Understanding the structure and functioning of agricultural machines is crucial for effective maintenance and smooth operation. This section explores the key components found in modern machinery used for harvesting and crop management. With a clear understanding of the different parts, operators can troubleshoot, replace, and maintain their equipment more efficiently, ensuring long-lasting performance.

Key Elements of Harvesting Machinery

Farm machines consist of various mechanical elements working together to perform complex tasks. From the feed mechanism to the press and collection system, each part has a unique role. Identifying and understanding these components is essential for any farmer or technician to ensure the machine operates at its optimal level.

Feed System and Handling

The feed system is responsible for pulling material into the machine for processing. It includes rollers, belts, and tines that work together to direct the crop towards the processing area. Regular checks for wear and tear in these components can prevent clogs and downtime.

Compression Mechanism

The compression section of the machinery ensures that material is compacted effectively. It consists of heavy-duty rollers and a piston system, which exert pressure to form uniform bales. Keeping these components well-lubricated is critical for smooth operation.

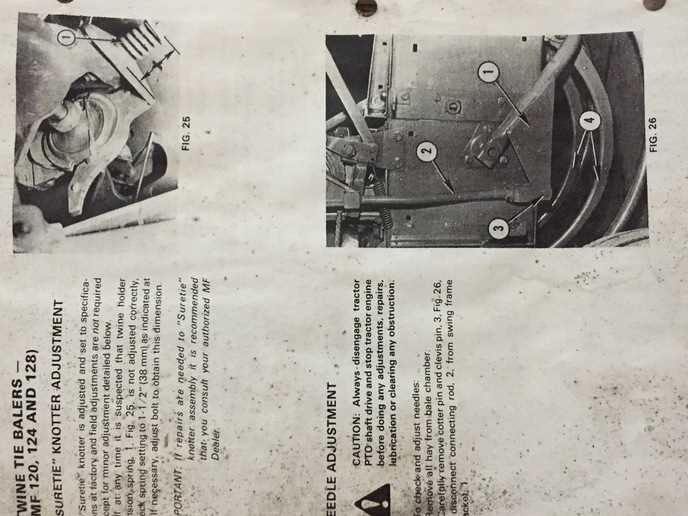

Maintaining Your Equipment

Proper upkeep is key to extending the life of any agricultural machine. Regular inspection and maintenance of the mechanical systems involved can prevent costly repairs and improve operational efficiency. It’s important to regularly replace worn-out components and clean the machinery after each use to avoid build-ups that could lead to performance issues.

Checking for Wear and Tear

- Belts and Chains: These should be checked for tension and cracks regularly.

- Rollers: Ensure rollers are free from damage and adequately lubricated.

- Hoses and Seals: Inspect for leaks or deterioration that could affect hydraulic pressure.

Replacing Worn-Out Parts

When certain parts wear down, it’s essential to replace them promptly to avoid additional damage. Using genuine replacement components guarantees compatibility and reliability, ensuring the machine continues to operate as intended.

Regular Cleaning

After each use, it’s important to clean the machine thoroughly. Dirt and debris can cause parts to malfunction, and a buildup of material can lead to overheating. Proper cleaning helps prevent such issues and keeps the system functioning at peak performance.

Understanding the Agricultural Machinery Model

Essential Components of Harvesting Equipment

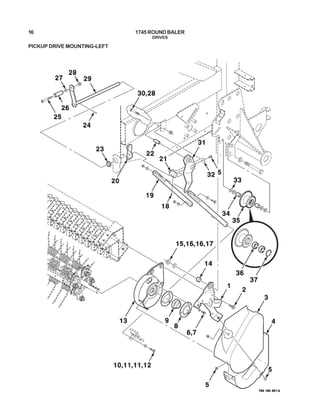

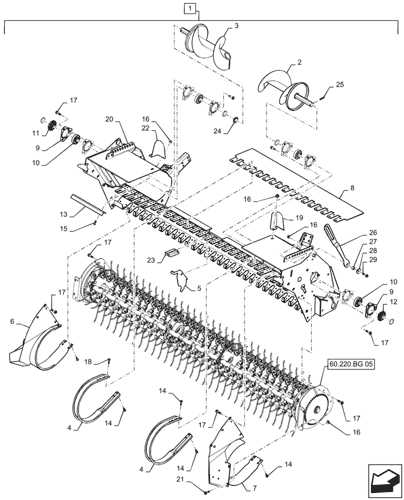

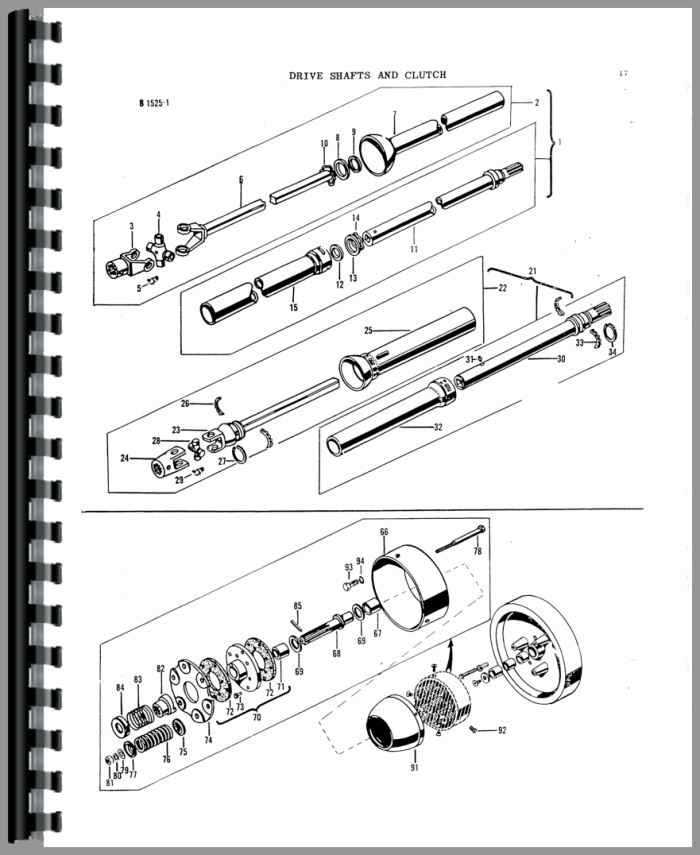

How to Interpret the Component Chart

Identifying Key Elements and Functions

Maintaining Your Farming Machinery

Proper understanding of agricultural machinery is fundamental for maximizing its efficiency and lifespan. In this section, we’ll explore the main components of a harvesting machine, their individual roles, and how to effectively maintain the system. With the right knowledge, operators can identify problems early and perform necessary repairs, ensuring consistent operation throughout the harvest season.

Every machine consists of several core elements that contribute to its functionality. These include mechanisms for gathering, compressing, and discharging materials. Familiarity with each part allows you to recognize how they interact and what needs to be maintained or replaced over time. Understanding these key components is essential for troubleshooting and overall machine care.

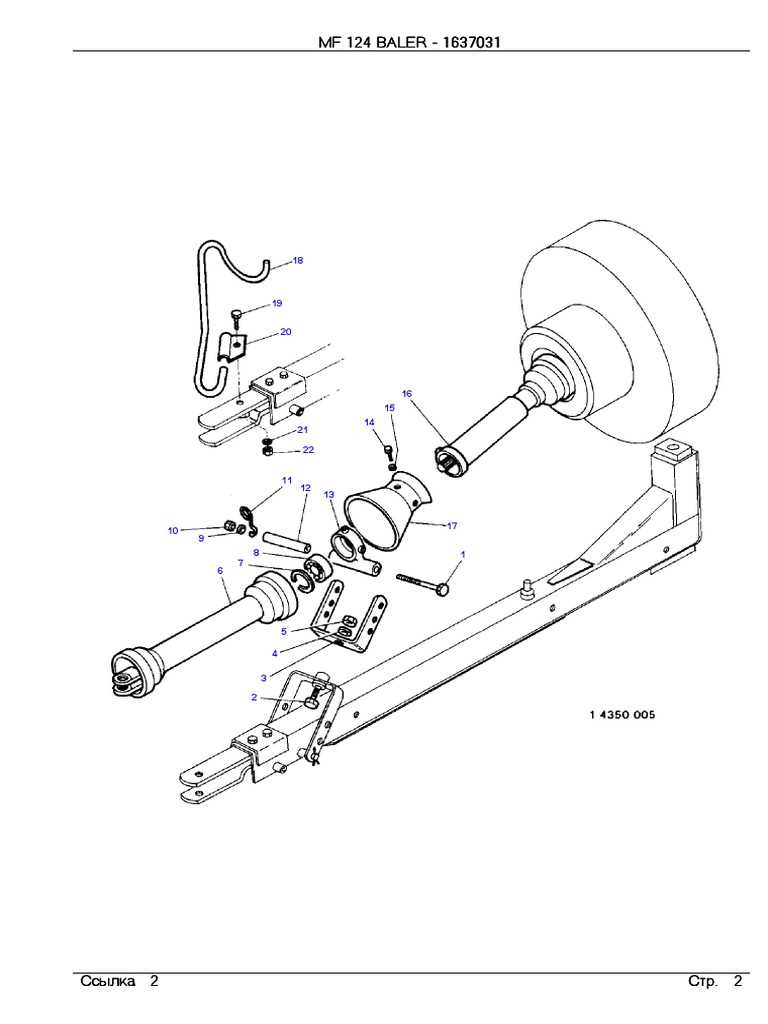

Reading a component chart is a crucial step in maintaining and repairing farm equipment. Such a chart serves as a visual guide to each part’s location and its specific function. By referencing this diagram, operators can identify any worn-out or damaged parts and address them efficiently before they lead to major malfunctions.

Key elements such as rollers, belts, and collection mechanisms play a major role in the machine’s operation. Regular inspection of these parts is necessary to avoid breakdowns. Identifying the role of each part will make it easier to spot potential issues and take the necessary actions to prevent further damage.

Routine maintenance is essential to ensuring the longevity and performance of any farming machine. Regular checks for wear, cleaning, and lubrication are necessary to avoid excessive strain on mechanical systems. Well-maintained equipment leads to smoother operations and less downtime, ultimately enhancing productivity during harvest seasons.