Proper maintenance of any engine depends on a thorough understanding of its fuel delivery system. This system includes several critical elements that work in tandem to ensure optimal performance. Recognizing the components and their functions allows users to troubleshoot issues effectively and perform timely repairs.

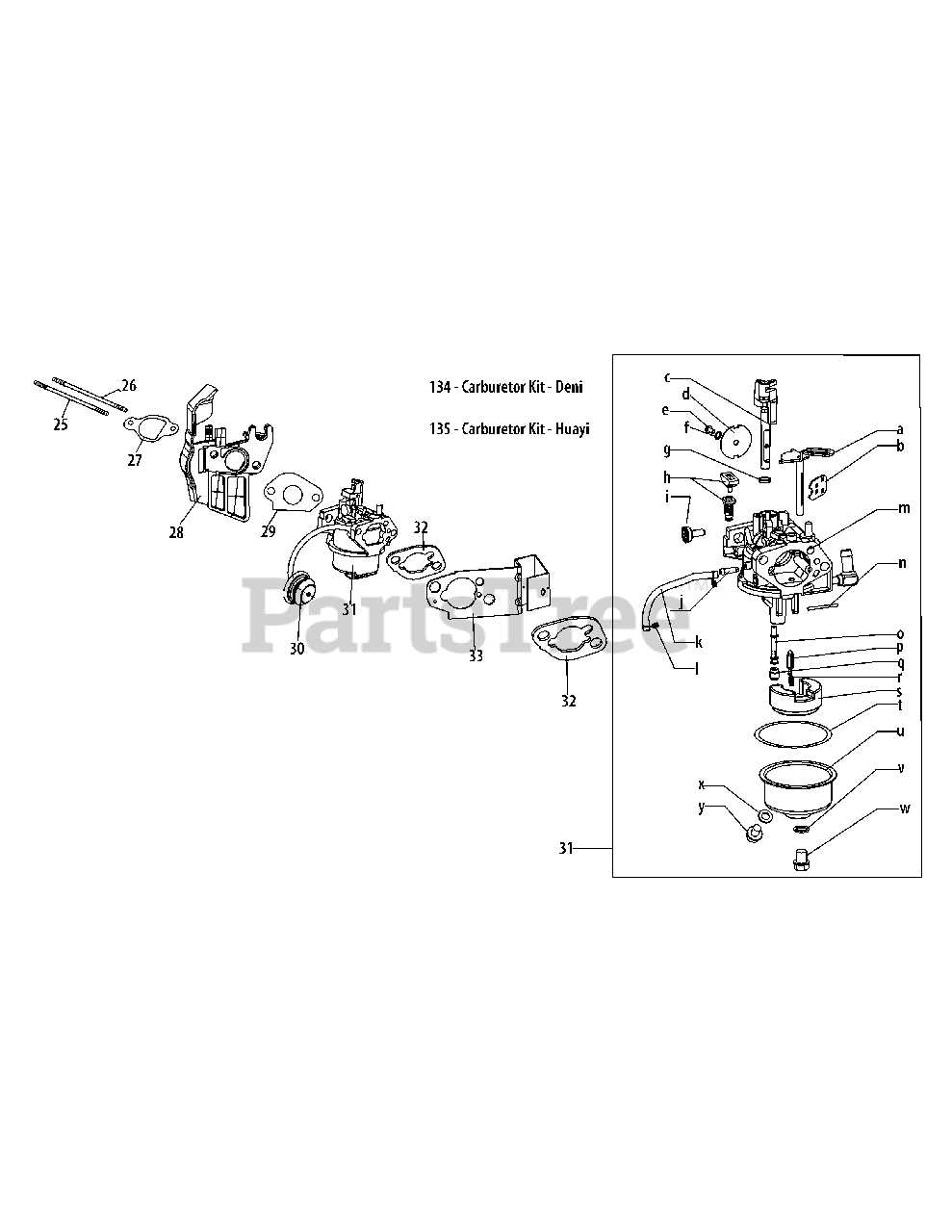

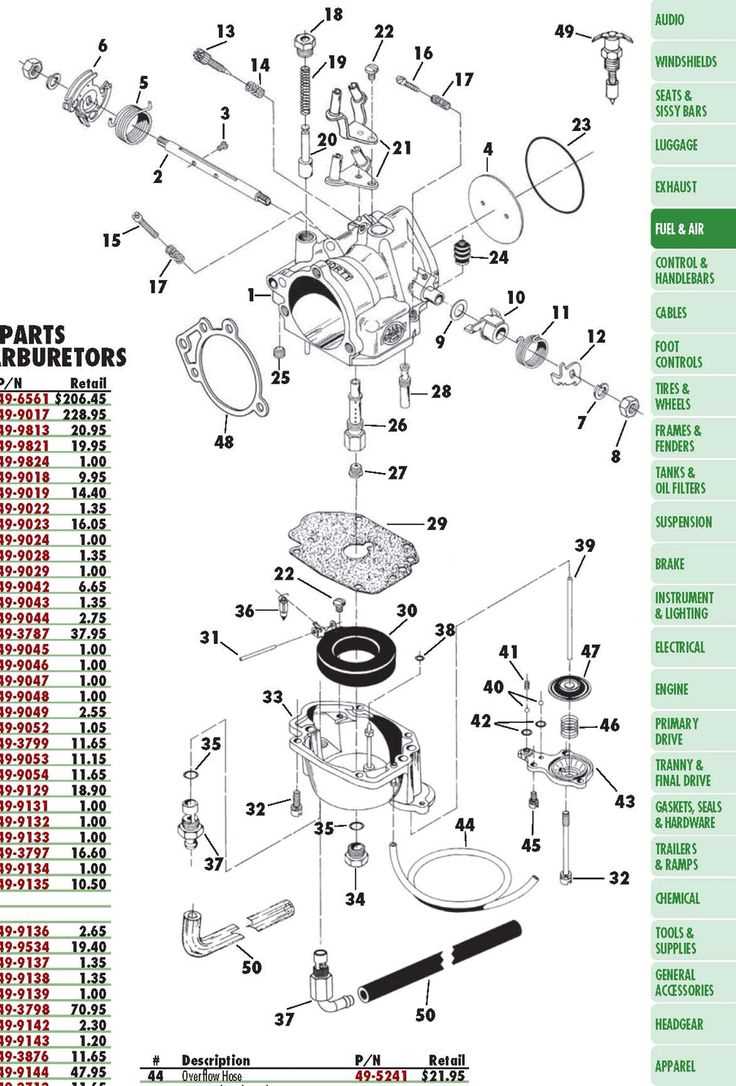

By breaking down the system into individual sections, it becomes easier to identify potential problems, such as fuel flow disruptions or inefficiencies. Clear diagrams can offer an excellent visual guide to understanding the layout of these parts and the role each one plays in the overall function.

Learning how to read and interpret these illustrations is an essential skill for anyone working with small engine repairs. With accurate information, users can ensure that each part is functioning as it should, leading to smoother operation and reduced downtime.

Understanding Engine Fuel System Components

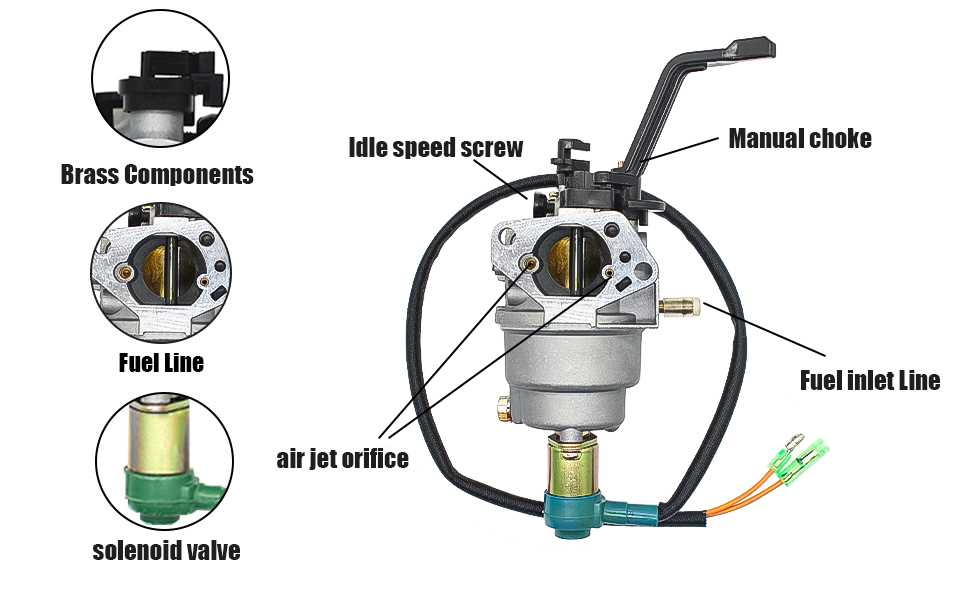

To ensure efficient engine operation, it is essential to grasp how the key elements of the fuel delivery mechanism interact. This system relies on various components, each playing a crucial role in managing fuel flow and air mixture for combustion. Understanding how these parts fit together is the first step in diagnosing issues and performing effective repairs.

The fuel system consists of several interconnected elements, from the inlet to the outlet, which work in unison to deliver the necessary mixture to the engine. Each part, whether it’s a valve, nozzle, or adjustment screw, has a specific function that influences overall performance. When one part fails or becomes clogged, the entire system may be compromised.

Having a clear understanding of the layout and functions of each component allows for better maintenance practices. Regular inspection and proper adjustments will help keep the engine running smoothly and prevent costly repairs down the line.

How to Read a Fuel System Layout

Interpreting a fuel system layout requires a careful understanding of how each element is represented and its role within the entire mechanism. These illustrations provide a visual guide to the placement, connections, and functions of individual components. By knowing what each symbol or line indicates, users can easily identify where problems might arise or which part requires attention.

Understanding Symbols and Connections

The layout typically uses simple symbols to represent different elements, such as valves, jets, and intake or exhaust components. Lines and arrows indicate flow directions or connections between parts. Familiarizing yourself with these symbols will allow you to quickly grasp how the system operates as a whole and how each component interacts with others.

Locating Problem Areas

Once you understand the basic structure, it becomes easier to pinpoint issues. If the engine is malfunctioning, the diagram can guide you to areas that are most likely to be affected. Knowing where each part fits into the larger picture can help identify damaged or blocked components, reducing troubleshooting time and improving repair efficiency.

Common Issues with Fuel Delivery Systems

Fuel systems often face a variety of issues that can affect engine performance, from poor starting to rough idling or stalling. These problems typically stem from either improper fuel mixture or blockages that prevent the smooth flow of fuel to the engine. Identifying and resolving these issues early is crucial for maintaining optimal engine function.

Clogged Fuel Jets: One of the most common problems is the clogging of fuel jets, which can restrict the flow of fuel into the combustion chamber. This usually happens when fuel becomes contaminated or when debris enters the system. Cleaning or replacing these jets is often the most effective solution.

Incorrect Air-Fuel Mixture: An improper air-fuel mixture can lead to inefficient combustion, causing the engine to run too rich (excess fuel) or too lean (insufficient fuel). Both conditions can result in poor performance, reduced fuel efficiency, and potential damage to internal components. Regular adjustments and fine-tuning can help maintain the correct mixture.

Fuel Leaks: Another common issue is fuel leakage, which can occur around seals or gaskets. Leaks can lead to fuel wastage, reduced engine performance, and potential fire hazards. Inspecting and replacing worn seals is essential to prevent leaks and ensure the system operates safely.