When maintaining a lawn mower, knowing the layout of its individual elements is essential for proper care and repairs. A clear understanding of how different sections interact helps ensure smoother operation and efficient troubleshooting. Identifying each component’s role within the machine can save time and prevent costly mistakes during maintenance tasks.

In this guide, we will explore how to read and interpret the visual representation of mower components. By breaking down the structure and offering insights into common issues, we aim to simplify the process of repairs and upkeep. Whether you are a novice or an experienced user, having access to an organized reference can make all the difference in effective mower management.

Proper knowledge of mower assemblies can also reduce wear and tear, leading to a longer lifespan for the equipment. Through step-by-step instructions, you will gain confidence in recognizing the key elements that keep your mower running smoothly.

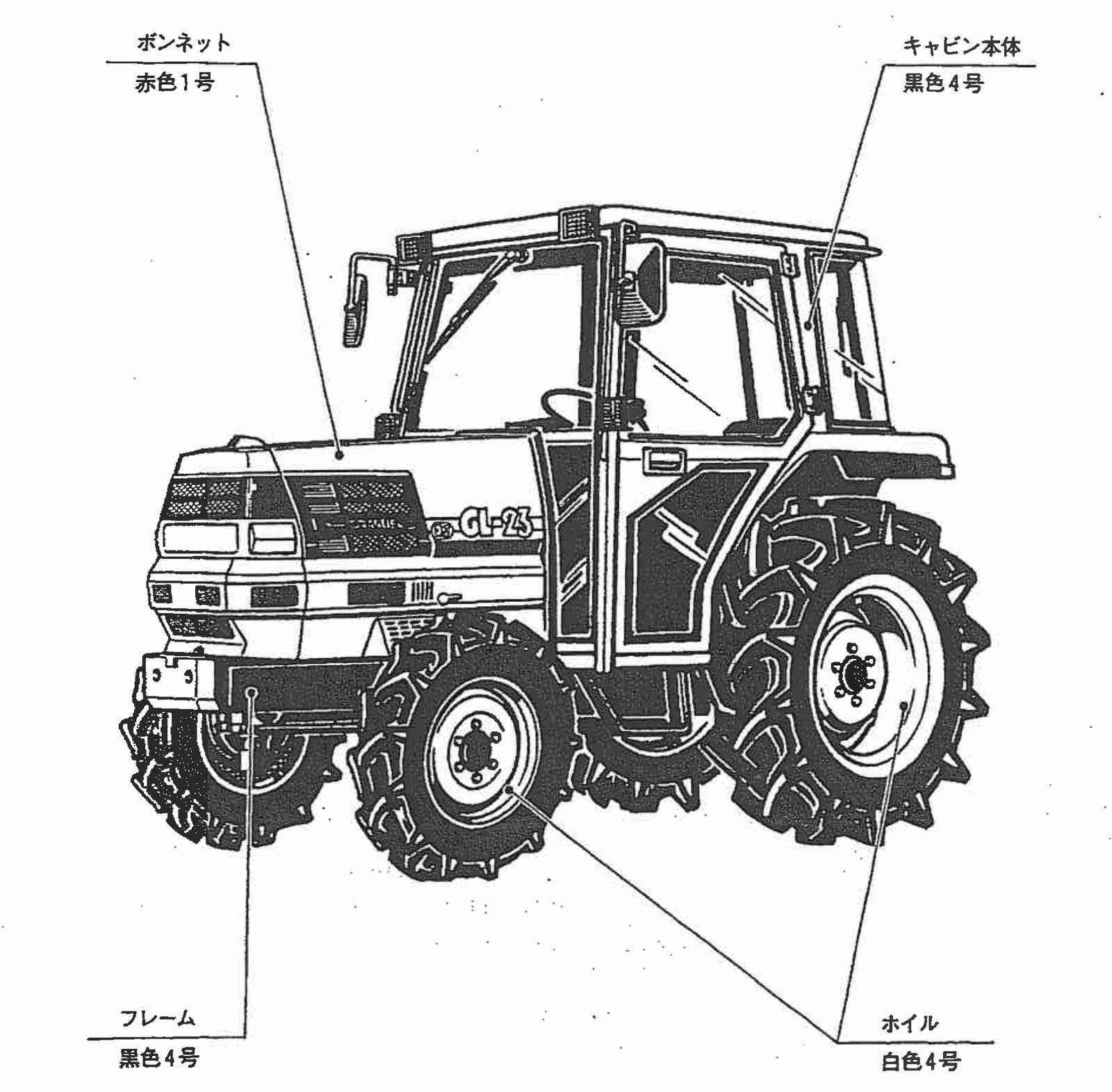

Overview of Kubota ZG23 Parts

Understanding the essential components of a lawn mower is crucial for effective operation and maintenance. Each part plays a unique role in ensuring smooth functionality, and being familiar with them helps users address potential issues with ease. A well-organized system of components allows for more accurate troubleshooting and faster repairs.

Below is a breakdown of key assemblies and their functions in the machine:

- Engine: The heart of the mower, responsible for powering the entire machine.

- Transmission: Manages the power delivery to the wheels, ensuring the mower moves smoothly.

- Blades: The cutting mechanism, essential for trimming grass and vegetation evenly.

- Steering System: Allows precise control of the mower’s direction for effective maneuvering.

- Fuel System: Ensures the engine has the proper fuel supply to run efficiently.

- Electrical System: Powers the ignition and other vital electrical components like lights and sensors.

- Cooling System: Prevents the engine from overheating, maintaining optimal operating temperatures.

Each of these assemblies contains various smaller components, all of which work in tandem to keep the mower functioning at its best. By becoming familiar with the names and locations of these parts, operators can perform routine checks and resolve issues promptly before they lead to more significant problems.

Essential Components and Their Functions

Every machine relies on a set of core elements that work together to ensure efficient operation. These fundamental components are responsible for the overall performance, and understanding their functions helps in maintaining and troubleshooting the equipment effectively. Each part plays a specific role, from providing power to managing movement, contributing to the smooth running of the mower.

Among the most important components are:

- Engine: Powers the entire system, converting fuel into energy needed to drive the machine.

- Transmission: Transfers the engine’s power to the wheels, allowing the mower to move at varying speeds and directions.

- Cutting Mechanism: Includes the blades, which trim grass and other vegetation with precision.

- Steering Assembly: Provides control over the direction of the mower, allowing for accurate navigation and maneuvering in tight spaces.

- Fuel System: Ensures the engine receives a continuous supply of fuel to maintain smooth operation.

- Electrical System: Powers critical features such as ignition, lights, and sensors, ensuring all electrical functions are operational.

- Cooling System: Maintains an optimal engine temperature, preventing overheating during extended use.

Each of these systems is vital to the mower’s ability to perform its tasks efficiently. Proper maintenance of these components ensures the longevity of the machine and reduces the likelihood of breakdowns during operation.

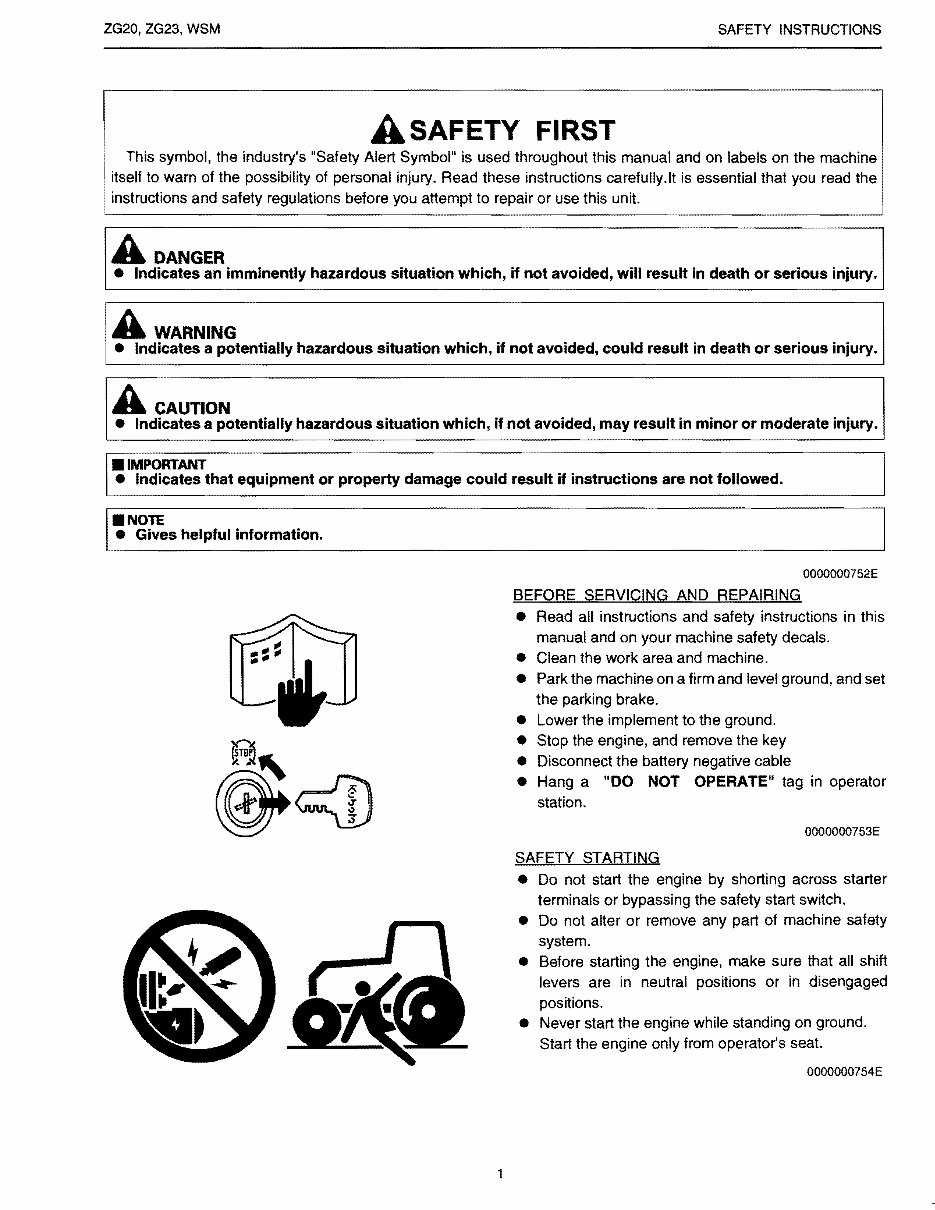

How to Interpret ZG23 Diagrams

Reading and understanding technical diagrams is an essential skill for anyone maintaining or repairing machinery. These visual representations provide a detailed overview of how various components are arranged and connected. By interpreting these illustrations correctly, users can easily identify the parts that require attention, leading to more efficient repairs and maintenance.

To effectively navigate a technical illustration, follow these key steps:

- Identify the Sections: Diagrams are often divided into sections that correspond to different parts of the machine. Focus on each section individually to better understand its function.

- Examine the Labels: Pay close attention to the labels and annotations provided on the diagram. These will help clarify each component’s purpose and location.

- Understand the Flow: Look for arrows or lines that indicate how power or movement flows between components. This can give insight into the machine’s overall operation.

- Cross-Reference with the Manual: Use the machine’s manual to cross-reference the diagram and ensure that all parts are correctly identified and understood.

- Look for Key Dimensions: Some diagrams will include measurements or other technical data to help with part replacements or adjustments. Make sure to check these for accuracy.

By mastering these techniques, interpreting technical illustrations becomes an easier and more straightforward task, empowering users to perform maintenance with confidence.

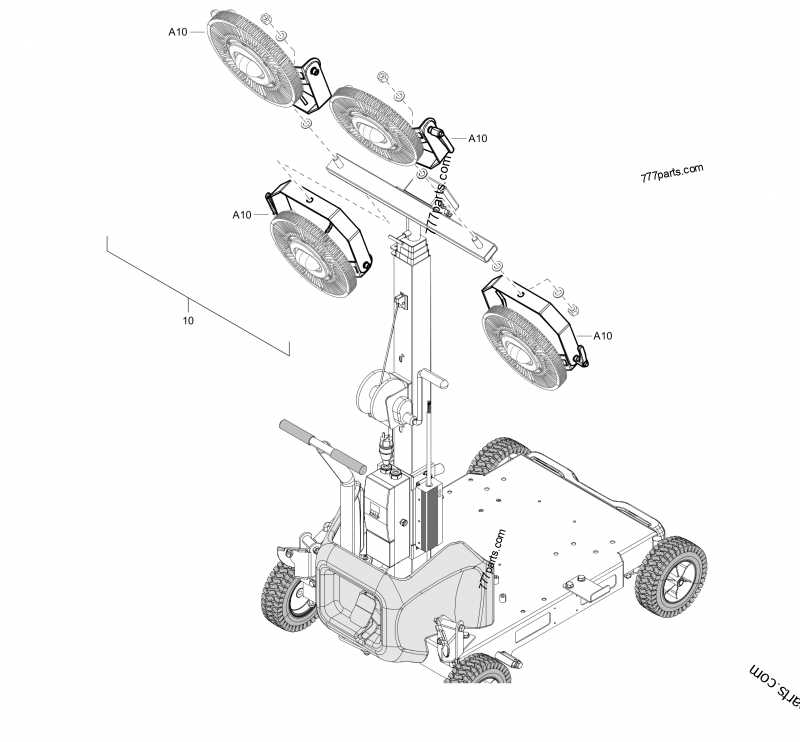

Guidelines for Understanding Parts Layout

When examining a technical layout, it is essential to focus on how various elements are arranged and connected. A clear understanding of this layout can significantly enhance your ability to perform repairs and maintenance tasks. The arrangement often follows a logical sequence that makes troubleshooting simpler and part identification quicker.

Here are some key guidelines to help you interpret the layout effectively:

- Start from the Core: Begin by identifying the central components that drive the machine, such as the engine or power system, and work your way outwards.

- Look for Groupings: Similar parts are often grouped together. For example, all elements related to the cutting system may be in one section, while the powertrain components are in another.

- Check for Connections: Pay attention to lines or arrows that show how components are connected. These can indicate fuel, electrical, or mechanical connections that are critical to the machine’s functioning.

- Review Component Numbers: Each part may have a reference number or code that allows you to find it in the machine’s manual or inventory. Ensure these numbers match the components during identification.

- Understand Component Size and Position: Some layouts will show parts in relative size or position, which helps in understanding their role within the whole system.

By following these simple steps, you can gain a better grasp of how individual elements work together and streamline the repair or maintenance process.

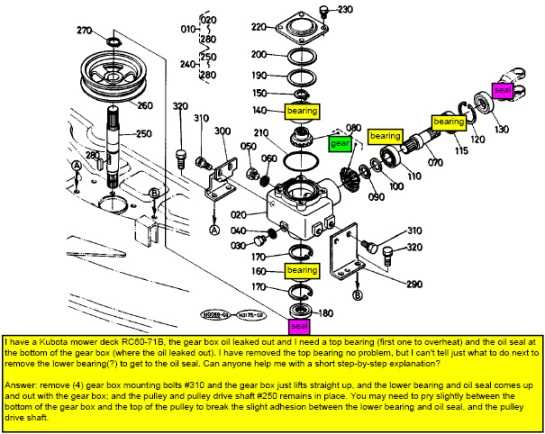

Troubleshooting Kubota ZG23 Issues

When a machine begins to show signs of malfunction, quick identification of the underlying problem is essential for effective resolution. By systematically reviewing the different components, most issues can be diagnosed and corrected without professional assistance. Recognizing common problems and understanding their causes can save both time and resources.

Engine Won’t Start

If the engine fails to start, the first step is to check the fuel system. Ensure the tank is full and that there are no clogs in the fuel lines. If fuel is reaching the engine, check the ignition system for any malfunctioning components, such as a faulty spark plug or worn-out ignition switch. Additionally, confirm that the battery is fully charged and connected properly, as electrical failure is another common culprit.

Machine Not Moving Properly

When the machine is not moving as expected, the issue may lie within the transmission system. Inspect the belts and pulleys for wear, ensuring they are properly aligned and in good condition. If the issue persists, check the hydraulic fluid levels, as a lack of fluid can cause a failure in movement control. Additionally, ensure the tires are inflated to the correct pressure and that no obstructions are blocking movement.

By thoroughly examining these key areas, most mechanical problems can be diagnosed early and corrected before they escalate. Regular maintenance is key to keeping the machine running smoothly for years to come.