible for smooth gear shifting plays a vital role in overall performance and efficiency. This complex mechanism is composed of several interconnected elements that work together to ensure seamless transitions between speeds. Understanding how each component functions can significantly enhance your knowledge of automotive engineering.

From the core rotational system to the smaller yet crucial control mechanisms, each part contributes to a well-orchestrated process. Without a clear understanding of these individual functions, diagnosing issues or performing maintenance can become a challenging task. By exploring the relationships between these elements, you gain insight into the system’s functionality and longevity.

In this article, we will explore the essential components of this vital system, detailing their functions and how they contribute to the vehicle’s overall performance. Whether you’re a mechanic or an enthusiast, understanding these key elements will provide a deeper appreciation for the technology that powers modern automobiles.

Understanding Automatic Transmission Components

In modern vehicles, the system responsible for shifting gears automatically relies on a series of interconnected elements. These components function together to provide smooth and efficient changes in speed, contributing to the vehicle’s overall performance. Knowing the role of each element is crucial for anyone involved in vehicle maintenance or repair.

Key Elements in the Gear-Shifting Mechanism

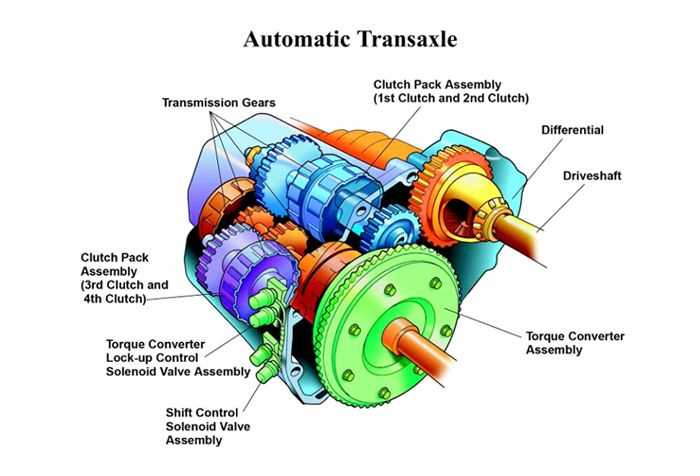

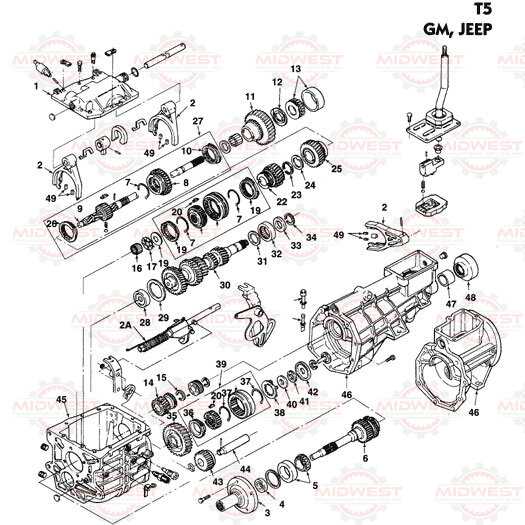

The core of the system consists of a series of gears and clutches that engage and disengage in response to the vehicle’s speed and driving conditions. The gearset is responsible for selecting the appropriate speed, while the clutch packs control the connection between gears. Each of these components must work together precisely to allow for smooth acceleration and deceleration.

Control Systems and Hydraulic Influence

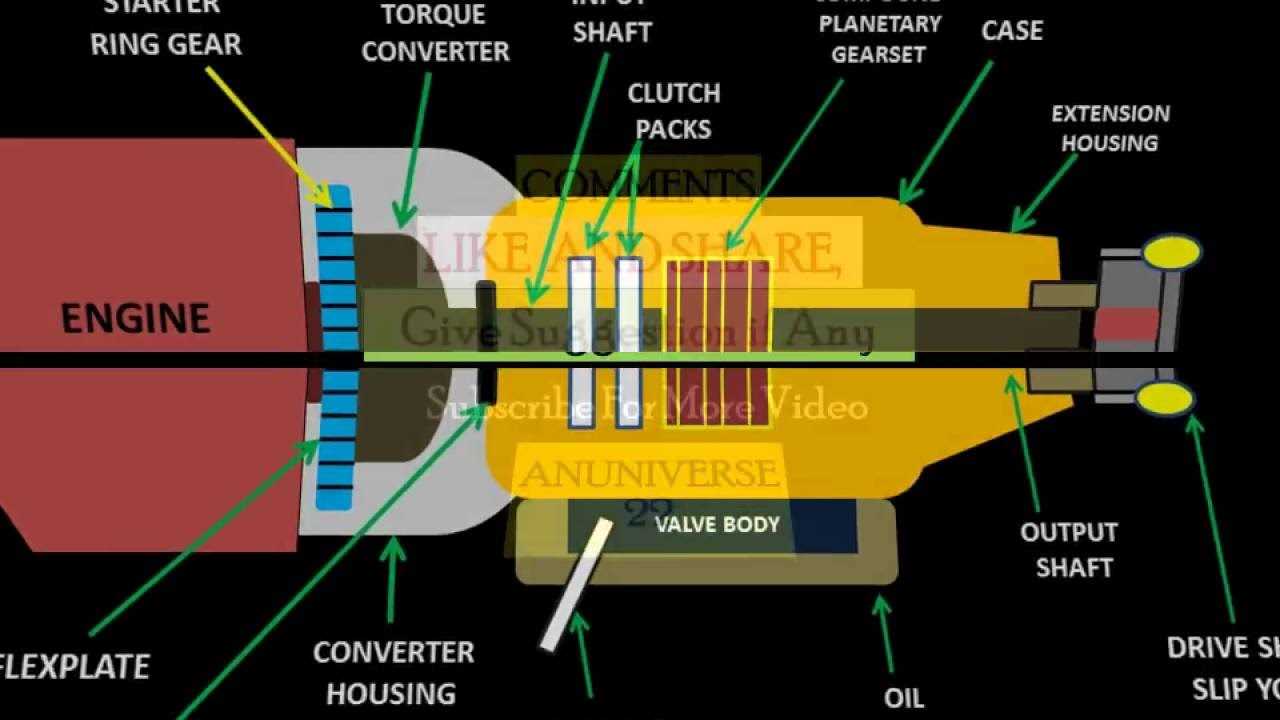

Control mechanisms play a vital role in managing the operation of the system. These include sensors and hydraulic systems that monitor factors like engine speed and torque. By adjusting the pressure and flow of fluid, the hydraulic system ensures the timely engagement of clutches and gearsets. This precise coordination ensures that shifts are made at the right moment for optimal performance.

Key Parts of an Automatic Transmission System

Every vehicle’s gear-shifting mechanism relies on several fundamental elements that control speed changes without manual input. These key components ensure that the vehicle accelerates smoothly, decelerates when needed, and adapts to various driving conditions. A breakdown or malfunction in any of these parts can significantly affect performance and drivability.

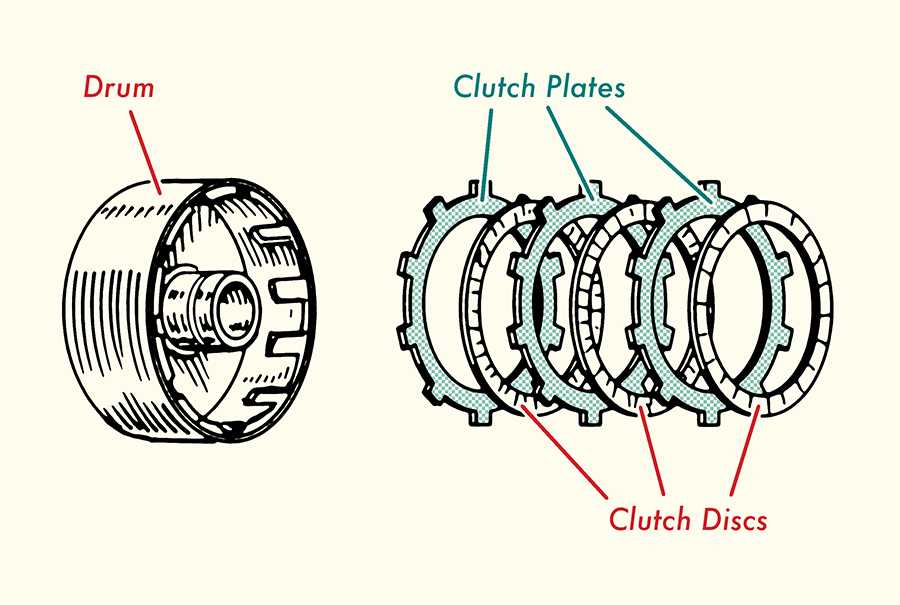

Clutch Packs and Gearsets

The clutch packs are responsible for engaging and disengaging the different gears in the system. They allow for smooth transitions between various speed ratios, providing the necessary torque for each driving condition. The gearsets, in turn, manage the different ratios, determining the engine’s output and ensuring the correct power is sent to the wheels at all times.

Hydraulic Systems and Sensors

Hydraulic systems play a critical role in controlling the pressure required for activating the clutch and gear mechanisms. These systems rely on sensors to monitor engine speed, vehicle movement, and torque levels. Based on this data, the hydraulic unit adjusts the flow of fluid to ensure that shifts occur at optimal moments, contributing to a seamless driving experience.

How Transmission Parts Work Together Efficiently

The seamless operation of a vehicle’s gear-shifting system depends on the precise coordination of various components. Each element has a specific function, but it is their interaction that ensures smooth performance. Without proper synchronization, shifting gears could become jerky or delayed, affecting both vehicle efficiency and driver experience.

Coordinated Engagement of Clutches and Gears

The clutches and gears are at the heart of this coordination. As the vehicle accelerates or decelerates, the clutches engage or disengage to select the appropriate gear. When these components work in harmony, the system can deliver the necessary power to the wheels without interruption. This smooth interaction ensures consistent performance and minimizes wear on the components.

Fluid Control and Sensor Integration

The hydraulic system, aided by sensors, ensures that fluid pressure is applied precisely at the right moments. Sensors monitor the vehicle’s speed and engine conditions, sending real-time data to the control unit. This allows the system to adjust the hydraulic flow, enabling timely engagement of clutches and gearsets. As a result, gear shifts occur seamlessly, enhancing both fuel efficiency and driving comfort.