Understanding the internal structure of your welding equipment is essential for proper maintenance and efficient operation. This knowledge helps troubleshoot issues and ensures the longevity of the machine. Knowing how all the components fit together allows for easier repairs and reduces downtime in the workshop.

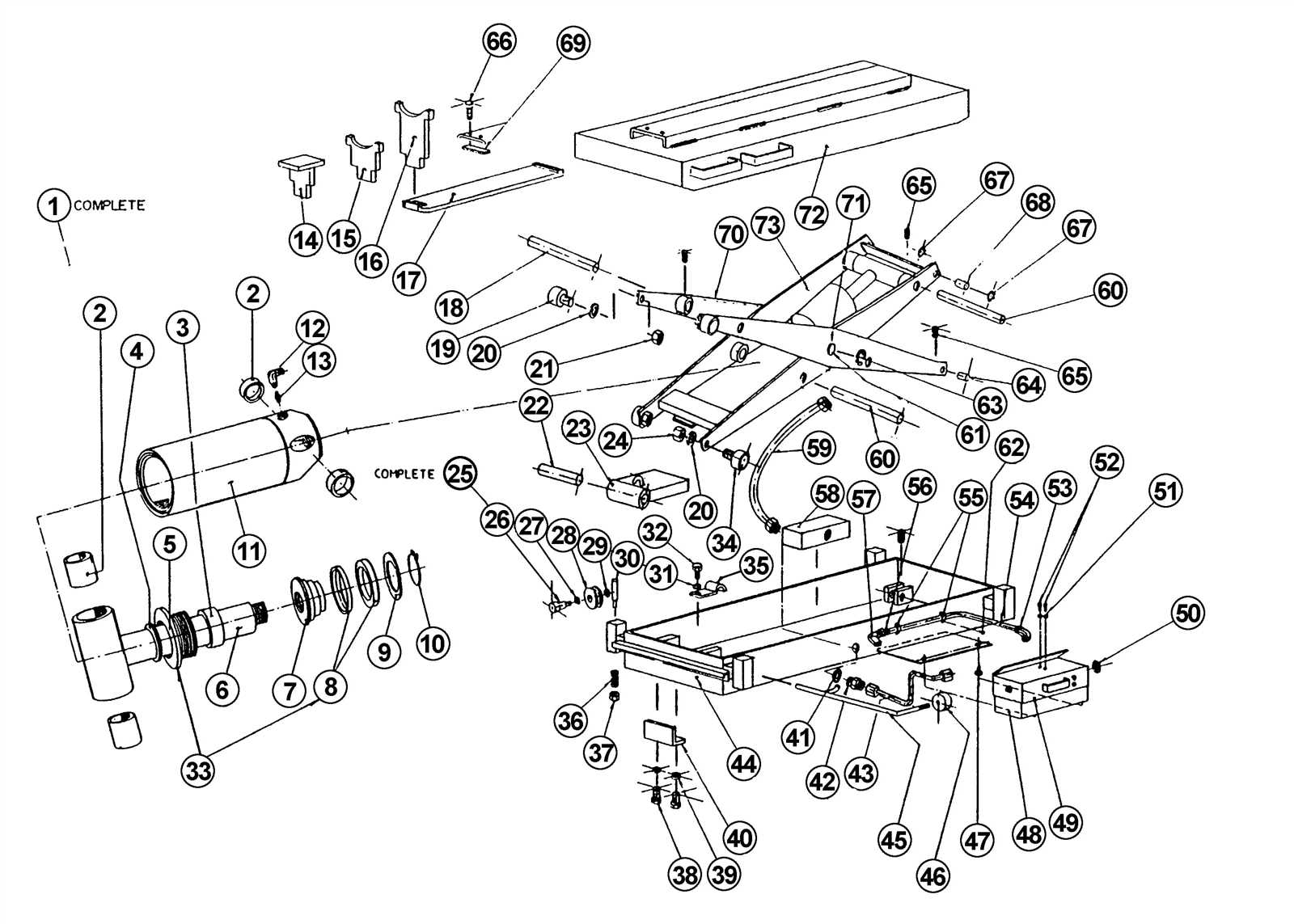

The exploded view of the machine’s elements provides a clear insight into its assembly and functionality. With this detailed reference, you can identify each part and learn its role in the system. Whether you’re performing routine inspections or addressing specific faults, a thorough understanding is key.

Regular maintenance and proper handling of the equipment are critical. With the right guidance, any user can confidently manage their machine’s upkeep, avoiding costly repairs and ensuring consistent performance in demanding tasks.

Understanding the Welding Machine Components

Every welding machine is composed of various essential components that work together to provide reliable performance. By familiarizing yourself with these parts, you can better understand how the equipment operates and how to maintain it efficiently. Proper knowledge helps in diagnosing issues, performing repairs, and ensuring that the machine operates smoothly over time.

Key Elements of the Welding System

The core structure of the machine includes critical components such as the power supply, cooling system, and control panel. Each part plays a vital role in the overall functioning of the system. The power supply converts electrical energy into usable power for welding, while the cooling system prevents overheating during heavy use. The control panel offers the user the ability to adjust settings, monitor the status, and ensure optimal output during welding tasks.

Importance of Regular Inspections

Routine checks and maintenance are crucial to ensure the machine operates at peak efficiency. Regularly inspecting the components for wear and tear, as well as keeping an eye on any signs of malfunction, can prevent costly repairs and downtime. By understanding the machine’s structure, you can quickly identify issues and address them before they affect performance.

How to Read the Machine Assembly Guide

Understanding an exploded view of a welding machine can be challenging without the right knowledge. These visual representations are designed to help users identify the position and relationship between various components. By carefully studying the guide, you can easily locate individual parts and understand how they contribute to the overall function of the equipment.

Interpreting the Visual Layout

The layout typically features a detailed illustration of the machine, with each component labeled for easy identification. The guide often uses lines or arrows to show how parts fit together, making it easier to follow the assembly process. Each item is numbered or marked, allowing you to reference the corresponding part list for detailed information.

Using the Reference List

Alongside the visual guide, there is usually a reference list that matches each number or label with specific part names, descriptions, and sometimes, part numbers. This list is essential when ordering replacements or understanding the role of each component. It provides a more in-depth understanding of how each piece functions within the system.

Common Maintenance and Repair Tips

Regular maintenance is crucial to ensure the longevity and reliable performance of your welding equipment. Taking proactive steps to care for your machine can prevent costly breakdowns and minimize the need for major repairs. Simple tasks like cleaning, checking for wear, and replacing damaged components can keep the machine running efficiently for years.

Routine Cleaning and Inspection

Cleaning the machine after every use is essential for preventing dust and debris buildup, which can lead to overheating or malfunctions. Regularly inspect the cooling system, power cables, and electrical connections for any signs of wear or damage. Keeping these areas clean and well-maintained reduces the risk of issues arising during operation.

Replacing Worn or Damaged Components

Over time, certain parts of the machine may become worn out or damaged due to frequent use. It’s important to replace these components promptly to prevent further damage to the equipment. Always use the correct replacement parts to maintain the machine’s functionality and avoid compromising its performance.