When it comes to maintaining and repairing lawn equipment, understanding the layout of individual components is crucial. A detailed breakdown of a machine’s inner workings not only helps with regular upkeep but also simplifies troubleshooting when issues arise. Knowing how each part fits together ensures that your equipment performs at its best, season after season.

Every machine has a unique structure, with each piece playing an essential role in its overall function. By familiarizing yourself with the arrangement and functions of these parts, you can make informed decisions about repairs, replacements, and upgrades. Proper knowledge can significantly extend the life of your machinery, reducing the need for professional services.

This guide offers insights into how to navigate through the essential components of your lawn tractor. Whether you’re tackling a minor fix or planning more extensive maintenance, this resource will provide the clarity needed for successful repairs. Understanding these details is the first step toward becoming more self-sufficient in lawn care equipment management.

Understanding Lawn Tractor Components

Every lawn tractor consists of a variety of interconnected elements, each serving a specific purpose in the overall functionality of the machine. The structure is designed to provide efficiency and durability, ensuring that all components work harmoniously to deliver optimal performance. Gaining a deeper understanding of these elements allows for better maintenance and troubleshooting.

The engine, transmission, and steering system are among the most critical parts of a tractor. These primary components ensure smooth operation, from power generation to direction control. Additionally, the frame and chassis offer the necessary support, allowing the tractor to handle heavy workloads without compromising stability.

Knowing how these components interact with one another is essential for anyone responsible for the care of such equipment. Familiarity with the key parts not only makes it easier to identify problems but also helps in determining which replacements or repairs may be needed over time. This insight into the machinery’s design provides confidence when making decisions about maintenance and repair tasks.

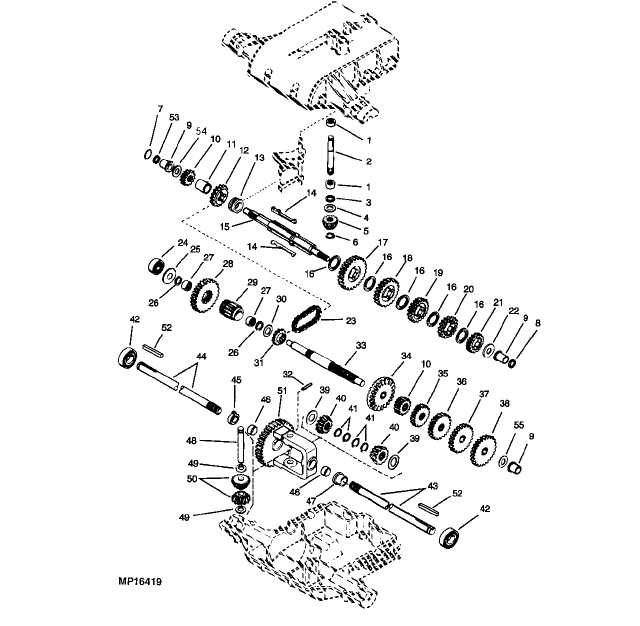

How to Read the Components Layout

Understanding how to interpret a machine’s component layout is essential for effective maintenance and repair. These layouts provide a visual guide, helping you identify each part and its function within the system. Knowing how to read these guides ensures that you can locate the necessary components quickly and accurately when performing repairs or replacements.

When viewing a layout, it’s important to focus on the following key aspects:

- Part labels: Each component is usually labeled with a number or name that corresponds to a list of descriptions or part numbers.

- Groupings: Parts are often grouped by their function, such as engine components, transmission, or electrical systems. This grouping helps to break down the complexity of the machinery.

- Connection points: Understanding how parts are connected is crucial, as it will guide you in safely disconnecting or replacing them.

By following these steps and understanding the layout’s symbols and references, you can navigate through the components efficiently. It allows you to troubleshoot issues, identify required replacements, and order the correct parts without confusion.

Common Repairs and Part Replacements

Over time, regular use of outdoor equipment leads to wear and tear on various components. Understanding which parts are most likely to need attention can help prevent unexpected breakdowns and ensure the machine continues to function properly. Some repairs are simple and can be done at home, while others may require professional expertise.

Engine maintenance is one of the most frequent areas requiring attention. Common issues include spark plug wear, air filter clogging, and fuel system problems. Replacing a clogged air filter or cleaning the carburetor can restore the engine’s efficiency and power output.

Transmission issues often arise when the equipment is subjected to heavy use. Common symptoms include difficulty in shifting gears or a grinding noise during operation. In such cases, inspecting the belts and pulleys, or replacing worn components, can resolve these issues and extend the life of the system.

Additionally, components such as wheel bearings and steering mechanisms are prone to wear, particularly in environments where the machine is frequently exposed to harsh conditions. Replacing these parts ensures smooth operation and prevents more serious damage to the equipment’s structure.