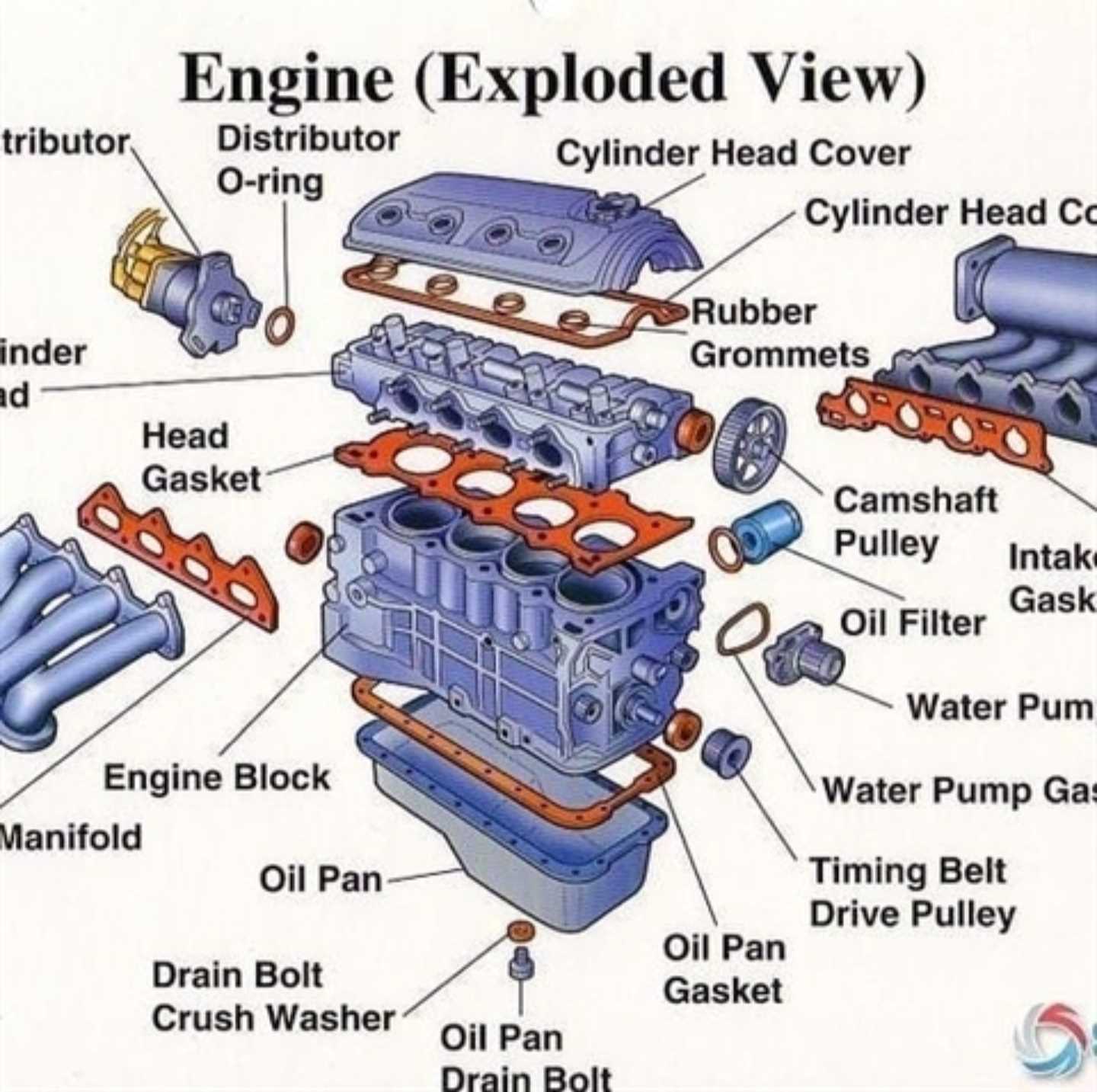

When it comes to the inner workings of any machine, especially those designed for heavy-duty tasks, a detailed breakdown of its internal mechanisms is essential. This section explores the intricate system of interconnected elements that power and drive the machinery forward.

Each part plays a vital role in ensuring smooth operation, from the core components responsible for generating power to the smaller yet crucial elements that contribute to efficiency. By comprehending the function of each piece, you can gain a deeper appreciation of how everything works in harmony.

As we examine this system, we’ll focus on its structure and how each segment interacts with others to ensure optimal performance. Understanding this layout not only aids in maintenance but also helps in troubleshooting issues when they arise, making it a valuable tool for any enthusiast or professional.

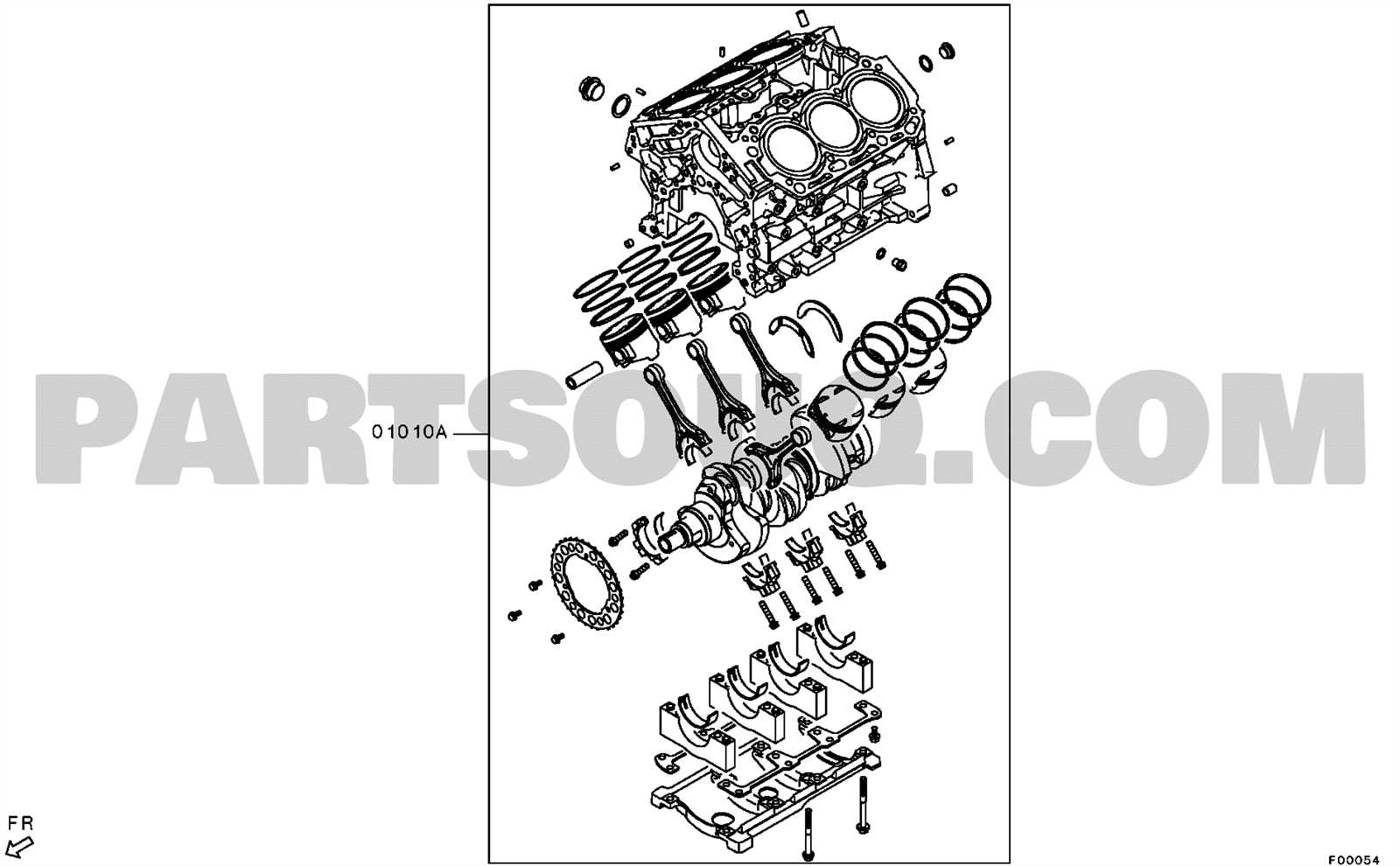

Understanding the Components of a 5.3 Engine

The heart of any powerful machine lies in its intricate assembly of mechanical elements, all working together to deliver the necessary force and efficiency. Every individual component has a unique function, contributing to the overall performance of the system. To fully comprehend how a vehicle operates, it’s essential to understand the roles and relationships between these elements.

Main Functional Units

At the core of this system are the larger, primary components responsible for generating the necessary force. These units work together to create the mechanical energy required to move the machine. They are supported by a network of smaller, yet equally important elements, which ensure smooth operation, control, and optimization of power.

Supporting Elements and Their Roles

The supporting components are integral to maintaining balance, temperature regulation, and fuel efficiency. From the various sensors to cooling mechanisms, these elements make sure that the primary units function under optimal conditions. Proper interaction between all components ensures the longevity and reliability of the entire system.

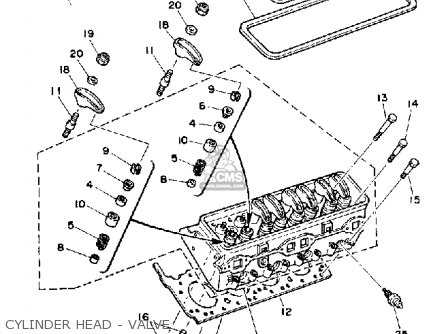

Key Parts and Their Functions Explained

In any complex system, understanding the core components is crucial to recognizing how they contribute to overall performance. Each vital element plays a specific role that ensures smooth operation, with certain parts being responsible for the creation of power, while others handle control, efficiency, and safety.

Power Generation Units

The primary components involved in generating power are fundamental to the system’s ability to perform its tasks. These units are responsible for converting fuel and energy into motion, which is the key to driving the machinery. Their optimal function is essential for maintaining the overall strength and efficiency of the system.

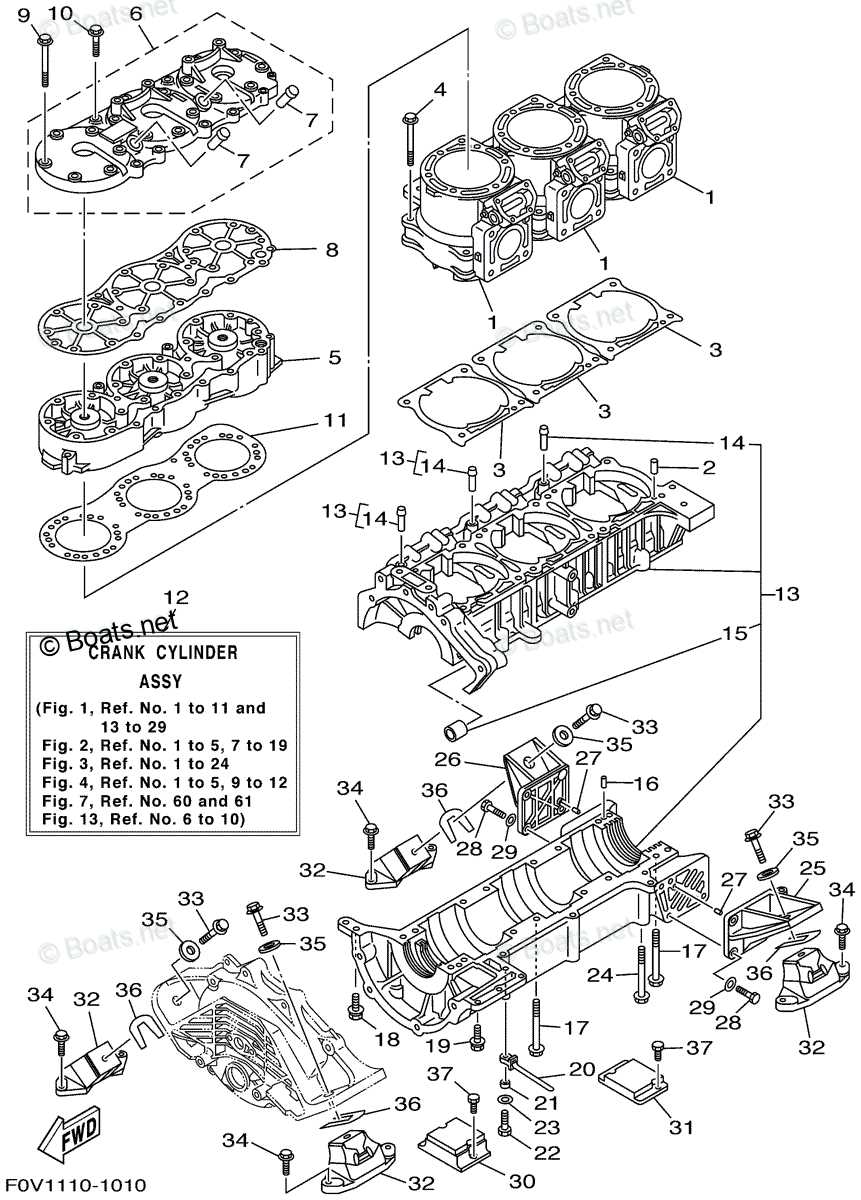

Support and Control Systems

Equally important are the smaller components that regulate temperature, manage fuel flow, and maintain balance throughout the system. These support elements ensure that everything operates under ideal conditions, preventing overheating, maximizing fuel usage, and ensuring consistent performance over time.

How the 5.3 Engine Works Together

The inner workings of any powerful machine rely on the seamless interaction between its various components. Each element, from the main power generation units to the supporting systems, has a specific role, and their synchronized function is essential for the system to operate efficiently. Understanding how these components work together is key to appreciating the complexity and reliability of the whole setup.

When the core components generate power, the auxiliary systems manage vital tasks such as temperature regulation, fuel distribution, and exhaust control. These smaller systems ensure that the power units perform at their best, maintaining balance and efficiency under different operating conditions. The perfect coordination between all these elements allows for smooth and consistent operation.