When maintaining or repairing a leaf blower, having a clear overview of its internal structure is crucial for efficient troubleshooting. Knowing the different elements and their functions allows for smoother repairs and ensures the longevity of the equipment. This understanding also helps when replacing worn-out parts or assembling the tool after disassembly.

Recognizing key parts of the machine and their role in its operation is the first step in ensuring that the blower functions optimally. Each component works together to provide the necessary airflow and power for effective yard work. Whether you’re dealing with fuel issues, engine trouble, or air intake blockages, understanding the overall design will save time and effort.

By familiarizing yourself with a detailed reference guide or schematic, you can easily pinpoint faulty areas and make informed decisions. This approach not only simplifies the repair process but also minimizes the risk of making mistakes that could lead to further damage. Whether you’re a professional or a DIY enthusiast, knowing your machine inside and out is essential for top performance.

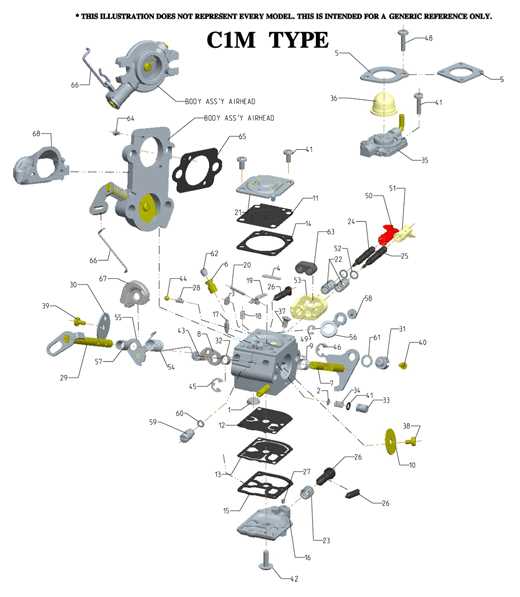

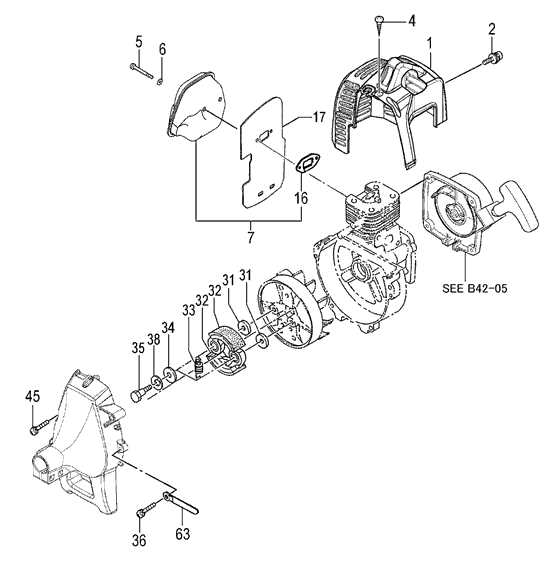

Understanding the Components Breakdown

Having a clear visual representation of the internal layout of your blower can significantly simplify maintenance and repair tasks. It provides an organized way to view all the essential elements, making it easier to identify each component’s location and function. By understanding the overall structure, you can effectively troubleshoot issues and perform necessary repairs with confidence.

A well-organized reference allows users to:

- Quickly identify damaged or worn-out elements

- Track the assembly process during reassembly

- Ensure all parts are correctly aligned and functioning

With this reference, it’s possible to spot minor problems before they become more serious, reducing repair costs and downtime. Whether you are repairing an engine or adjusting airflow systems, this guide acts as a helpful map for efficient maintenance. Understanding how the various components interconnect will give you the tools to extend the life of your blower while maintaining peak performance.

Key Components of the Leaf Blower Explained

Understanding the main elements that make up your blower can help you identify issues quickly and ensure optimal performance. Each part plays a specific role in delivering the desired power and efficiency. Familiarizing yourself with the crucial components can make troubleshooting much easier and faster, whether you’re performing a routine check or repairing a malfunction.

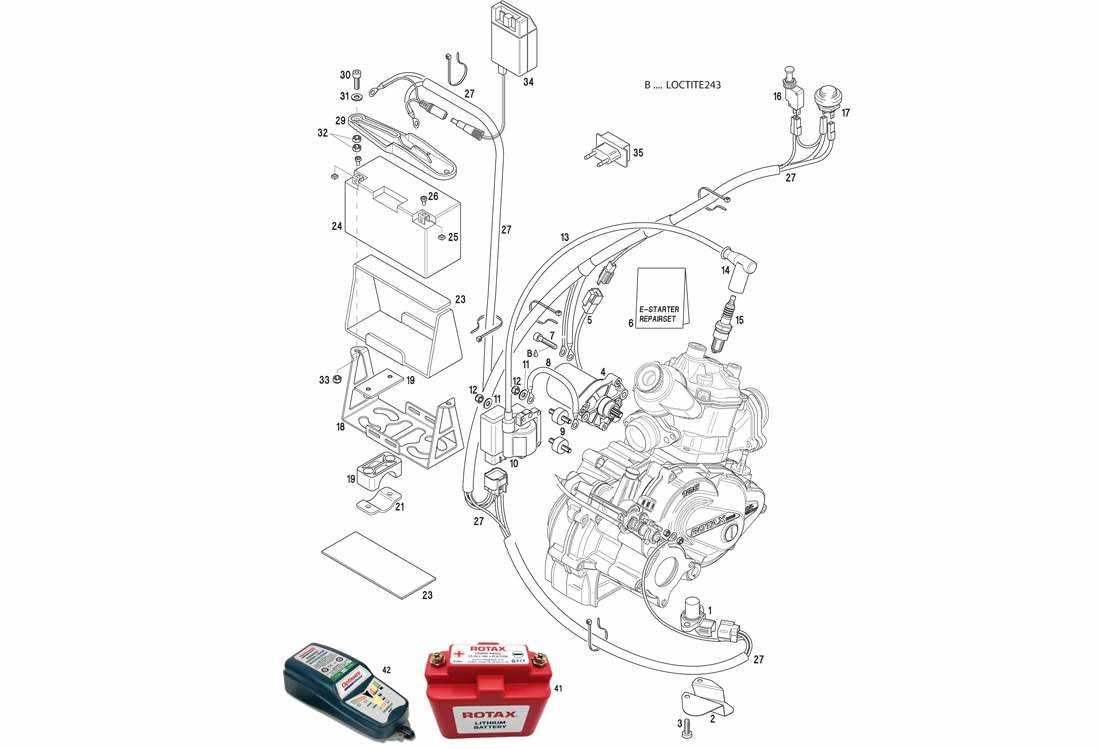

Engine and Power Mechanism

The engine serves as the heart of the blower, providing the necessary power to drive the fan and produce the high-speed air needed for efficient operation. It is typically a small, fuel-powered unit that includes vital parts like the spark plug, fuel lines, and carburetor. A well-maintained engine ensures smooth operation and reduces the chances of overheating or starting issues.

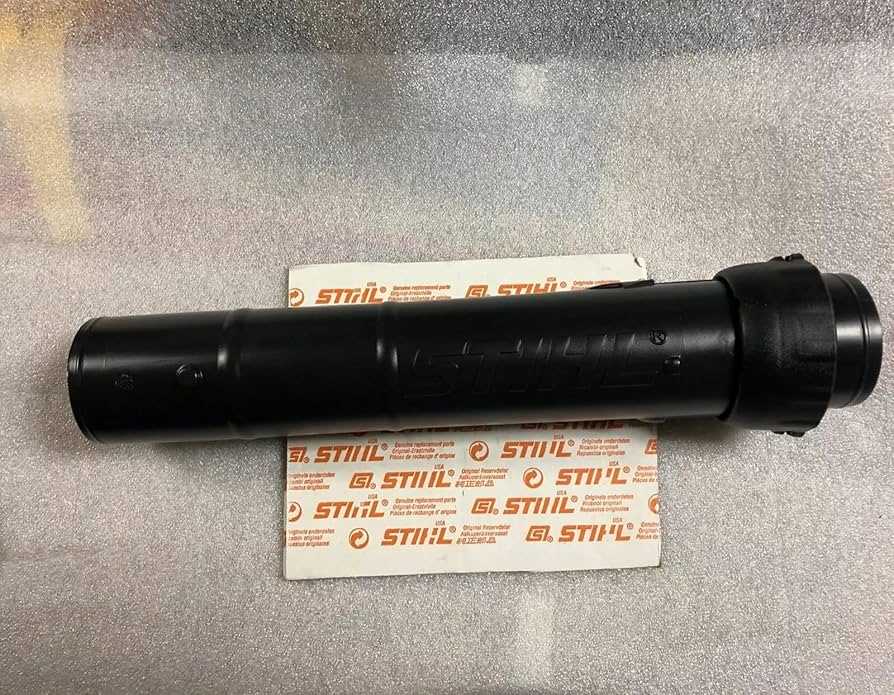

Airflow and Fan System

The fan and air intake system are essential for directing air at high velocity to clear debris. This part of the tool is responsible for generating the powerful wind force that makes the machine effective. Regular cleaning of the air filter and fan blades is crucial for maintaining strong airflow and preventing clogging, which can reduce performance.

How to Use the Schematic Effectively

Having a clear reference of your blower’s internal layout can greatly enhance the repair and maintenance process. An accurate schematic helps you identify each individual element and understand how they fit together, allowing for quicker diagnosis and easier assembly. Knowing how to interpret this visual guide is essential for ensuring that repairs are done correctly and efficiently.

Step-by-Step Troubleshooting

When an issue arises, you can use the schematic to pinpoint the malfunctioning component. By following the flow of the system, you can easily trace the problem to its source. This methodical approach helps save time and reduces unnecessary disassembly, making it simpler to focus on the exact part that needs attention.

Proper Assembly and Reassembly

After performing maintenance or replacing components, the schematic acts as a roadmap to ensure everything is put back in its rightful place. This ensures that no small parts are overlooked and that all connections are secure. Referencing the schematic helps you avoid mistakes, reducing the chances of improper reassembly that could lead to future complications.