Maintaining your lawn care equipment is crucial for its longevity and performance. To ensure that your machine continues to function smoothly, understanding its key elements is essential. With the right knowledge, repairs become straightforward, and any issues can be addressed quickly.

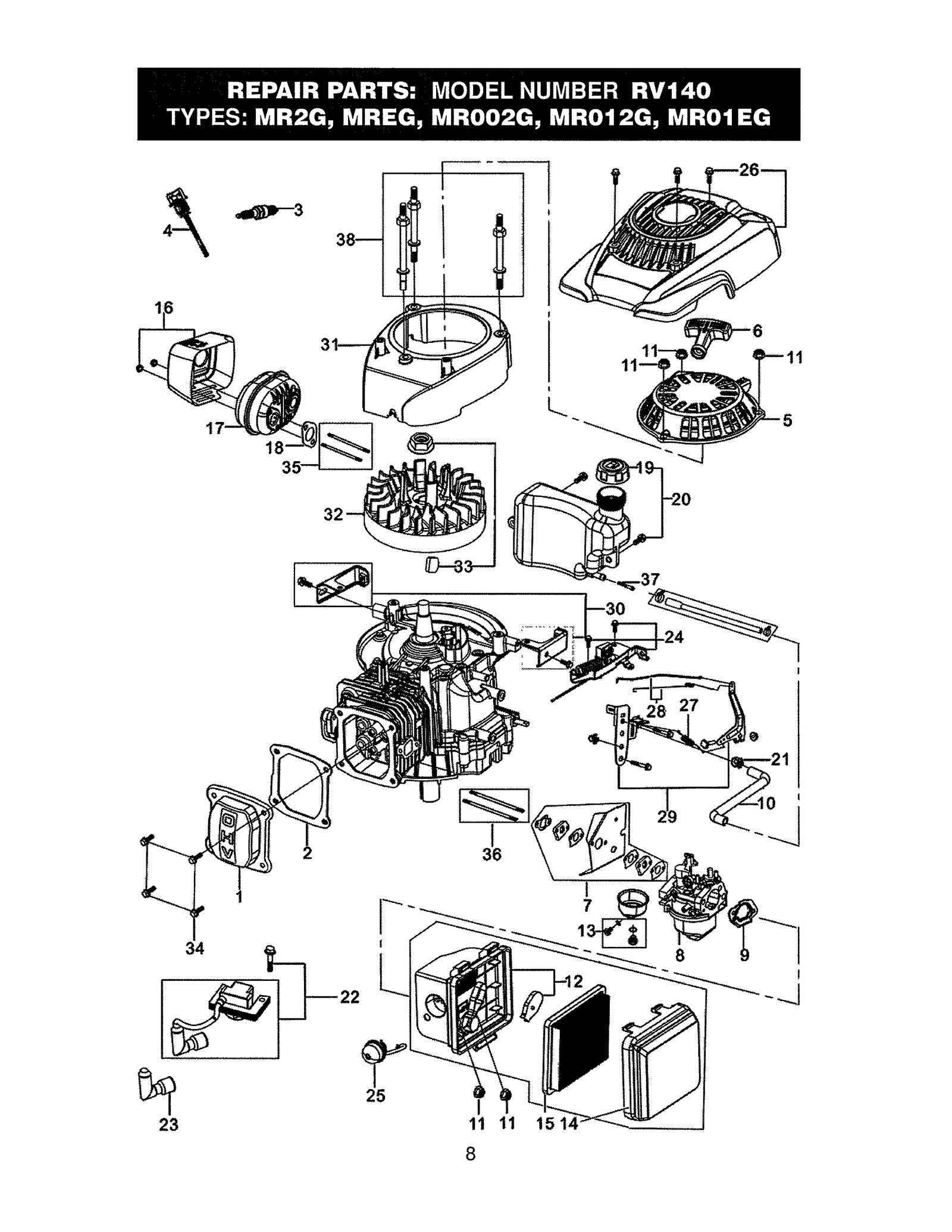

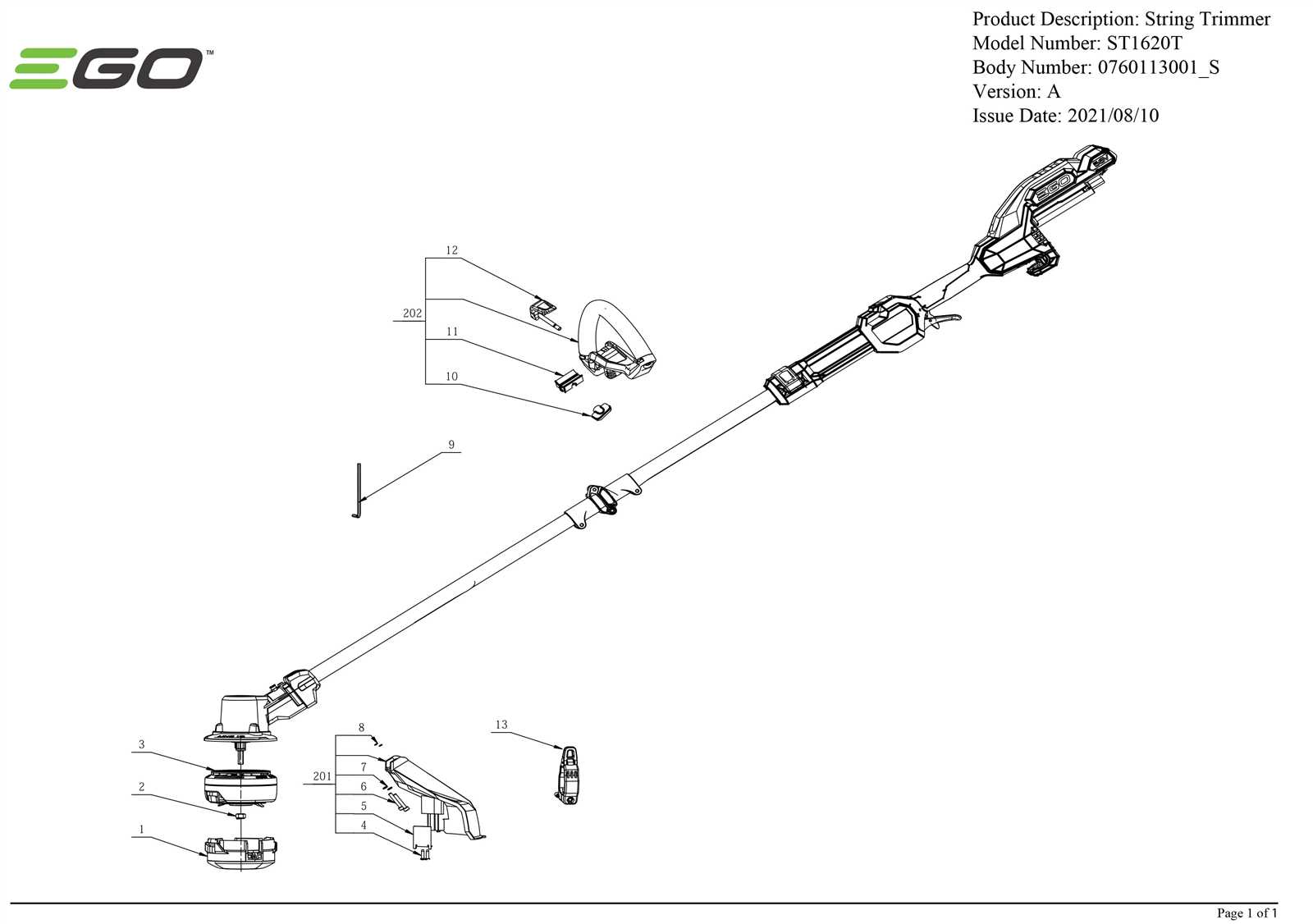

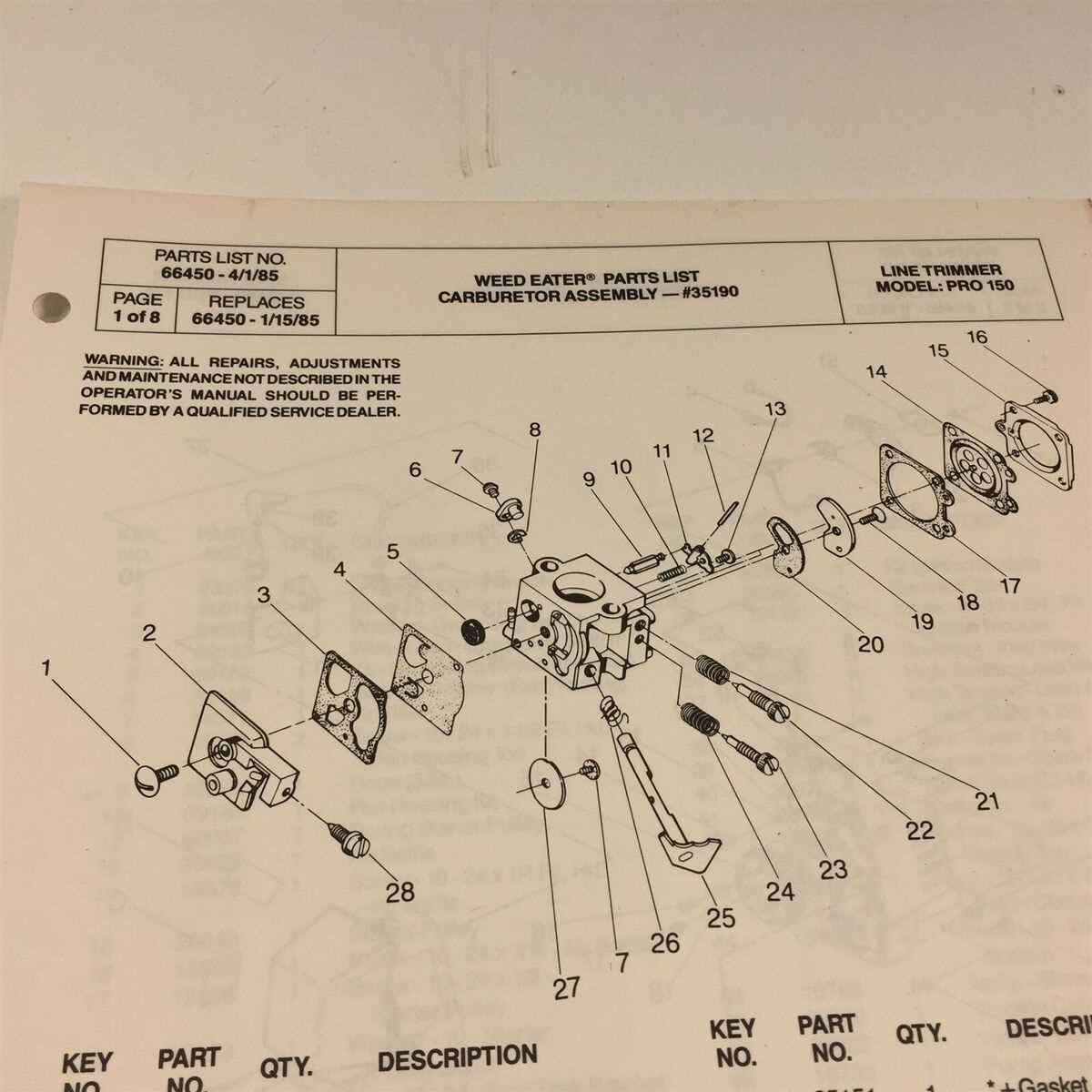

Each tool used for lawn trimming consists of various components that work together to deliver precise results. Familiarizing yourself with these parts and how they interact will help you spot problems and make informed decisions when replacements are necessary. Knowing how to read the schematics of your equipment allows you to identify each element, making repairs and upgrades easier.

Whether you’re dealing with routine maintenance or a breakdown, understanding the internal structure of your machine can save both time and money. By referring to accurate illustrations and part lists, you can ensure that the correct pieces are installed, leading to improved efficiency and performance.

Understanding Lawn Trimmer Components

Every lawn trimming tool consists of several key elements that work in unison to deliver optimal performance. Knowing what these components are and how they function can significantly improve your ability to troubleshoot issues and carry out necessary repairs. By gaining a deeper understanding of the internal structure of your machine, you can address malfunctions with confidence and precision.

The main components typically include the motor, cutting mechanism, handle, and power system, each serving a specific role in ensuring efficient operation. The motor powers the unit, while the cutting mechanism is responsible for the trimming action. The handle allows for precise control, and the power system fuels the engine, making it the heart of the tool. Understanding how these elements work together is essential for effective use and upkeep.

In addition to these basic parts, there are smaller, yet equally important, components such as the safety features, throttle control, and spool that directly impact the tool’s functionality. Being familiar with how these individual elements contribute to the overall performance can help prevent wear and tear, ensuring that your equipment remains reliable over time.

How to Read Lawn Trimmer Schematics

Interpreting schematics for lawn care equipment is an essential skill when performing repairs or maintenance. These visual guides offer a detailed representation of the internal components and their relationships. Understanding how to read these illustrations will help you identify the exact part numbers, configurations, and assembly instructions necessary for effective repairs.

When reviewing the schematic, focus on the different symbols and labels that represent the various components. Each element is typically marked with a unique reference number, allowing you to easily find the corresponding part in a catalog or store. Pay attention to the lines connecting components, as they indicate how the pieces fit together and interact within the system.

It’s also helpful to understand the flow of energy and motion as shown in the schematic. This can clarify how power is transferred through the motor to the cutting mechanism, or how safety features are integrated into the design. Familiarity with these aspects will enable you to make informed decisions about repairs and maintenance, ensuring your tool operates at peak performance.

Common Components for Lawn Trimmer Repairs

When it comes to maintaining your lawn care equipment, there are several common elements that are often subject to wear and tear. Identifying these components and knowing when to replace them can extend the life of your tool and keep it running smoothly. Regular maintenance of these parts ensures reliable performance during use and reduces the likelihood of unexpected breakdowns.

Motor and Power System

The motor and power system are at the heart of any lawn trimmer. Over time, the motor can wear out or suffer damage from prolonged use, requiring replacement. Additionally, issues with the fuel system or battery can lead to poor performance. It is crucial to inspect the motor regularly and ensure that it is functioning optimally to avoid starting issues or loss of power during operation.

Cutting Mechanism and Blades

The cutting mechanism is another area that sees significant wear. Blades, strings, or other cutting tools can become dull or broken after prolonged use, affecting the efficiency of your trimmer. Replacing or sharpening the blades or adjusting the cutting mechanism ensures that the tool continues to provide precise cuts and reliable results. Regular cleaning and maintenance of the cutting components can also help prevent buildup and reduce the need for frequent replacements.