Proper maintenance and understanding of snow removal equipment are essential for efficient operation and long-term performance. Each system consists of several key components that work together to ensure smooth functioning during winter conditions. Knowing the roles and positions of these elements is crucial for any operator.

In this section, we explore the essential elements of a snow removal system, highlighting their function, interconnectivity, and importance. By familiarizing yourself with these components, you can better diagnose issues, perform necessary repairs, and optimize overall performance.

Understanding the Snow Removal Equipment Components

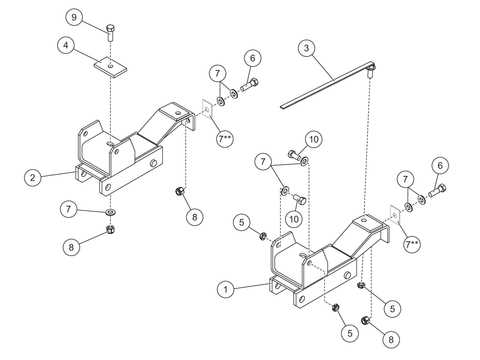

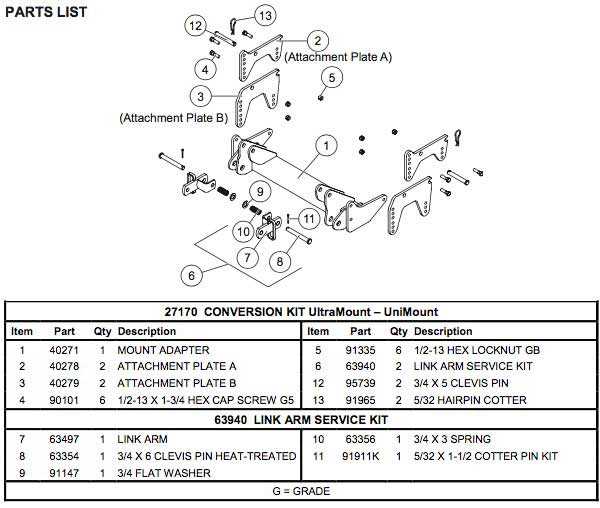

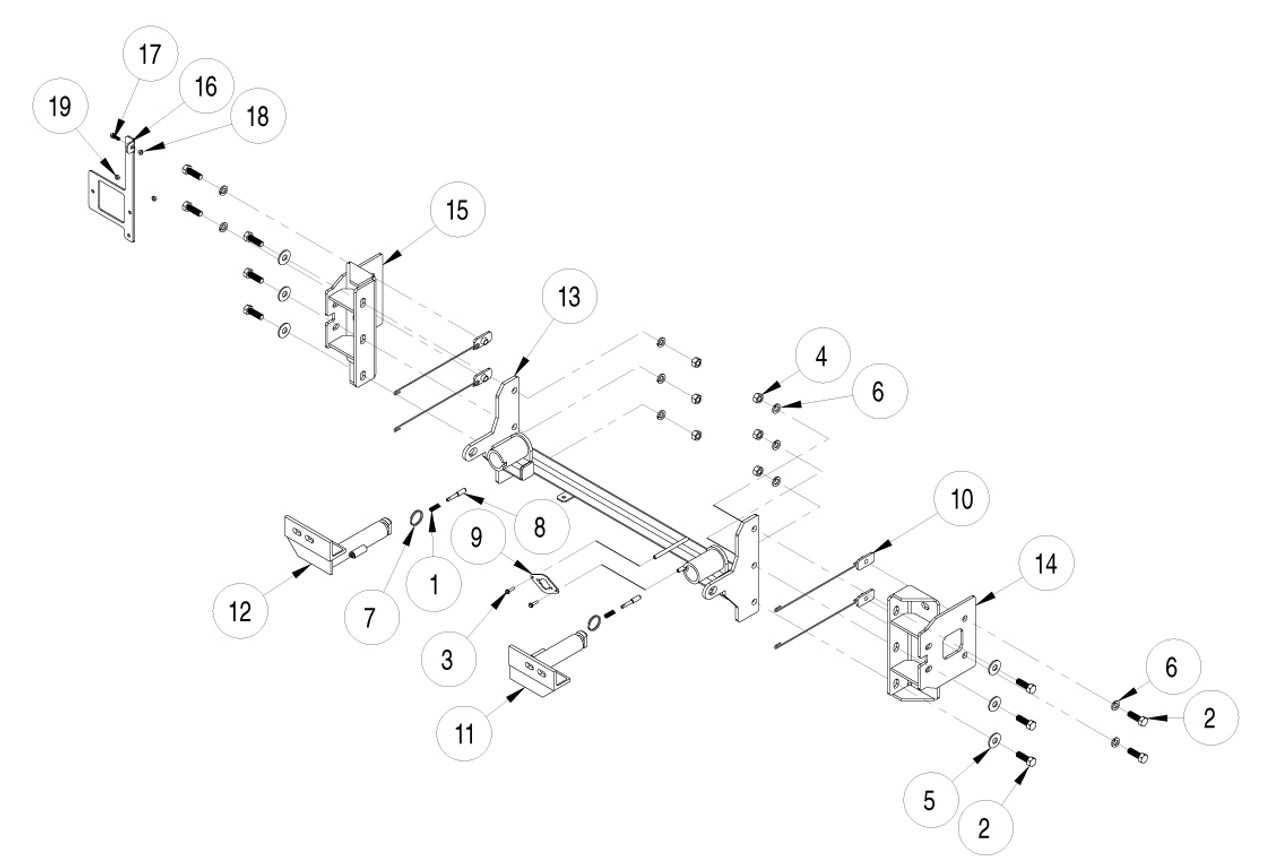

Snow clearing systems consist of various integral components that work together to ensure efficiency and reliability during winter operations. Each element plays a specific role, and understanding their functions is key to maintaining optimal performance. The proper functioning of the entire system depends on how well these components interact with each other.

Key features include the mechanisms that control movement, stability, and power distribution. By gaining insight into the structure and positioning of these components, operators can better manage maintenance, troubleshoot issues, and extend the life of their equipment.

Key Parts for Effective Snow Removal Operation

For any snow clearing system to operate smoothly, certain critical components must function correctly. These essential elements ensure that the equipment performs at its best, even under the most demanding conditions. Understanding their roles and how they contribute to the system’s overall performance is vital for effective operation and long-term durability.

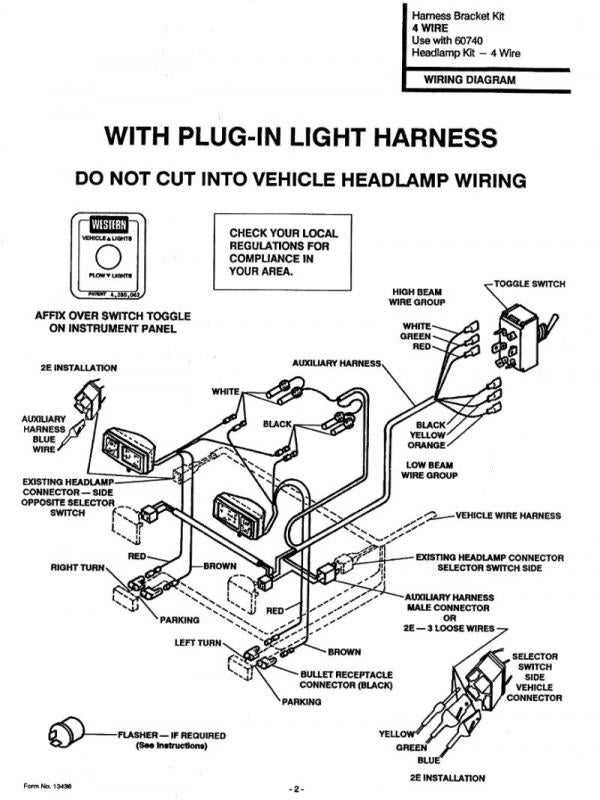

Control Mechanisms

Control systems are responsible for managing the movement and functionality of the equipment. They include levers, switches, and hydraulic systems that enable precise adjustments. Ensuring these controls are in good condition is crucial for responding to changing conditions and maintaining efficiency during operations.

Power Distribution Systems

The power distribution components transfer energy from the engine to the various parts that require it. This includes motors, pumps, and electrical systems that enable the equipment to function reliably. Regular checks and maintenance are necessary to keep these systems running smoothly and prevent unexpected failures.

Maintenance Tips for Snow Removal Equipment Components

Proper care and regular maintenance are essential to ensure the longevity and efficiency of snow clearing systems. By taking proactive steps to maintain key components, operators can prevent wear and tear, avoid costly repairs, and improve the system’s performance during harsh weather conditions.

Regular Inspections

Frequent inspections are necessary to detect potential issues before they escalate. Checking the structural integrity of key components, such as control systems and hydraulic lines, can help identify wear points early. Additionally, ensure that all moving parts are lubricated and free of debris to prevent unnecessary strain.

Cleaning and Storage Practices

Cleaning the equipment after every use helps remove salt, dirt, and ice buildup that can cause corrosion. Storing the equipment in a dry, sheltered area when not in use will also protect sensitive parts from environmental damage, ensuring that all systems remain functional when needed most.