When working on any machine, understanding its individual elements is essential for effective maintenance and repair. A clear visual representation can significantly ease the process, enabling users to identify, troubleshoot, and replace parts with precision.

In this section, we will explore how to interpret detailed component charts. Knowing the structure and function of each element allows for a more informed approach, whether you are carrying out routine checks or addressing specific issues. A comprehensive breakdown of these components will help you achieve optimal performance and longevity from your equipment.

Familiarity with the layout and connections of each part can save time and reduce errors. By examining the various pieces closely, you can make more accurate decisions and ensure that the assembly remains in top condition.

Understanding Key Components

To properly maintain or repair any equipment, it’s important to understand the structure of its individual components. Each element plays a crucial role in ensuring the smooth operation of the machine. By recognizing the purpose of each part and how they interact, users can address issues more effectively and prevent further damage.

Comprehending the relationships between components is essential for both troubleshooting and performance optimization. This knowledge enables you to identify the right pieces to replace or adjust, ensuring the longevity and efficiency of the system. The layout and connection points between parts should be carefully examined to avoid confusion during reassembly or upgrades.

Once you familiarize yourself with these essential pieces, you’ll be better equipped to handle maintenance tasks with confidence. Accurate identification and proper handling are key to maximizing performance and minimizing unnecessary repairs.

How to Read the Components Layout

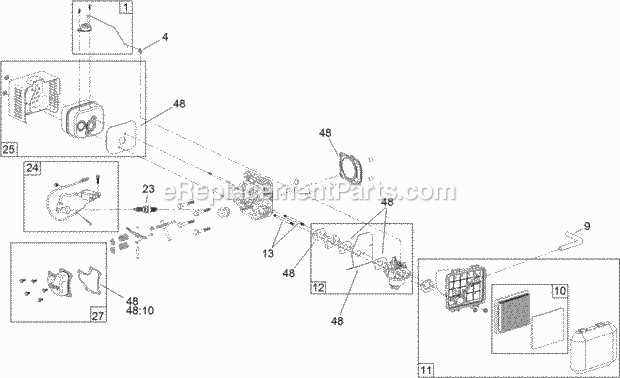

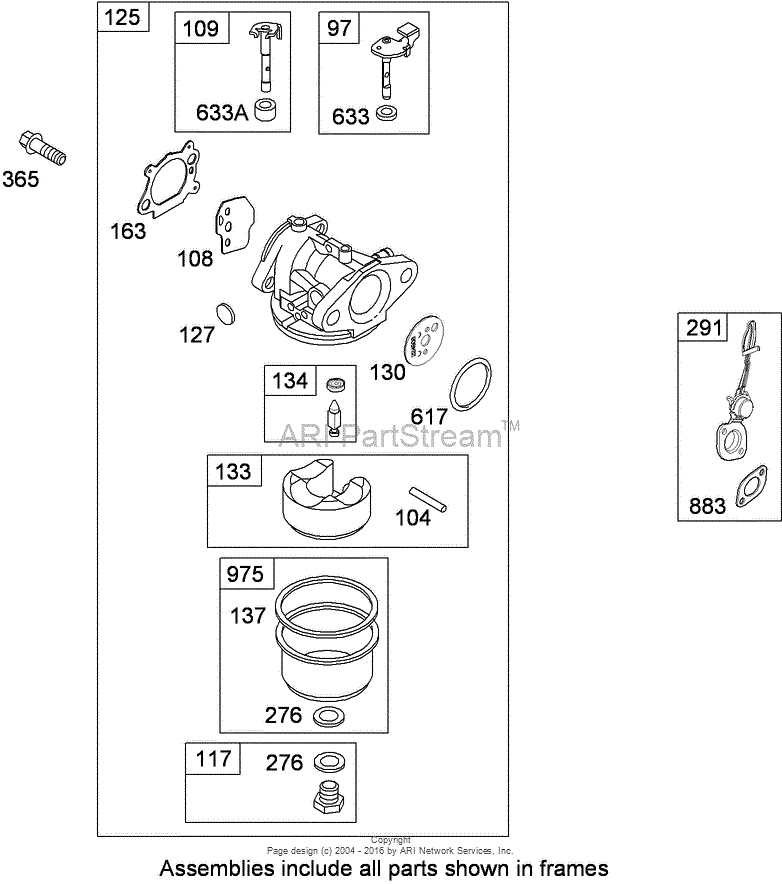

Understanding how to interpret a detailed layout of machine elements is crucial for anyone looking to perform maintenance or repairs. These charts serve as a guide, helping you identify each part’s location and its relation to other components. They allow for quick recognition of which areas need attention and assist in accurate reassembly.

Start by familiarizing yourself with the general structure and symbols used in these layouts. Each part is represented with a specific number and code, which corresponds to a list of descriptions. This reference list will provide details such as part names, sizes, and material specifications, making it easier to source replacements or troubleshoot issues effectively.

Once you understand the key symbols and references, it becomes easier to navigate the chart and pinpoint exactly what you need. The layout is designed to break down complex systems into manageable, understandable sections, ensuring you can follow the steps without confusion.

Essential Components of the Equipment

Every machine consists of key elements that contribute to its functionality and efficiency. These vital components are designed to work in harmony, ensuring that the system operates smoothly and reliably. Understanding each piece’s role is essential for effective troubleshooting and maintenance.

Critical parts such as the engine assembly, transmission system, and power controls form the backbone of the equipment’s performance. Each of these elements requires proper care and attention to maintain optimal functionality. Regular checks and timely replacements of worn-out pieces are crucial to avoid potential breakdowns and ensure continuous operation.

Additional elements, such as electrical systems and control units, while less visible, are equally important. These components help regulate the machine’s performance and ensure its smooth operation under various conditions. Familiarizing yourself with these essential parts will allow for more informed decisions when servicing the equipment.