Every cutting tool is made up of several interconnected elements, each playing a vital role in its functionality. Whether you are working with a mechanical tool for tree felling or general maintenance, knowing how these elements work together ensures optimal performance and safety.

The precision of these components directly influences the efficiency and longevity of your equipment. A deep understanding of their design and operation allows for better care, easier troubleshooting, and effective repairs when needed. Proper maintenance is crucial to ensure the tool operates smoothly and does not fail during critical tasks.

In this guide, we will break down the structure of these essential elements, focusing on their unique roles and how they collaborate to make the tool effective. Whether you are a novice user or an experienced technician, having a clear understanding of these parts is key to maximizing your equipment’s potential.

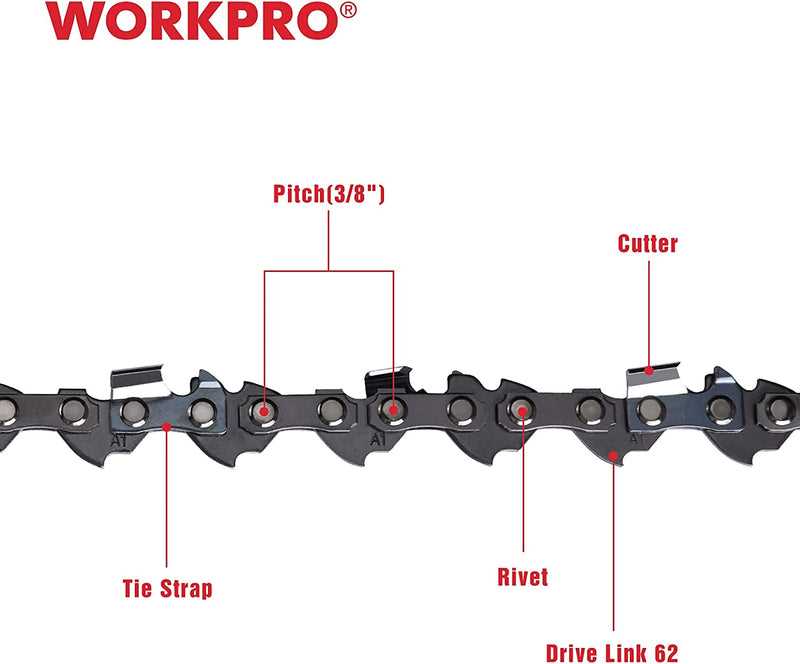

Understanding Chainsaw Chain Components

Effective cutting tools consist of various elements, each designed to perform a specific function that contributes to the overall operation. These components work in unison to ensure smooth and efficient cutting, whether you’re tackling thick logs or performing lighter tasks. To optimize performance and extend the tool’s lifespan, understanding the roles of each piece is crucial.

Main Functionality of Each Element

At the core of any cutting system, the main components include those responsible for gripping, moving, and cutting the material. These elements work together to ensure precision, speed, and efficiency. Without one or more of these pieces, the system’s operation could be compromised, leading to poor performance or even equipment failure. Regular maintenance of each part is essential for preserving these functions and achieving the desired cutting results.

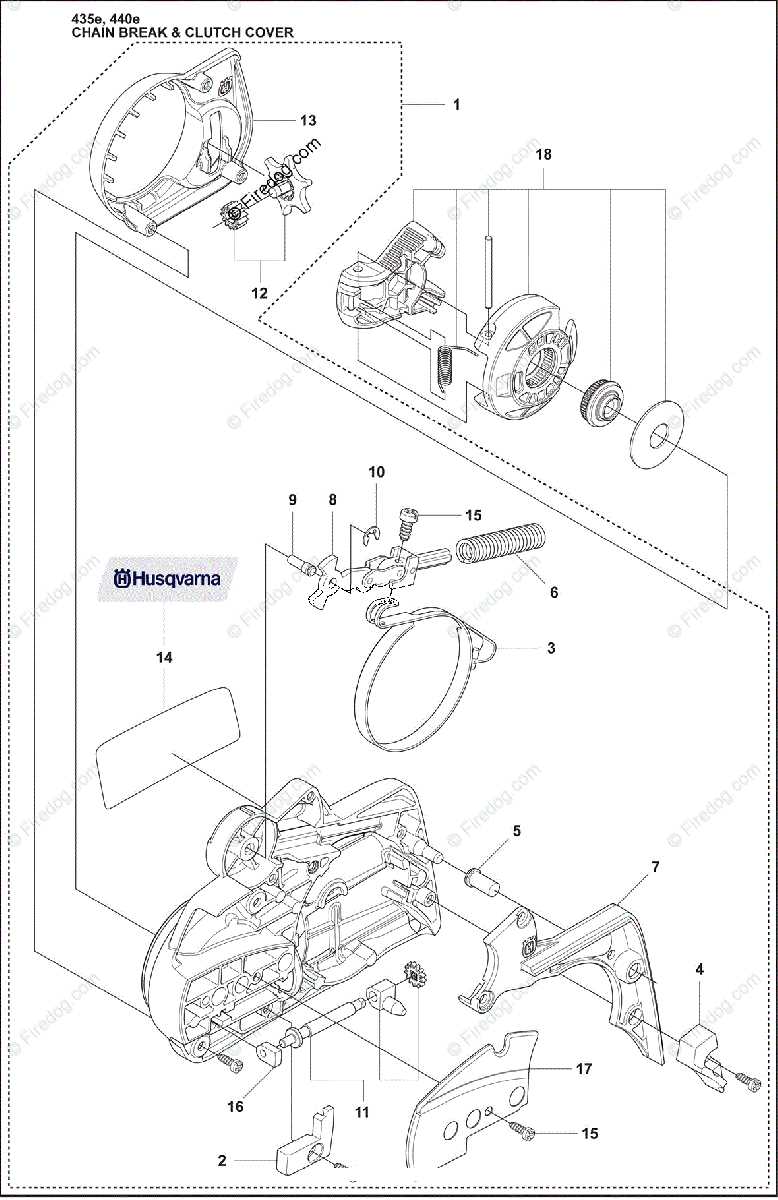

How Components Interact for Maximum Efficiency

Every part is designed to complement others, with each fulfilling a distinct role. Some elements are primarily responsible for power transmission, while others are involved in the movement of the tool itself. Understanding the interdependence of these components will help users make informed decisions regarding maintenance and troubleshooting, ensuring that all elements continue to perform at their peak potential.

How Chainsaw Chain Parts Work Together

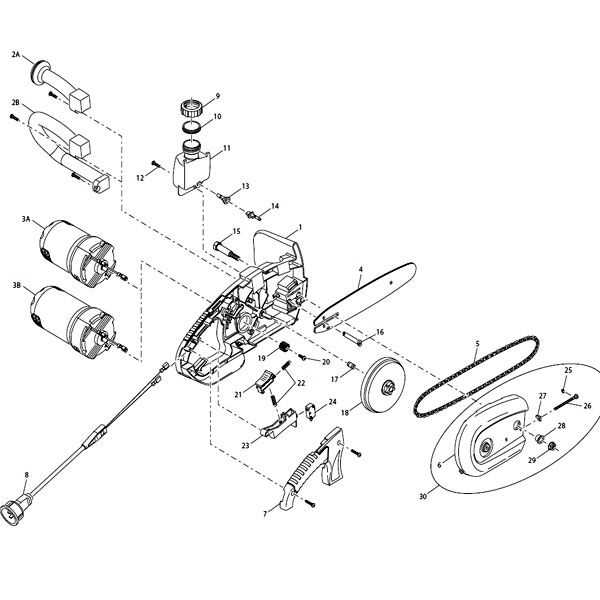

For any cutting tool to operate efficiently, its components must work in harmony, each fulfilling its specific function. The seamless interaction between elements such as the driving mechanism, the gripping surface, and the cutting edge is what allows the tool to perform its tasks effectively. If any one part fails to function properly, it can cause a chain reaction that affects the overall performance.

The motor generates power that is transferred to the elements responsible for movement and cutting. These components must work together to transfer the force smoothly, ensuring the tool remains effective throughout its operation. Additionally, the design of each piece ensures that the tool can maintain consistent speed and precision during use, while also providing control and safety to the user.

Understanding how these elements interrelate helps users maintain the tool, troubleshoot issues, and make informed decisions about repairs. Proper maintenance ensures that all components continue to function at their best, preventing premature wear or failure that could impact performance.

Maintaining Your Chainsaw Chain for Longevity

Proper care and maintenance of your cutting tool are essential for extending its lifespan and ensuring it performs at its best. Regular upkeep of the individual components prevents wear and tear, reduces the risk of malfunction, and keeps the tool working efficiently for longer. By following a few simple maintenance steps, you can help preserve the quality of the tool and avoid costly repairs.

Cleaning and lubricating the moving parts are crucial to preventing friction and overheating. Additionally, ensuring that all components are securely attached and functioning correctly can help avoid damage during use. Sharpening the cutting edges periodically ensures smooth operation and allows the tool to cut through materials with minimal effort. Checking for any signs of damage or wear, and replacing worn-out components promptly, will also help prevent further issues.

Adopting these maintenance practices will not only improve the tool’s performance but will also allow it to serve you reliably for many years. Regular inspection and timely servicing are key to maintaining optimal functionality and avoiding unnecessary repairs or replacements.