Proper maintenance of your agricultural machinery is crucial for ensuring long-term performance and minimizing unexpected repairs. One of the key aspects of upkeep is knowing the individual components that make up the system, their functions, and how they interact with each other. Familiarity with these elements helps identify issues early and ensures smooth operation throughout the seasons.

In this guide, we will explore a detailed breakdown of the critical parts that make up your machine. With an easy-to-understand reference, you can recognize components quickly, check for wear, and determine when replacements are needed. Keeping track of these aspects can save both time and money on repairs.

Whether you are a seasoned professional or a new user, understanding the structure of your equipment will empower you to maintain it effectively. The following sections will provide insights into each major component, helping you stay on top of your maintenance schedule and keep your machinery running efficiently.

Understanding Bush Hog 3008 Components

Maintaining a piece of heavy machinery requires a solid understanding of its essential components. Each individual part contributes to the overall function and efficiency of the equipment. By learning the roles of these elements, you can more easily troubleshoot problems and perform necessary maintenance tasks. A clear understanding of the system’s structure ensures that each part is properly cared for, extending the machine’s lifespan and enhancing its performance.

The key components of the system are designed to work together seamlessly. From the cutting mechanism to the drive assembly, each part is engineered for a specific function. Knowing how these pieces interact and where they are located allows you to handle repairs and replacements more effectively. Whether it’s the hydraulics or the gearing, each part plays a vital role in ensuring the machine operates as intended.

Familiarizing yourself with the individual components also helps in identifying wear and tear before it leads to bigger issues. Regular inspection of critical elements allows you to replace parts before they fail, keeping downtime to a minimum. With this knowledge, you can ensure your equipment remains reliable and performs at its best, no matter the task at hand.

How to Identify Bush Hog 3008 Parts

Identifying the components of your machinery is crucial for effective maintenance and repairs. When you’re familiar with the key elements of your equipment, you can quickly recognize any signs of damage or wear. Knowing where each part is located and what it does helps streamline the process of diagnosing problems and making replacements.

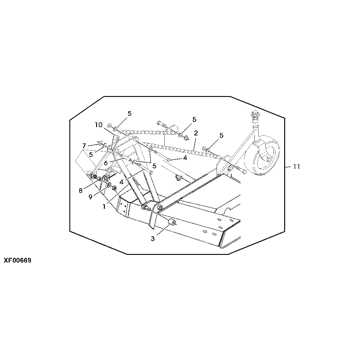

To effectively identify the various components, start by understanding the general layout and function of the system. Once you have an overview, look for specific features and characteristics that distinguish each element. Pay attention to the following tips:

- Consult the user manual: The manual typically provides diagrams or detailed descriptions of each part, helping you understand their locations and functions.

- Use visual cues: Many components have unique shapes, sizes, and markings that make them easy to identify. Look for labels or stamped numbers that can provide additional information.

- Check for wear patterns: Certain parts will show wear signs differently, such as cracks, rust, or discoloration. Familiarize yourself with common signs of damage for each component.

- Look at the assembly: Components are often grouped based on function, so understanding the overall assembly can help you narrow down where each part fits.

By following these steps, you can quickly recognize and identify the necessary components of your machine. This knowledge will make maintenance easier and help prevent potential breakdowns.

Common Issues and Parts Replacement Tips

Even with regular maintenance, machinery can experience issues that require attention. Recognizing common problems early and understanding when to replace specific components is essential to keeping your equipment running smoothly. By being proactive in identifying wear and tear, you can prevent costly breakdowns and extend the life of your equipment.

Frequent Mechanical Failures

One of the most common problems involves wear on moving parts such as gears, belts, and blades. Over time, these elements can become loose, worn out, or damaged, leading to decreased performance or even complete failure. To avoid this, it is important to regularly inspect and replace any worn components.

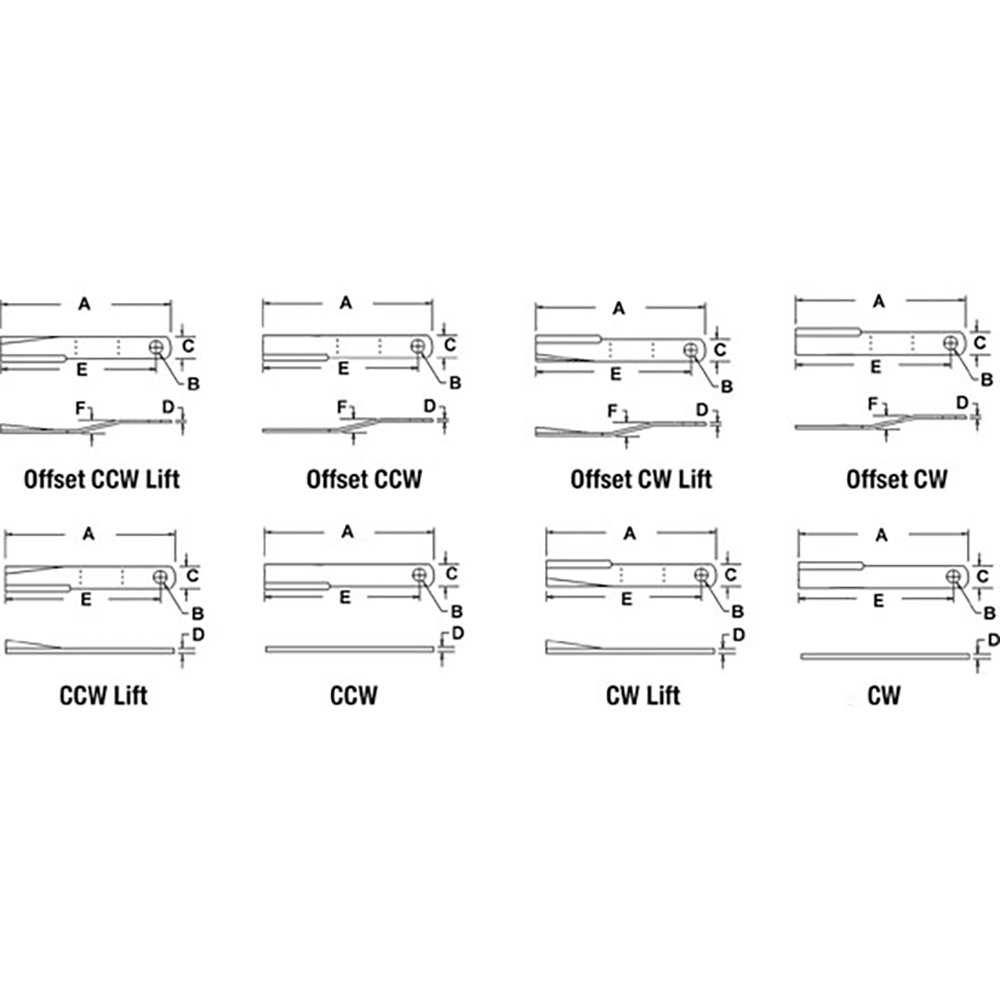

- Blades: Dull or chipped blades can cause uneven cuts and excessive strain on the engine. Replace them when they show signs of damage or wear.

- Belts: Worn-out belts can slip or break, leading to power loss. Check them for cracks or stretching and replace them as needed.

- Bearings: Faulty bearings can create excessive noise and vibrations, which may signal the need for replacement.

Hydraulic and Structural Issues

Hydraulic systems are often the backbone of large equipment, and issues such as leaks or loss of pressure can affect performance. Leaking hoses, faulty cylinders, or low fluid levels can cause the system to malfunction. Additionally, structural damage to frames or supports should not be ignored, as it can lead to more serious breakdowns if left unchecked.

- Hydraulic Hoses: Inspect for cracks or signs of wear and replace hoses if necessary to prevent leaks.

- Fluid Levels: Keep an eye on hydraulic fluid levels, ensuring they remain within the recommended range to prevent pressure loss.

- Frame Integrity: Regularly check the frame and supports for cracks or signs of damage and replace any compromised parts.

By staying vigilant and addressing these common issues early, you can ensure the continued efficiency and reliability of your machine. Regular replacement of key components will prevent larger issues and help maintain optimal performance for years to come.