Maintaining and repairing any machinery requires a clear understanding of its individual parts and their interactions. For chainsaw owners, having access to a detailed breakdown of the equipment is crucial for efficient service and trouble-free operation.

By examining the structure of the tool, users can identify potential issues, replace worn-out components, and perform essential maintenance tasks. A visual map of the various sections provides a straightforward way to navigate the system, ensuring proper care.

Understanding the layout not only helps in quick repairs but also improves the longevity of the device. Whether you’re looking to enhance its performance or resolve a malfunction, the right approach begins with a comprehensive overview of its inner workings.

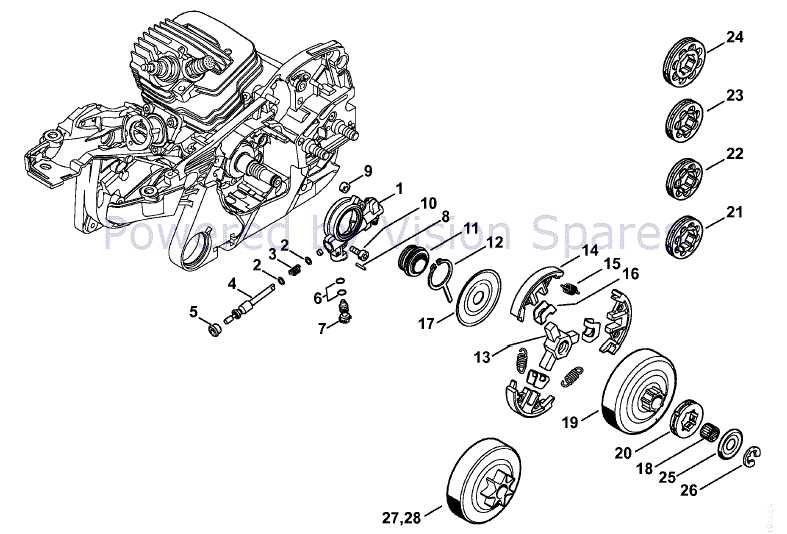

Understanding Stihl MS261 Parts Layout

Having a clear view of the internal structure of any mechanical tool is essential for proper maintenance and efficient repairs. Knowing the layout of each component allows for easier identification of problems and quicker solutions. This understanding enhances the performance of the machine and extends its service life.

Main Sections of the Tool

Each tool is made up of various sections that work in harmony. Key elements such as the engine, fuel system, and cutting mechanisms form the backbone of the machinery. Understanding the placement and function of these elements is important for proper upkeep and troubleshooting.

Identifying Essential Components

By examining the layout carefully, users can pinpoint crucial components, such as the drive system, ignition, and air filter, which often require the most attention. A visual representation of how these parts fit together helps users handle maintenance tasks with precision.

Key Components of the MS261 Chainsaw

Every chainsaw consists of several critical components that work together to ensure smooth operation. Understanding these essential parts is vital for effective maintenance and troubleshooting. Knowing how each part functions allows users to identify potential issues and perform necessary repairs quickly.

Engine and Power System

The engine is the heart of any chainsaw, providing the power needed to drive the chain and other mechanisms. It consists of various elements, including the cylinder, piston, and spark plug, which require regular checks to maintain optimal performance.

Cutting Mechanism and Chain Drive

The cutting mechanism is what allows the tool to perform its primary function. It includes the chain, guide bar, and sprocket, all of which should be properly aligned and maintained. Ensuring the smooth operation of these components is essential for efficient cutting and safety.

How to Use the Parts Diagram Effectively

Visual guides that break down the internal structure of machinery can be extremely helpful when performing maintenance or repairs. By carefully studying these guides, users can identify the different sections and components, making it easier to locate issues and replace damaged elements. Proper usage of these guides ensures a more efficient repair process and reduces the likelihood of mistakes.

Step-by-Step Navigation

Start by locating the key sections in the guide. Understanding the general layout of the machine allows for easier identification of the most relevant parts. Once familiar with the layout, you can quickly find the specific components that need attention or replacement.

Cross-Referencing with Manuals

For further precision, cross-reference the guide with the official user manual. This ensures that you are using the correct terminology and part numbers for ordering replacements. Additionally, referring to the manual can provide insights into the proper installation and maintenance procedures for each component.