Proper maintenance of outdoor machinery relies heavily on understanding the individual elements that contribute to its functionality. Each piece plays a crucial role in ensuring optimal performance and longevity. Having a clear grasp of how each component interacts will allow you to troubleshoot effectively and make informed decisions when repairs or replacements are necessary.

Whether you’re a seasoned professional or a novice, having a visual reference of the various parts of your machinery can significantly enhance your repair and upkeep skills. Recognizing these elements and knowing their specific functions is the key to achieving a well-maintained and efficient machine. With this guide, you’ll become more confident in identifying and addressing issues that may arise during operation.

Understanding Lawn Equipment Components

Effective operation and care of any outdoor machinery depend on understanding the critical elements that enable it to function properly. Recognizing the individual components allows users to troubleshoot, perform maintenance, and make necessary repairs efficiently. Each part works in harmony to ensure smooth operation, and knowing their functions helps extend the equipment’s lifespan.

Key Functional Elements

The primary components of this equipment include the motor, drive system, and cutting mechanism, all of which are essential for efficient operation. The motor generates power, while the drive system transfers that power to the cutting blades, allowing the machinery to perform its intended task. Understanding how each part contributes to the overall performance ensures better maintenance and more effective usage.

Maintenance and Replacement Considerations

Regular inspection and maintenance of these critical components prevent wear and tear, ensuring that the equipment operates at its best. Some parts may require periodic replacement due to exposure to the elements or general use. Familiarity with the function of each element and its condition over time will help identify when a part needs attention or replacement.

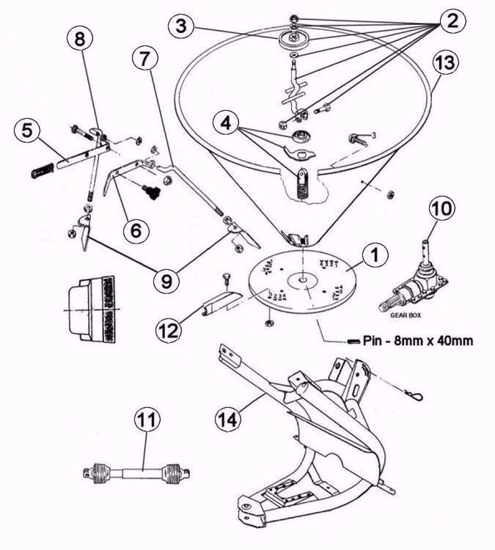

Identifying Key Parts in the Diagram

Understanding the layout of essential components within outdoor machinery is crucial for effective maintenance and troubleshooting. A visual guide of these elements offers valuable insight into their placement and function. Recognizing each piece helps with quicker identification of potential issues and ensures that repairs or adjustments are made accurately.

Main Power Source and Drive Mechanism

The power source is typically located at the heart of the machine, providing the energy necessary for all operations. It’s important to understand its connection to the drive system, which transfers power to the cutting or movement mechanisms. In most equipment, these two parts are central to the entire operation, and failure in either component often impacts overall performance.

Cutting and Operational Systems

The cutting system is typically composed of blades, spindles, and other mechanisms responsible for trimming or shaping. These components interact with the drive system to ensure smooth, effective operation. Regular inspection of these parts is necessary to avoid damage and maintain efficiency, especially since they endure considerable stress during usage.

Maintenance Tips for Longevity and Performance

Proper care and regular maintenance are essential for ensuring the continued effectiveness and durability of outdoor equipment. By following best practices, users can prevent unnecessary wear, avoid costly repairs, and extend the lifespan of their machines. A proactive approach to maintenance helps maintain peak performance, even during heavy usage.

Regular Inspections and Cleaning

Inspecting your equipment regularly is one of the most effective ways to prevent unexpected failures. Ensure all components are secure, clean, and free from debris. Pay close attention to moving parts, such as the drive system and cutting elements, which are prone to wear. Cleaning after each use can help prevent buildup that may affect functionality, especially in areas exposed to dirt and moisture.

Lubrication and Component Replacement

Proper lubrication is crucial for reducing friction between moving components. Regularly applying the right type of lubricant helps prevent overheating and prolongs the life of parts. Additionally, replacing worn-out elements, such as belts or blades, ensures the machinery operates at peak efficiency. Neglecting these tasks can lead to costly repairs or diminished performance.