When working with machinery, having a clear understanding of each individual element is crucial for proper maintenance and repair. Knowing how various components fit together can save time and prevent unnecessary damage. This section will provide valuable insights into the intricate system of parts that make up your machine.

By carefully studying the structure and function of each component, you can ensure that your equipment operates efficiently. Whether you’re tackling a minor issue or conducting a full maintenance check, a well-structured overview will serve as a helpful tool to identify and address any problems that may arise.

Understanding the John Deere 210 Parts

Maintaining a machine requires a solid grasp of how its individual components function together. Every piece plays a crucial role in ensuring the equipment performs at its best, from the engine to the smallest fastener. Understanding these elements allows for easier troubleshooting and more efficient repairs.

Knowing the layout and purpose of each element helps you quickly identify issues and find the right solution. Each component has a specific role, contributing to the overall performance and longevity of the equipment. A clear overview of how these pieces interconnect is essential for keeping everything running smoothly.

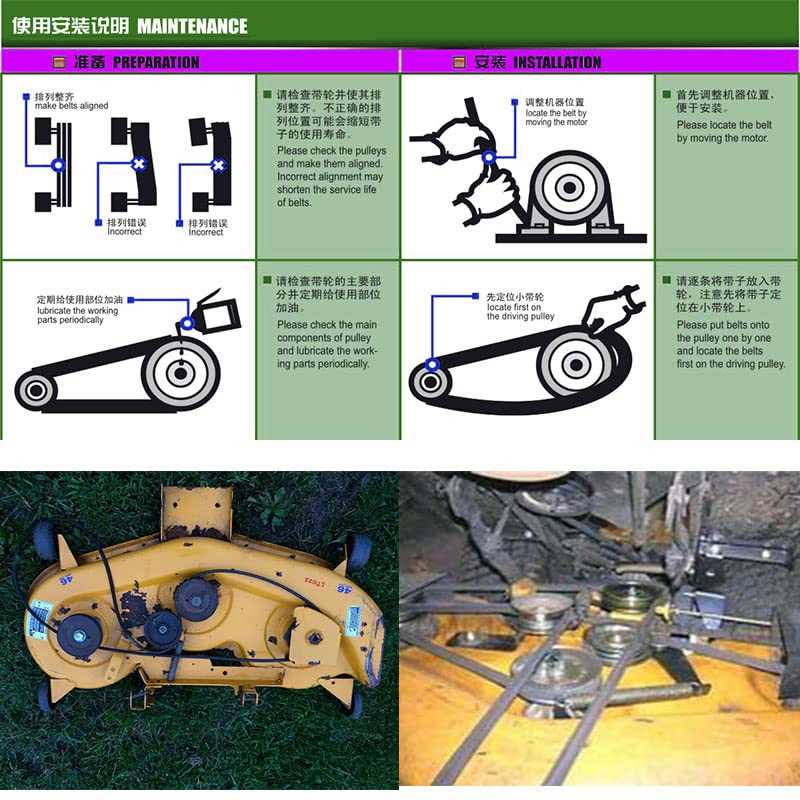

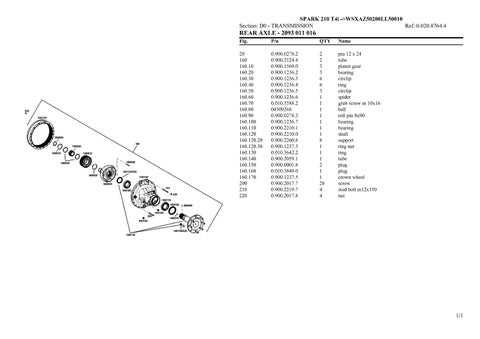

How to Read the Parts Diagram

To efficiently understand how different components of a machine are arranged, it’s essential to know how to interpret technical illustrations. These visual guides offer a detailed view of each part, showing their relationships and placement within the system. Understanding how to read these images can significantly simplify the process of identifying and troubleshooting issues.

These visual representations often use symbols and labels to indicate the position and function of each element. By familiarizing yourself with the layout and learning to correlate the labels with physical components, you can gain a clear understanding of how the system operates and pinpoint specific areas that need attention.

Common Issues and Replacement Parts

Even the most reliable machines can experience wear and tear over time, leading to common issues that require attention. Recognizing these problems early can prevent further damage and ensure the equipment runs smoothly. Understanding which components are prone to failure and knowing how to replace them can save both time and money.

Some of the typical issues encountered include:

- Worn-out belts or pulleys

- Damaged gears and moving parts

- Faulty electrical connections

- Clogged filters or inefficient fuel systems

Knowing which parts need replacement is crucial for effective maintenance. Regularly checking for these common issues and replacing the worn components with high-quality spares will help maintain peak performance.