When maintaining or repairing any mechanical tool, having a clear understanding of its structure is essential. By breaking down each section, you can ensure that all parts are functioning properly and can be easily replaced if needed. This approach helps in both troubleshooting issues and performing regular maintenance tasks.

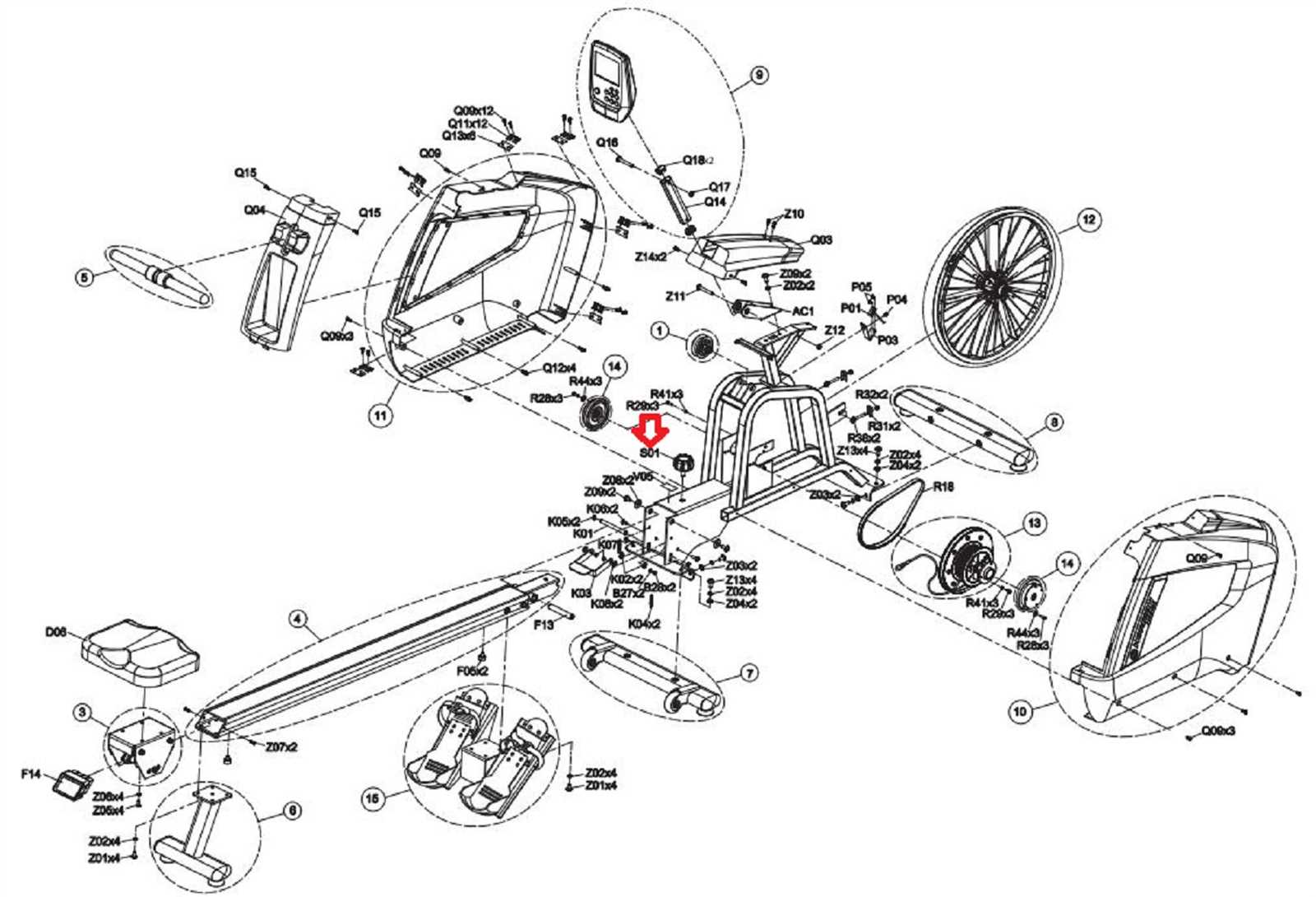

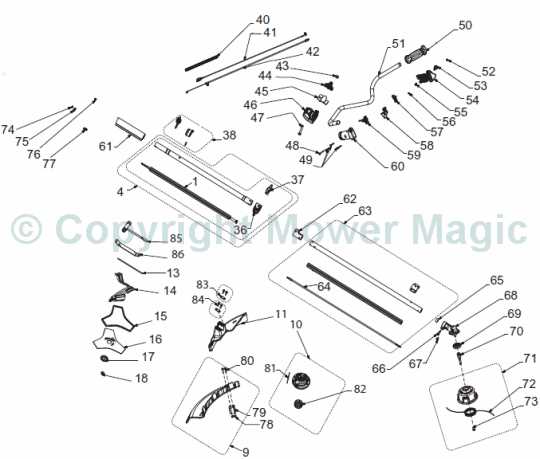

Identifying each individual component plays a crucial role in diagnosing problems or making improvements. Whether you are replacing a worn-out piece or assembling your equipment for the first time, a thorough knowledge of each part’s role ensures a smoother experience.

Additionally, knowing the right components to focus on can save time and effort when working with your tool. By referring to a detailed layout, you can quickly find the necessary pieces and avoid unnecessary confusion during the repair process.

Complete Breakdown of Key Components

Understanding the structure of any mechanical tool is critical for proper upkeep and repair. In this section, we will look at the main components that make up your equipment, highlighting their individual roles and functions. This breakdown allows you to see how each part contributes to the overall operation and performance.

Core Elements and Their Functions

The core structure consists of several essential units that work together to ensure smooth operation. These parts typically include the engine, transmission, and other core mechanisms that allow the tool to perform its tasks efficiently. Recognizing these components helps in determining what needs attention when issues arise or during regular servicing.

Auxiliary Components for Enhanced Performance

Alongside the primary elements, there are various auxiliary components designed to enhance performance, such as switches, handles, and safety features. These components are just as important for providing ease of use and ensuring safety. Regular inspection of these smaller parts can prevent larger issues and maintain operational integrity.

Essential Components and Their Functions

In every mechanical device, there are key elements that play a crucial role in ensuring smooth and efficient operation. These components are designed to work together, each serving a specific function to contribute to the overall performance of the system. Understanding the purpose of each element can help in troubleshooting, repairs, and maintenance, ensuring the longevity of the device.

Power and Transmission Mechanisms

The power mechanism is responsible for generating the energy needed for the system to operate. Coupled with the transmission components, it ensures that this energy is efficiently transferred to the necessary parts. These mechanisms work in tandem to provide the required force for the equipment to function properly.

Control and Adjustment Systems

The control systems are designed to regulate the operation of the device, allowing users to adjust settings such as speed, intensity, or direction. These components are essential for fine-tuning the system according to specific tasks, offering flexibility and precision in its performance.

How to Identify and Replace Components

Identifying and replacing damaged or worn-out elements in a device is an essential part of maintaining its functionality. Recognizing when a component needs replacement is key to preventing further damage and ensuring optimal performance. This process involves inspecting each part carefully and understanding its role within the system, followed by replacing it with a compatible new part.

Start by carefully examining the device for any signs of wear, damage, or malfunction. Look for components that show signs of stress, such as cracks, fraying, or unusual movement. Once you’ve identified the faulty part, find the correct replacement by checking the specifications. After obtaining the replacement, follow the manufacturer’s instructions for proper installation to ensure the device operates as intended.