Maintaining and repairing your chainsaw can be a daunting task without a clear understanding of its internal structure. To effectively troubleshoot or replace worn-out components, it’s crucial to have access to a clear visual representation of the machine’s key elements. This guide will help you navigate through the essential parts of your tool, providing insight into their functions and how to identify them quickly.

By examining the detailed layout of each piece, you’ll gain a better understanding of how the engine, handles, and other essential components fit together. Whether you are a seasoned technician or a DIY enthusiast, knowing where to find and how to replace faulty components will save both time and effort in the long run.

In this article, we’ll explore the most common parts, how they contribute to the overall performance, and tips on replacing them with ease. Knowing your equipment inside and out will ensure smoother operation and help extend its lifespan.

Understanding Chainsaw Components

When it comes to maintaining or repairing a chainsaw, having a clear grasp of its various elements is essential. Each section plays a vital role in the overall functionality of the machine, from the engine to the cutting mechanism. Recognizing and understanding these components allows you to address issues effectively and ensure the tool operates at its best.

The engine housing, the carburetor, and the fuel system all work together to power the saw. Meanwhile, the cutting assembly, including the bar and chain, is directly responsible for the tool’s primary task. Understanding how these parts interconnect will help in diagnosing problems, whether it’s an issue with fuel delivery, the engine’s performance, or wear and tear on the cutting components.

By familiarizing yourself with the function of each section, you can perform maintenance tasks such as cleaning, lubrication, and replacement with ease. Additionally, knowing which elements are prone to wear will help you anticipate necessary repairs before they affect the chainsaw’s performance.

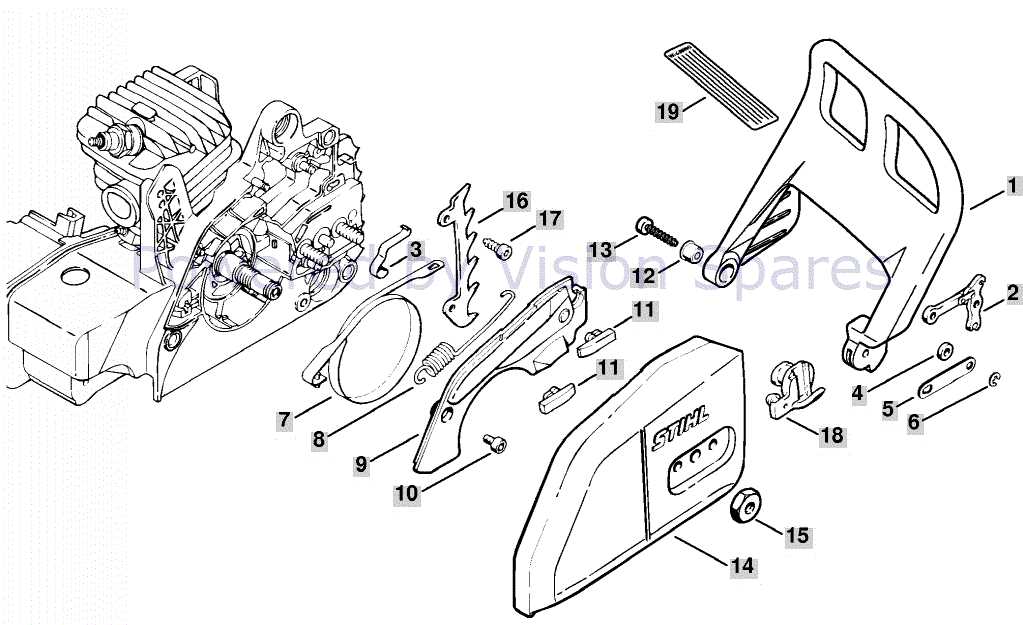

How to Read the Visual Layout

Interpreting a visual breakdown of a machine’s components is an essential skill for anyone involved in maintenance or repairs. Such a layout typically provides a clear, organized view of the tool’s major sections, allowing you to easily identify and locate each part. Understanding how to navigate this diagram can save you time when troubleshooting or replacing worn-out components.

Each element is usually labeled with a unique identifier, often accompanied by a reference number or code. These identifiers correspond to a list of descriptions that explain the function or name of each item. It’s important to familiarize yourself with the key so you can match the visual cues with the correct component descriptions, enabling you to pinpoint issues quickly.

By studying the layout, you’ll also gain insight into the relationship between parts. Understanding how each component fits into the broader system of the tool is crucial when performing repairs or upgrades. This knowledge helps ensure the parts are correctly reassembled, preventing any potential operational issues.

Common Replacement Components

Over time, certain sections of a chainsaw experience wear and tear due to regular use. Some components are more prone to damage or degradation and will eventually need to be replaced to keep the machine functioning efficiently. Knowing which parts typically require replacement can help you maintain your equipment in peak condition and avoid unexpected breakdowns.

The cutting chain and guide bar are among the most frequently replaced items, as they directly interact with the material being cut. These components can become dull, bent, or damaged after prolonged use, impacting the performance of the tool. Additionally, the air filter often requires regular replacement to ensure proper airflow and engine function, as clogged filters can cause reduced power and fuel efficiency.

Other common replacements include spark plugs, fuel lines, and the carburetor, all of which play crucial roles in the tool’s overall operation. Regular inspection of these parts will help you identify when they are reaching the end of their lifespan, ensuring your chainsaw remains reliable and ready for use at any time.