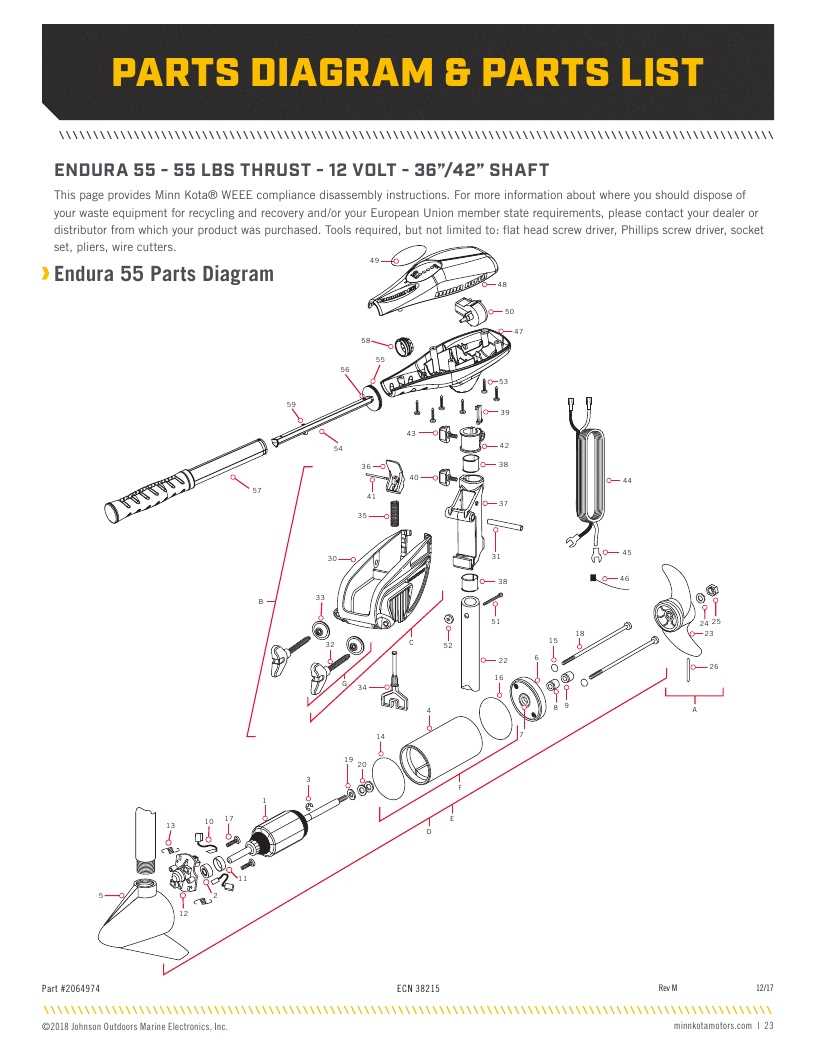

In this section, we will explore the essential elements of your motorized system, providing a detailed breakdown of its individual components. Knowing the layout and function of each part can significantly aid in both troubleshooting and enhancing the overall performance of your device.

The assembly of these systems involves various interconnected elements that work together to ensure smooth operation. Understanding how these parts relate to one another and their roles within the mechanism is vital for both maintenance and repair tasks.

Repairing or replacing specific parts may require a clear understanding of their placement and function. By reviewing the components systematically, you will gain a clearer perspective on how to keep your system running efficiently over time.

Understanding the Key Components

Every motorized system is built upon several critical elements that function in unison. Knowing the purpose and position of each piece ensures smooth operation and simplifies maintenance. This section will help you identify and understand these crucial components, allowing for better care and efficient use of your equipment.

Essential Components for Operation

- Drive Mechanism: Responsible for propelling the system forward, it is the core of the motion system.

- Control Unit: The heart of the electronics, which regulates speed, direction, and power.

- Housing: A protective cover that shields internal components from environmental factors.

- Propeller: An essential part for creating thrust and ensuring forward movement in water.

- Power Supply: Provides the necessary electrical energy for operation.

Importance of Each Element

Each part plays a significant role in the overall performance of the system. The drive mechanism provides the necessary propulsion, while the control unit allows the user to regulate the motor’s behavior. The housing protects delicate components from damage caused by water exposure, while the propeller ensures efficient movement. Lastly, the power supply must be consistent and reliable to avoid interruptions during use.

Familiarizing yourself with these components can help you identify issues quickly and make informed decisions during maintenance or repairs.

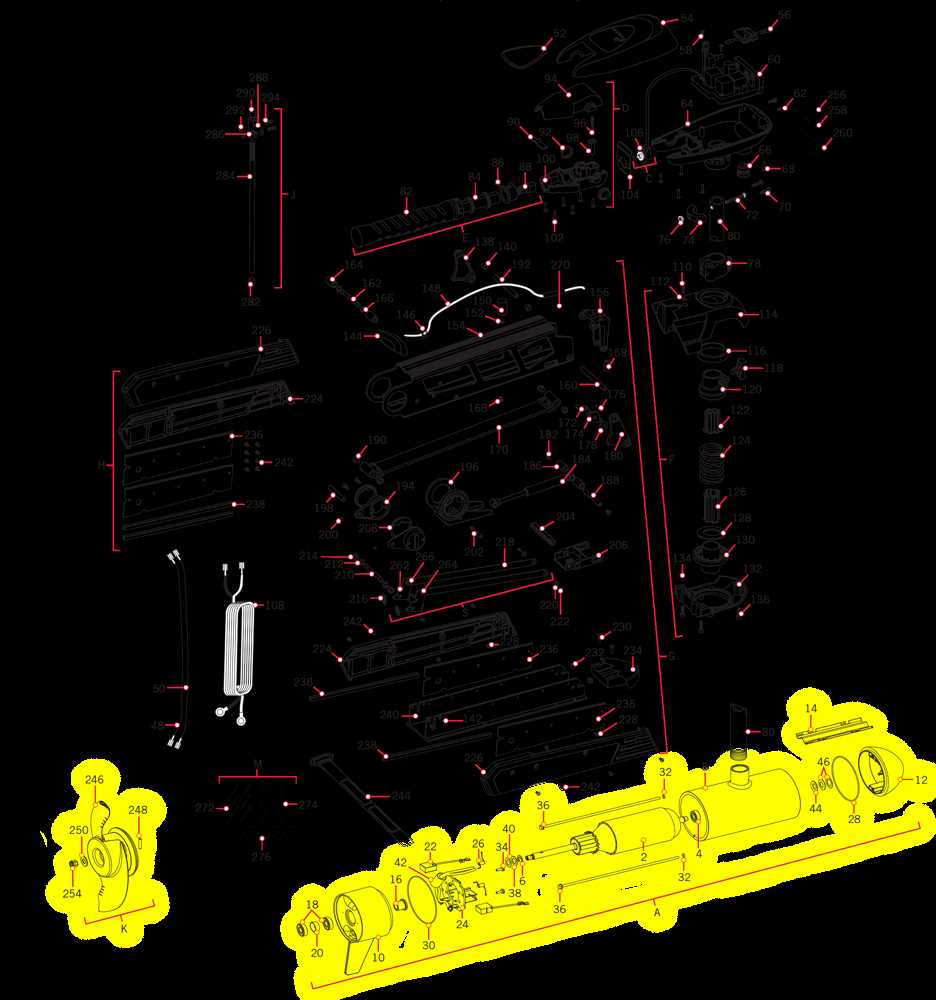

Key Components and Their Functions

Understanding the role of each key element within a motorized system is crucial for efficient operation and long-term reliability. Every component has a specific task, and together they form a cohesive unit. This section will delve into the main components, describing their functions and how they contribute to the overall performance.

Drive and Power Systems

- Drive Mechanism: The primary force behind the movement, responsible for translating electrical energy into motion.

- Motor Housing: Protects the internal working elements from damage while allowing heat dissipation.

- Power Source: Supplies the necessary energy for the motor’s operation, ensuring consistent performance.

Movement and Control

- Propeller: Converts rotational energy into thrust, propelling the system forward.

- Steering Mechanism: Allows users to control the direction of movement, ensuring precise navigation.

- Speed Controller: Regulates the rate of movement, providing smooth and responsive adjustments based on user input.

Each of these components works together to create a balanced system that delivers reliable and controlled operation. Recognizing their functions will help maintain the device and address issues when necessary.

Step-by-Step Assembly Process

Assembling your motor system requires careful attention to detail, ensuring that each component is placed correctly for optimal performance. This process involves connecting different units in a specific order to ensure efficiency and reliability. Following these steps will guide you through the assembly, helping you avoid common mistakes and ensuring everything is set up properly.

Preparing the Components

Before starting, ensure that all necessary components are available and in good condition. This includes checking the motor housing, propeller, and control unit for any damage. Make sure all screws, nuts, and bolts are organized for easy access during the assembly process.

Assembly Steps

- Start with the motor housing: Attach it to the base platform securely, ensuring it is aligned properly.

- Install the drive mechanism: Position it inside the housing and connect it to the power source, making sure the wiring is correctly positioned.

- Mount the propeller: Attach it to the drive unit, ensuring it is tightly secured and rotates freely.

- Connect the control unit: Place it in its designated position and connect all necessary wires to the motor for power and control.

- Double-check connections: Review all connections to ensure they are tight and correct to prevent future issues.

Once all components are securely assembled, perform a test run to ensure everything is functioning correctly. Adjust as needed to achieve the desired performance.

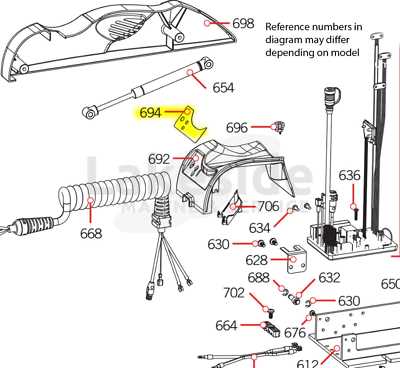

How to Put Together the Motor

Assembling the motor involves connecting key components in the right sequence to ensure proper functionality. Each element must be carefully aligned and secured to guarantee smooth operation. In this section, we will walk through the essential steps for putting together the motor, focusing on the assembly process to avoid common mistakes.

Step-by-Step Assembly

Follow these instructions for an efficient assembly:

| Step | Action | Details |

|---|---|---|

| 1 | Prepare the Base | Place the motor base on a stable surface and ensure that the area is clean and organized. |

| 2 | Attach the Motor Housing | Secure the motor housing to the base using the appropriate screws and make sure it is aligned correctly. |

| 3 | Install the Drive Mechanism | Carefully position the drive unit inside the housing and ensure that the connections are properly made to the power source. |

| 4 | Mount the Propeller | Attach the propeller to the drive unit, ensuring it is properly secured and rotates freely without obstruction. |

| 5 | Connect the Control Unit | Place the control unit in its designated spot and connect the wiring to the motor system, ensuring all connections are secure. |

Once these steps are completed, perform a test to ensure the motor is functioning correctly. This will help verify that all components are properly assembled and working together.

Maintaining and Replacing Components

Proper maintenance and timely replacement of worn or damaged elements are key to ensuring the longevity and performance of your system. Regular checks, cleaning, and the use of quality replacement parts can prevent breakdowns and extend the life of your equipment. In this section, we will explore essential maintenance practices and offer guidance on when and how to replace critical components.

Routine Maintenance Tips

- Regular Cleaning: Keep all components clean and free from debris, particularly the motor and propeller, to ensure smooth operation.

- Inspection of Electrical Connections: Check wiring for any signs of wear, corrosion, or loose connections that could impair performance.

- Lubrication: Apply appropriate lubricants to moving parts, such as the drive mechanism, to reduce friction and prevent damage.

- Storage: When not in use, store the unit in a dry place to avoid exposure to elements that could cause rust or corrosion.

When to Replace Key Elements

- Motor Housing: Replace if it shows signs of cracks, damage, or water leakage that could compromise the internal components.

- Propeller: If the propeller is cracked, bent, or severely worn, it should be replaced to maintain efficient movement.

- Power Supply: If the system loses power or does not run properly, it may be time to replace the power source or battery.

- Control Unit: If there is no response to adjustments or if the system fails to operate correctly, the control unit may need to be replaced.

By staying on top of regular maintenance and addressing worn-out components quickly, you can ensure that your system remains reliable and efficient over time.