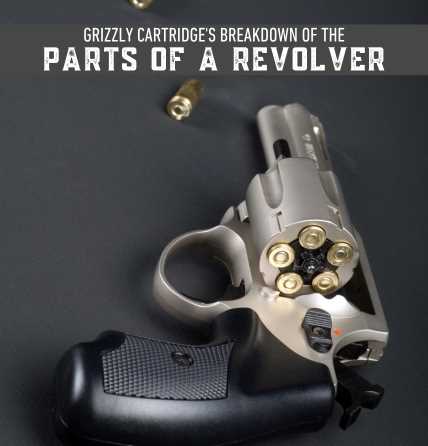

When it comes to firearm maintenance, having a clear understanding of its inner workings is essential. The ability to identify each piece and how they interact allows for more effective repairs, adjustments, and improvements. A detailed visual representation of the firearm’s components can be a crucial tool for both professionals and enthusiasts alike.

Whether you are disassembling your weapon for cleaning or replacing a worn-out piece, a comprehensive guide can make all the difference. With the right instructions, identifying the correct components and knowing how to assemble or repair them becomes much simpler, saving time and avoiding potential mistakes.

Accurate diagrams serve as a reliable reference point, helping individuals understand the precise location and function of each element, making any task related to the firearm more manageable and efficient.

Understanding Firearm Component Breakdown

In the world of firearm maintenance, having a thorough understanding of each individual element is crucial. A visual guide can simplify the identification of each part, helping users see how everything fits together. Knowing the function and location of each component ensures that disassembly and reassembly are done correctly, which is vital for performance and safety.

Importance of Accurate Component Identification

Each piece of the firearm plays a specific role in its operation, and understanding these roles is essential for any type of repair or upgrade. By studying a well-detailed chart, you can ensure that you’re working with the correct components and avoid mistakes that could lead to malfunction or damage. Clear identification aids in more effective repairs, maintenance, and troubleshooting.

Benefits for Repair and Maintenance

For anyone looking to perform repairs, knowing exactly where each part fits within the assembly can make the process smoother. A well-designed reference image provides clarity, ensuring the technician or enthusiast does not waste time guessing or misplacing components. With a detailed breakdown, users can approach their work with confidence and precision.

How to Use the Firearm Component Guide Effectively

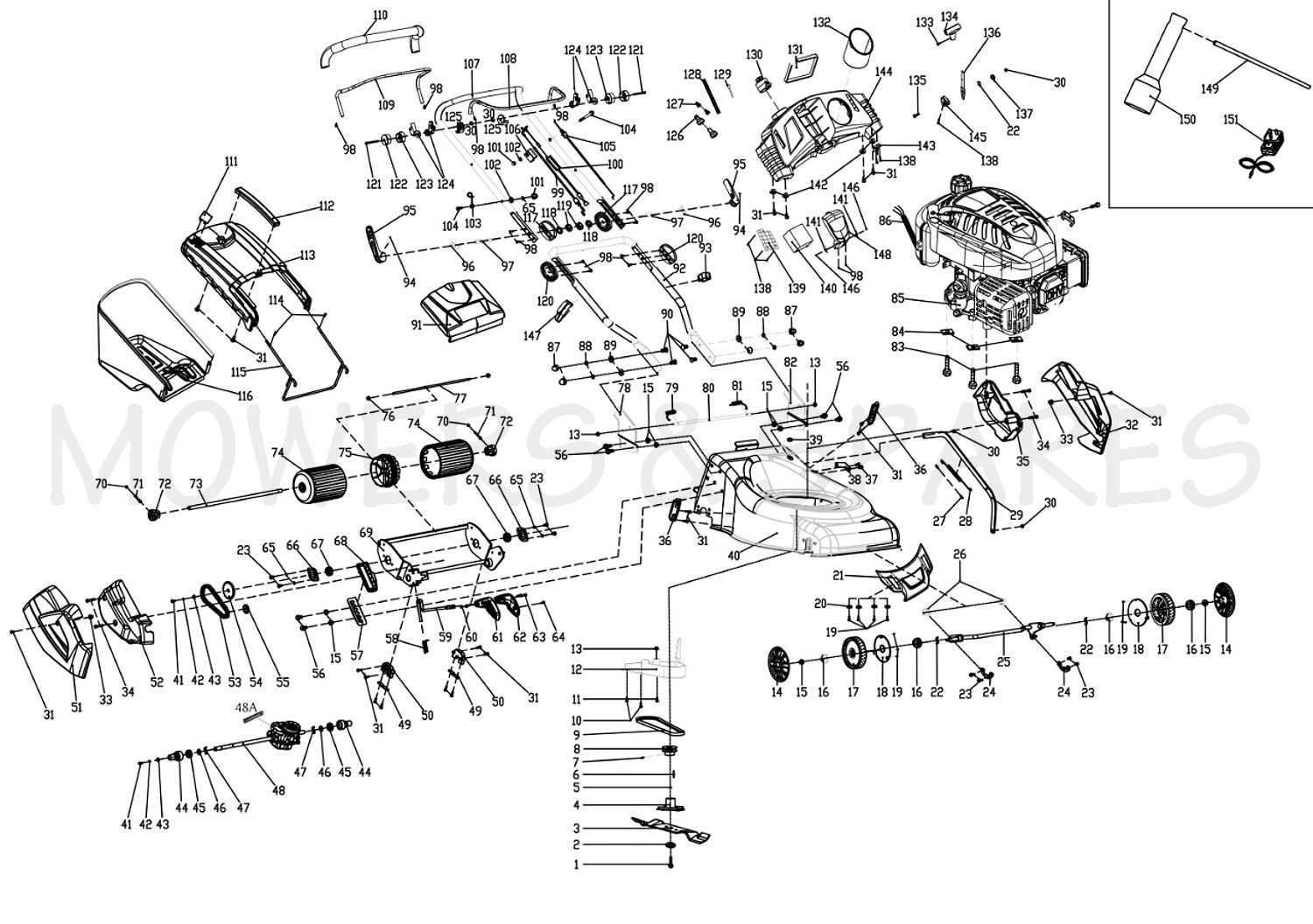

To make the most of a visual reference for firearm maintenance, it’s important to approach it with a clear understanding of its structure. Knowing how to navigate the guide will save you time and prevent errors. With the right techniques, you can use the reference as a valuable tool for both disassembly and reassembly.

Step-by-Step Approach to Assembly and Disassembly

Start by carefully reviewing the image and familiarize yourself with the components and their positions. Focus on understanding the function of each piece before attempting any adjustments. Break down the process into manageable steps, using the guide to identify each part’s placement. This approach reduces confusion and ensures that no part is overlooked or incorrectly assembled.

Common Mistakes to Avoid

One common mistake is rushing through the process without double-checking the reference material. It’s easy to assume a part fits in a certain position when it actually doesn’t. Take the time to verify each part’s placement, especially when working with smaller components that might be hard to distinguish.

Common Issues and Solutions for Firearm Components

Even the most reliable firearms can encounter problems over time. Understanding the typical issues that may arise with the internal components is essential for effective troubleshooting. By recognizing these common problems and knowing the appropriate solutions, you can restore your weapon’s functionality quickly and safely.

Wear and Tear on Small Components

One of the most frequent problems is the wear of small internal pieces, such as springs and pins. These components may degrade with extended use, leading to issues like failure to cycle or misfires. Regular inspection and timely replacement of these parts can prevent these problems from becoming more serious. Be sure to use high-quality replacements to ensure proper function and longevity.

Misalignment and Improper Assembly

Another common issue is the misalignment of parts during reassembly. If components are not correctly aligned, the firearm may malfunction or even become unsafe to use. Following a clear reference guide during reassembly ensures that everything is properly positioned, reducing the risk of this issue. Always double-check alignment before final assembly to avoid costly mistakes.