When working with mechanical equipment designed to lift heavy loads, it is essential to have a clear understanding of the internal structure. Each tool is made up of several vital elements that work together to provide stability and performance. Knowing how these components function can help ensure safe operation and improve maintenance practices.

Recognizing the key parts is the first step towards mastering the proper handling and upkeep of such equipment. By examining each section, users can identify potential issues before they become critical, allowing for longer tool life and reducing the risk of malfunction.

Regular inspections and basic knowledge of how these elements interact can help avoid costly repairs. Understanding the design and mechanics behind the lifting process is crucial for anyone using or maintaining this essential equipment in various settings.

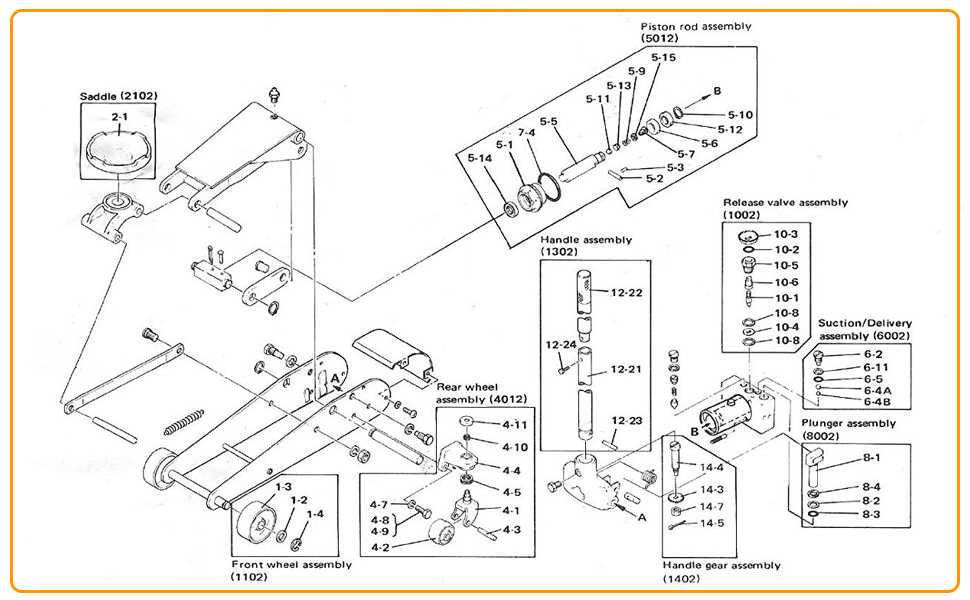

Understanding the Hydraulic Floor Jack Components

To effectively operate any lifting tool, it’s crucial to understand its fundamental structure. The key elements inside this equipment work together to enable smooth operation and ensure safety during use. Each component plays a specific role, from generating force to providing stability and control during the lifting process. Familiarizing yourself with these elements is essential for proper maintenance and efficient operation.

Major Elements of the Lifting Mechanism

- Piston: The central part that creates the lifting force by converting fluid pressure into mechanical force.

- Reservoir: Holds the fluid that powers the system, allowing smooth operation and maintaining pressure.

- Release Valve: Regulates the release of pressure, ensuring the load is lowered gradually and safely.

- Handle: Allows the user to control the lifting and lowering process by applying force to the system.

- Base: Provides stability and support to the entire structure, ensuring safety and balance.

How the Components Work Together

The mechanism relies on the interaction between these parts. As pressure is applied to the fluid within the reservoir, the piston moves, raising the load. The release valve, when activated, gradually releases pressure to lower the object safely. The handle gives the user control over the entire operation, making it easier to manage the lifting process with precision.

Each of these elements must be in good working condition to ensure optimal performance and safety. Regular maintenance and inspection are necessary to detect potential issues early and prevent failures during operation.

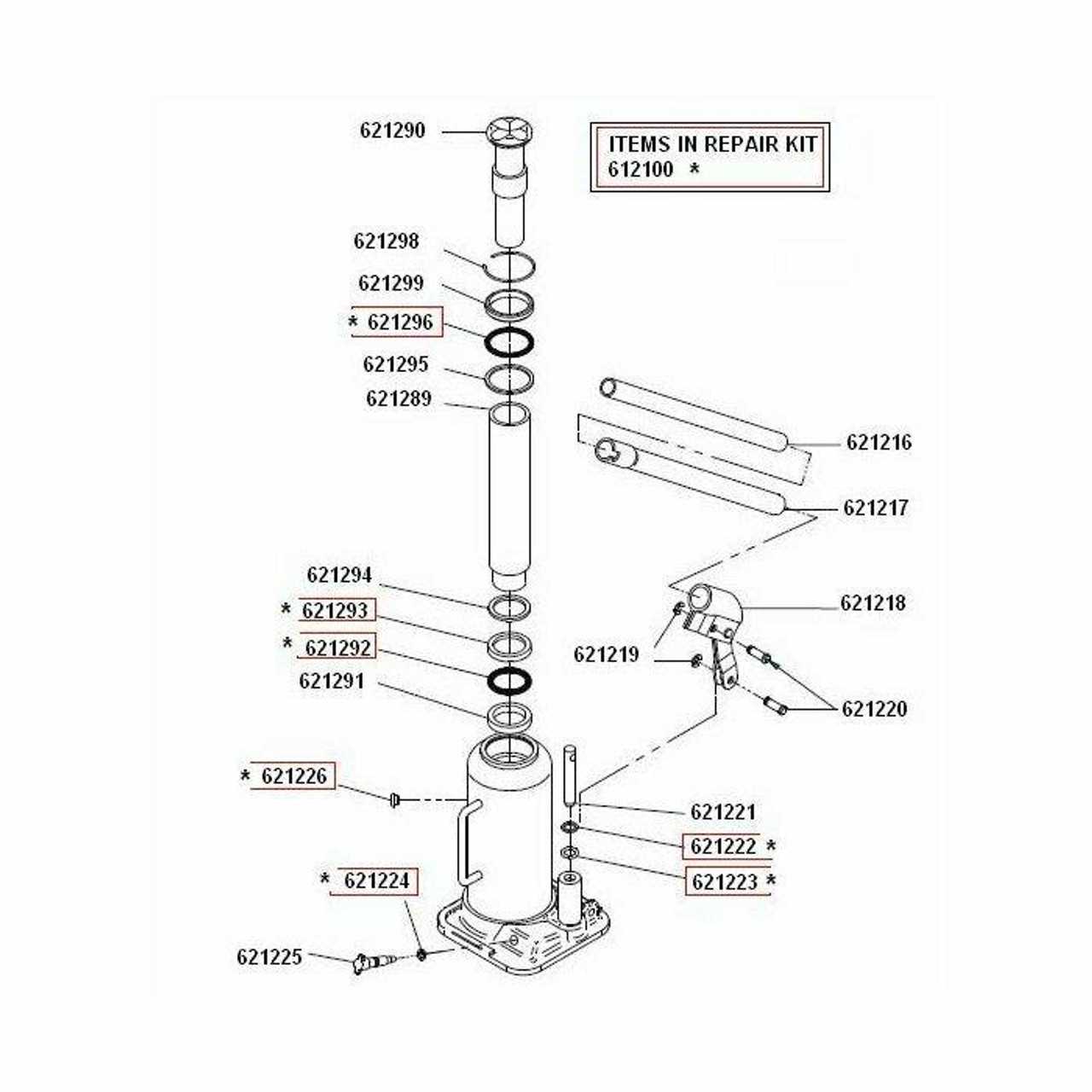

Identifying Key Parts in a 2 Ton Jack

Understanding the main components of a lifting tool is essential for both its operation and maintenance. Each element is designed to perform a specific function that ensures the tool’s effectiveness and safety. By identifying these parts, you can ensure that the equipment is used properly and remains in optimal working condition.

Essential Components of the Lifting Mechanism

- Pump: The mechanism responsible for pushing the fluid, which generates the necessary force to lift heavy loads.

- Release Valve: Controls the gradual lowering of the load by releasing the pressure in a controlled manner.

- Rams: Components that move up and down to support the load, powered by the pressure from the pump.

- Handle: Allows the user to manually apply force to control the operation of the tool.

- Base Plate: Provides the foundation for the equipment, ensuring stability during use.

How to Identify Each Component

Each of these components can be easily identified by their location and function. The pump is typically located at the base and is the first point of contact for the operator. The release valve is usually found near the top, where the pressure can be released safely. The rams are visible during the lifting process, moving up as the load is raised. The handle is attached to the pump, allowing manual control of the entire process.

Regularly checking these components for wear and tear will help you maintain the efficiency and longevity of the equipment. If any part shows signs of malfunction, it’s important to address the issue promptly to avoid damage and ensure continued safe operation.

How to Maintain Hydraulic Floor Jack Parts

Proper maintenance of lifting equipment is essential for ensuring its longevity and reliable performance. Regular upkeep allows the tool to function smoothly and reduces the likelihood of malfunctions. By following a few simple steps, users can keep the components in good condition and prevent costly repairs.

The first step in maintaining the tool is to regularly check the fluid levels. Ensuring there is enough fluid helps the system generate the necessary force and reduces the risk of wear on the internal mechanisms. If the fluid appears dirty or contaminated, it should be replaced to avoid damaging the system.

Next, it is important to inspect the moving components, such as the pistons and rams. These parts should be cleaned periodically to prevent buildup of dirt and debris, which can cause the equipment to function improperly. If any part shows signs of damage or excessive wear, it should be replaced immediately to avoid further damage.

Additionally, the release valve must be regularly tested to ensure it is functioning correctly. The valve should open and close smoothly, allowing for controlled lowering of the load. If it becomes stuck or leaks, it is crucial to repair or replace the valve to maintain safe operation.

Finally, keep the exterior of the equipment clean and free from rust. A clean surface ensures smooth operation and reduces the risk of corrosion, which can compromise the structural integrity of the tool. Regularly inspect the base and handle to make sure they are firmly attached and free from damage.