In any mechanical lifting system, understanding the key components is crucial for effective maintenance and smooth operation. A thorough knowledge of how each part interacts ensures that the system performs at its best and minimizes potential issues. The components of these systems work together to provide stability, control, and safety during use.

Properly identifying and understanding the function of each piece is the first step in addressing malfunctions or performing routine checks. It allows for quicker repairs and the prevention of further damage, ultimately extending the life of the equipment.

By familiarizing yourself with the structure and mechanisms involved, you will gain confidence in troubleshooting, replacing parts, or simply performing regular upkeep. A clear visual representation of these components can help clarify the assembly and provide valuable insight into how the system works.

Understanding Key Components of a Lifting Mechanism

Every lifting mechanism is built from several essential components that work together to ensure functionality and reliability. These elements are designed to provide stability and control, enabling the system to handle various loads safely. By understanding each part’s role, users can improve maintenance, identify issues, and make informed decisions when repairs or replacements are needed.

At the core of any such system, you’ll find moving parts that are responsible for the lifting action, along with structural elements that provide support and prevent unwanted movement. Components like the support base, gearing system, and locking mechanism all play a critical role in ensuring smooth operation. Knowing how these parts interact can help users identify weak points that may require attention.

Regular inspection and understanding of these components ensure that the lifting system continues to perform at its optimal level. By familiarizing yourself with each element, users can troubleshoot more effectively and prevent unnecessary wear or malfunction in the long run.

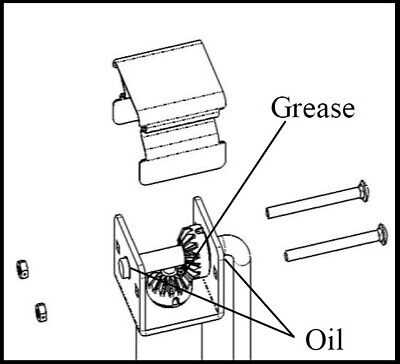

How to Read a Lifting Mechanism Blueprint

Interpreting a blueprint for any mechanical system requires understanding the symbols and labels that represent its individual components. These blueprints serve as a visual map, providing a clear overview of how each part fits together and functions within the larger structure. By familiarizing yourself with the layout, you can quickly identify the parts and their connections, ensuring proper maintenance and troubleshooting.

The blueprint typically uses simple drawings, each one corresponding to a specific element of the system. Each part is clearly marked, often with labels or numbers, which can be cross-referenced with a parts list for further detail. By following these connections and identifying the relationships between parts, users can gain a deeper understanding of how the mechanism operates as a whole.

Once familiar with the basic symbols and layout, the next step is to study the flow of movement and mechanical interactions. Understanding the function of each element in the context of the system allows users to make informed decisions about repairs or upgrades. With practice, interpreting these blueprints becomes easier and can help ensure the longevity and efficiency of the equipment.

Common Issues with Lifting System Components

Even the most well-designed mechanical systems can experience issues over time, and understanding these potential problems is crucial for effective maintenance. Common issues often stem from wear and tear, lack of lubrication, or improper use, all of which can compromise the system’s performance. Identifying these problems early can help prevent more serious damage and ensure the mechanism remains operational for longer periods.

Worn or Damaged Gears

One of the most frequent problems is the wear of gears, which are vital for the lifting mechanism’s movement. Over time, gears can become worn down, causing them to slip or fail entirely. This can lead to uneven lifting or a complete loss of function. Regular inspection and timely replacement of these components can prevent further complications.

Leaking Seals and Lubrication Issues

Another common issue is the failure of seals, which protect internal components from dirt and moisture. When these seals break or degrade, it can lead to fluid leaks or contamination, which affects the smooth operation of the system. Regularly checking and replacing seals, along with ensuring proper lubrication, can keep the system running smoothly and prevent premature failure of other components.