When it comes to maintaining your equipment, understanding its internal structure is key. Whether you’re troubleshooting or performing regular upkeep, knowing how each component functions ensures a smoother operation. A clear and detailed view of the system helps users identify potential issues before they become serious problems.

By exploring the key elements and their connections, you can easily locate any malfunctioning parts. Regular inspections and knowing where to look for wear and tear will keep your machine running efficiently for longer periods. A proactive approach to care can save both time and money, extending the life of your tool.

In this guide, we’ll walk you through everything you need to know, from identifying each crucial element to maintaining your gear for optimal performance. With proper knowledge, you’re equipped to handle any necessary repairs or replacements.

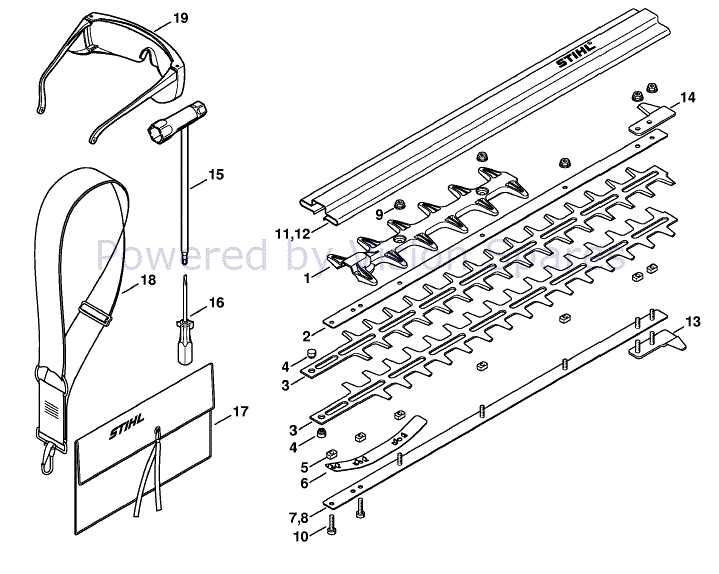

Understanding the HL 94 K Components

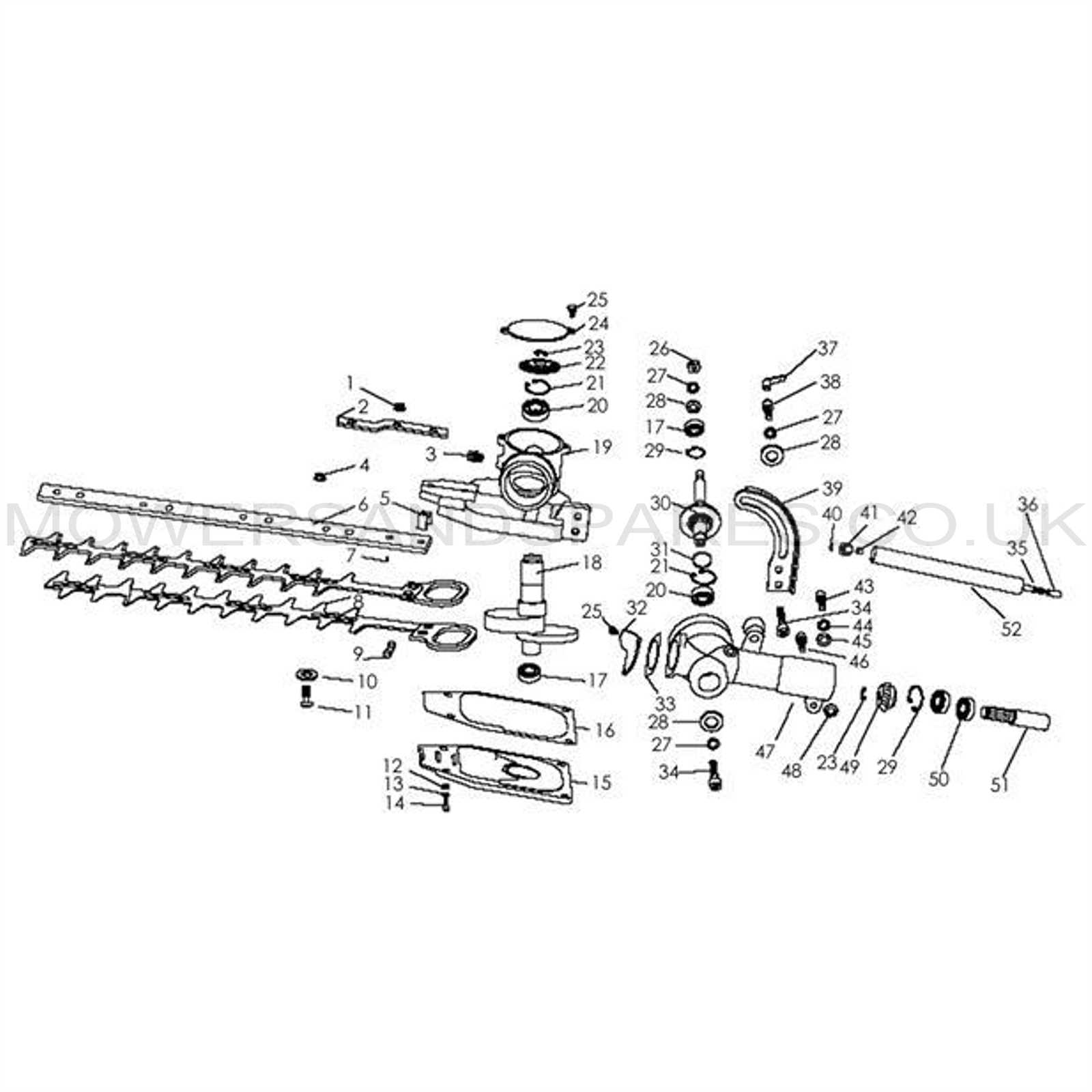

To properly maintain and troubleshoot your equipment, it’s essential to familiarize yourself with the various elements that make up the machine. Each individual component plays a specific role in ensuring the overall functionality of the tool. Recognizing how these pieces interact helps users assess the condition and performance of their equipment with ease.

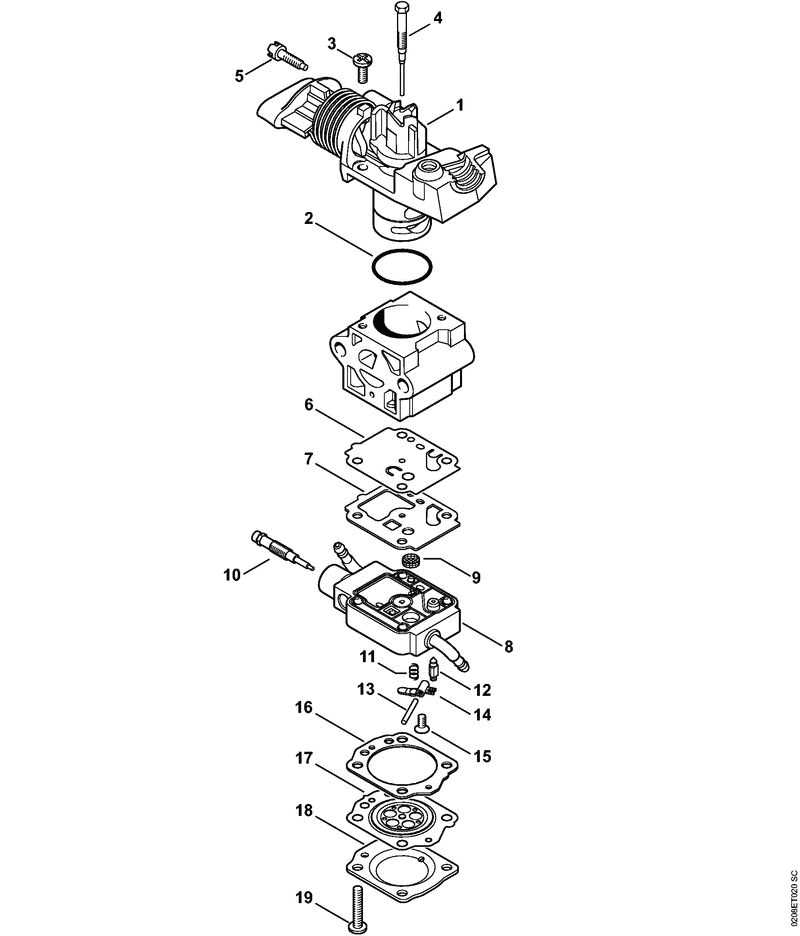

Key sections of the device include the engine system, handle assembly, and cutting mechanism. These major areas are interconnected, and understanding how each part works within the system allows for better decision-making when it comes to repairs or replacements. The engine, for example, drives the tool’s power, while the cutting mechanism directly affects performance and efficiency.

By recognizing the most important components and their functions, you are better prepared for preventive care. Regular checks and awareness of where each part is located and how it contributes to the machine’s performance can prevent breakdowns and increase the device’s lifespan.

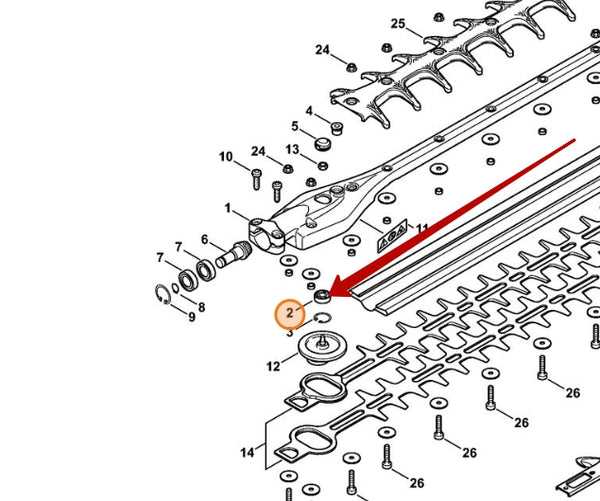

How to Read the Parts Diagram

Understanding how to interpret a visual breakdown of your equipment’s structure is crucial for efficient maintenance. A clear illustration of the tool’s components offers valuable insight into its construction, helping you identify each section and how they fit together. This guide will show you how to read and make use of these schematics to diagnose and fix issues effectively.

Identifying Key Elements

The first step in reading a schematic is to familiarize yourself with the symbols and labels used to represent the various parts. Each component is usually numbered or marked, and these numbers correspond to detailed descriptions. Take note of the key symbols that show how the elements interact, which will allow you to pinpoint problems quickly.

Locating Specific Sections

Once you understand the symbols, you can begin to focus on specific sections of the tool. Often, illustrations are divided into segments, such as the engine or cutting mechanism, to make it easier to locate the exact part that may need attention. By following the lines and numbers, you can trace the flow of the system and identify where issues may arise.

Essential Tips for HL 94 K Maintenance

Regular care and timely inspections are essential for keeping your equipment in top condition. Preventive maintenance not only extends the lifespan of the tool but also ensures its performance remains at an optimal level. By following a few key practices, you can avoid common issues and reduce the need for costly repairs.

One of the most important maintenance tasks is to regularly clean the tool after use. Removing dirt, debris, and other residues helps prevent clogs and ensures smooth operation. Pay special attention to the cutting mechanism and the engine area, as these are the parts most prone to wear and tear.

Additionally, always check for signs of loose or damaged components. Tighten screws, bolts, and other connections as needed. This simple check can prevent more serious problems from developing. Regular lubrication of moving parts is also critical to maintain proper function and reduce friction.