When working with any power tool, knowing the layout and function of each component is essential for proper maintenance and efficient operation. A clear understanding of these parts can help users troubleshoot issues, perform repairs, and extend the tool’s lifespan.

Having a detailed reference guide that outlines the key components of your equipment simplifies the process of identifying damaged or worn-out pieces. By being familiar with the structure and functions of each section, users can address problems more confidently and avoid unnecessary breakdowns.

In this guide, we will explore the essential elements of your tool, breaking down its design to ensure you can easily navigate and understand how to keep it in optimal working condition. Whether you’re looking to replace a specific piece or simply want to learn more about its inner workings, this overview will be a valuable resource.

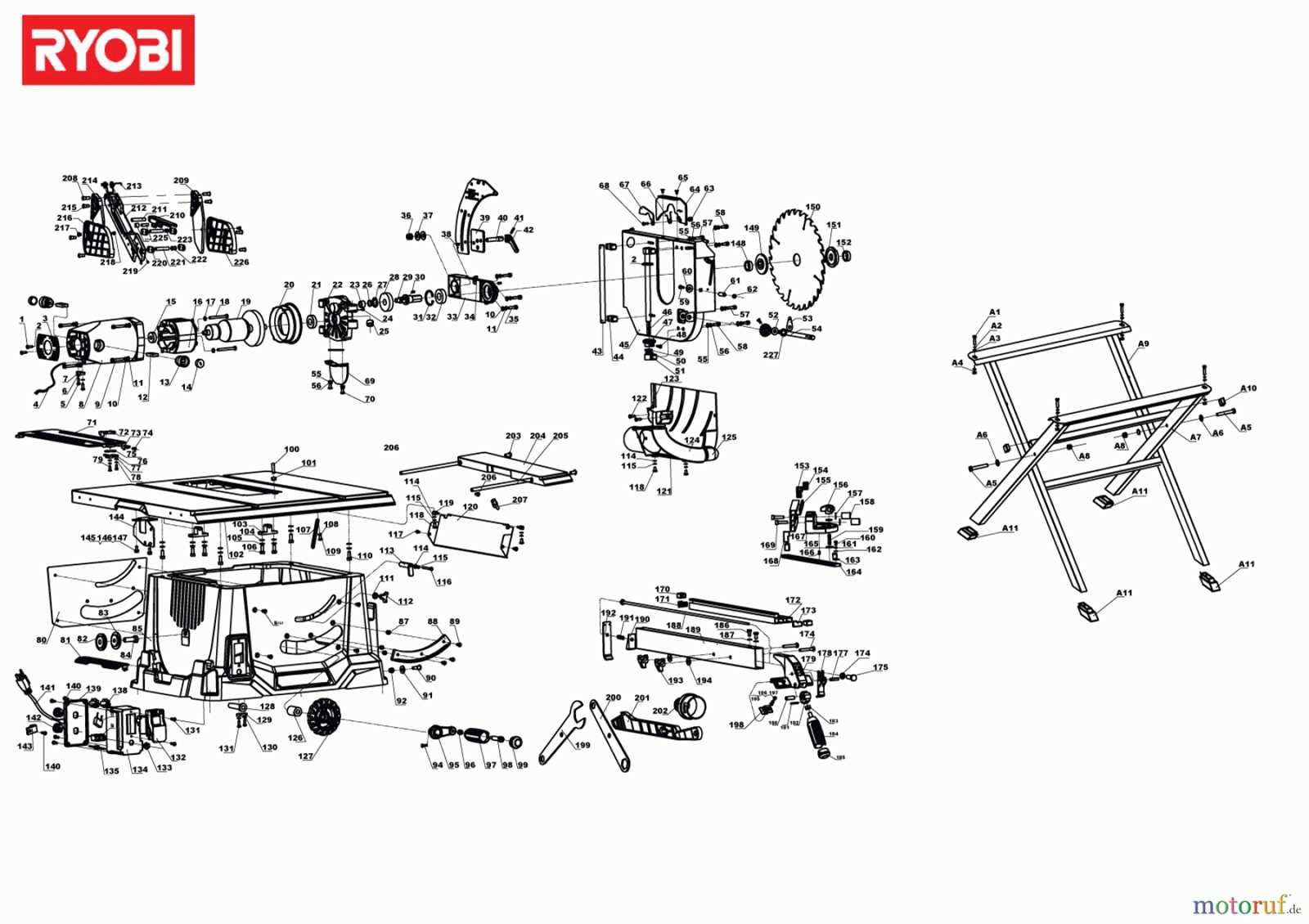

Understanding the Ryobi 10 Table Saw

To ensure proper functionality and maintenance of your woodworking equipment, it is crucial to understand how its various components interact. A well-designed machine consists of several integral pieces that work together to deliver the desired performance. Knowing the role each element plays in the overall system helps users make informed decisions when it comes to repairs or upgrades.

Key Features of the Equipment

This tool is built with precision and efficiency in mind, featuring robust parts that are designed to withstand heavy use. The power source, cutting mechanism, and control settings all contribute to the overall performance, and understanding their functions is essential for achieving accurate results. Familiarizing yourself with these features also helps when you need to identify areas that may require attention.

Maintenance and Troubleshooting

Regular maintenance is the key to prolonging the life of your tool. By knowing the structure and functionality of the different components, you can easily spot any issues and address them before they cause significant damage. Whether it’s cleaning, replacing worn parts, or making adjustments, having a solid understanding of the equipment ensures that it continues to perform at its best.

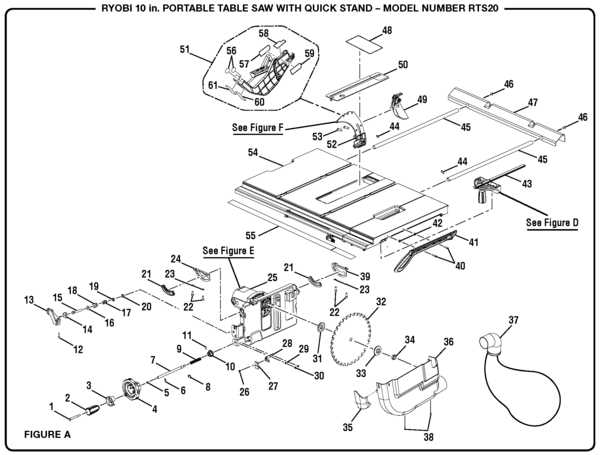

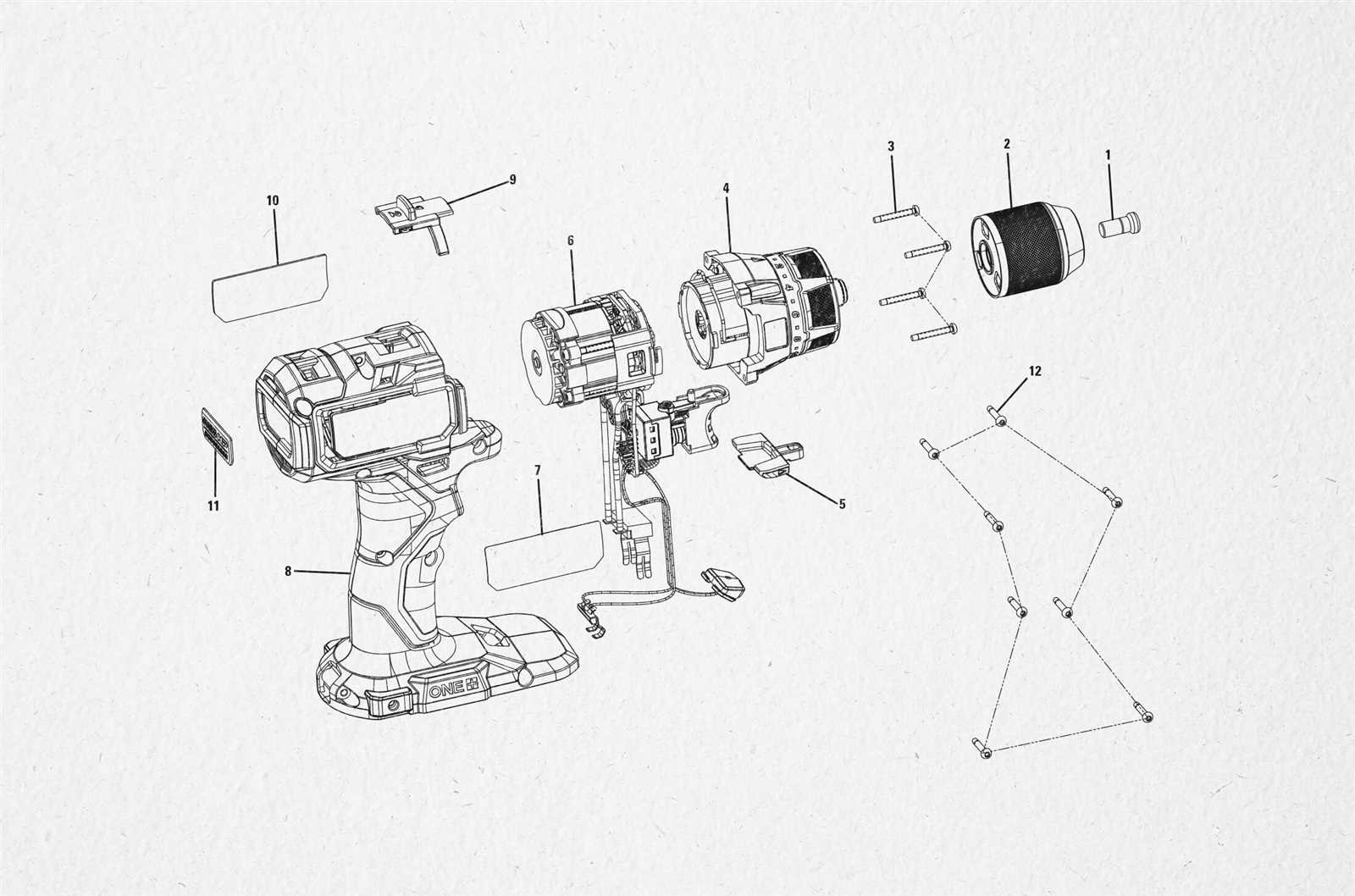

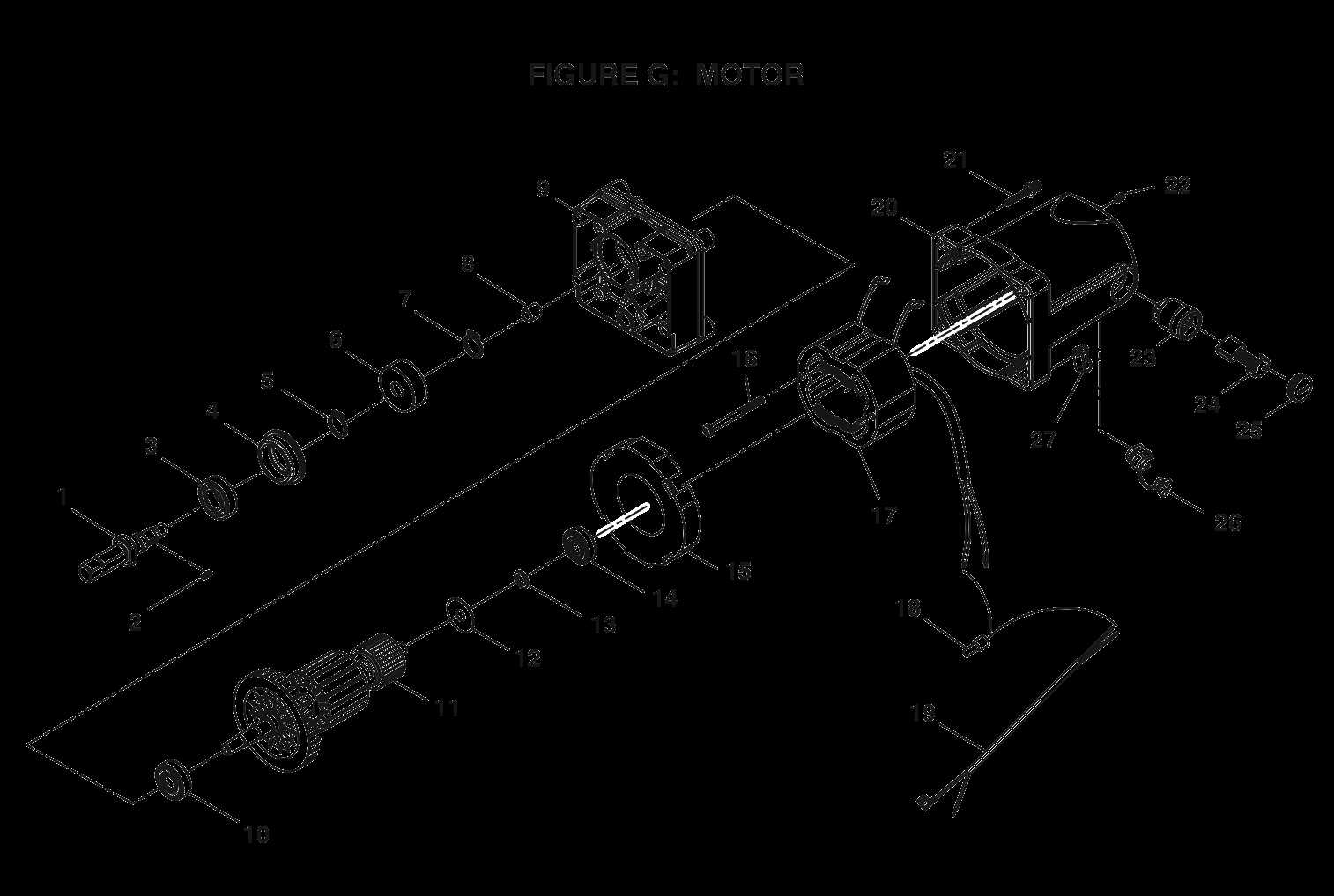

Identifying Key Components in the Diagram

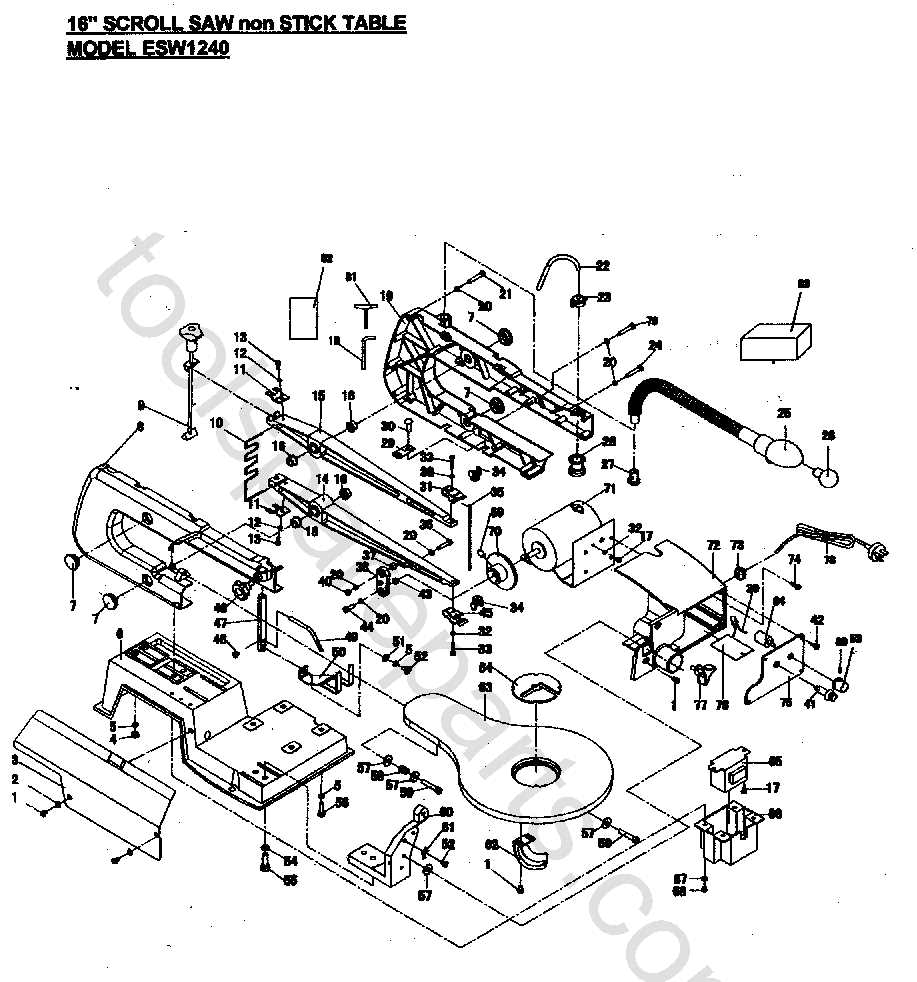

Understanding the layout of any complex tool requires recognizing its key elements and their specific functions. An in-depth visual guide is invaluable when it comes to identifying each piece, allowing users to better grasp how these components come together to ensure smooth operation. The clearer the breakdown of each part, the easier it becomes to maintain or repair the equipment effectively.

Each section of the tool serves a unique purpose, from the power system to the cutting mechanism and beyond. By studying these individual elements, you gain insight into their interaction, helping you diagnose issues or plan upgrades. Recognizing the role of each piece ensures that you address the right areas when performing maintenance or troubleshooting.

How to Use the Parts Diagram for Repairs

When it comes to fixing any piece of equipment, having a clear visual reference is crucial. A detailed illustration that labels all the essential components makes it easier to pinpoint issues, find replacements, and ensure proper reassembly. With such a guide, repair work becomes a more organized and efficient process.

To effectively use the reference guide for repairs, follow these steps:

- Identify the Problem: Begin by diagnosing the malfunction or damaged area of the tool. This will help you focus on the specific components that need attention.

- Locate the Relevant Components: Use the diagram to find the exact part or section of the tool that requires repair. Look for labels or markings to assist you in quickly identifying the right pieces.

- Check for Compatibility: Once you’ve identified the necessary components, ensure they match the specifications of your equipment. The guide can help you confirm that you’re using the correct replacements.

- Proceed with Repair: After gathering the right tools and replacement parts, carefully follow the instructions to disassemble and replace the faulty components.

By using the visual guide methodically, repairs become straightforward, and the risk of error is significantly reduced. This approach ensures that the tool will be back in optimal working condition with minimal effort.