Having a clear understanding of the internal workings of any mechanical equipment is crucial for ensuring smooth performance and longevity. This knowledge allows users to troubleshoot, replace worn-out parts, and perform necessary maintenance efficiently.

In this section, we explore the various elements that make up a powerful hydraulic machine designed for heavy-duty tasks. By identifying each component and its function, users can better navigate the repair and maintenance process.

Proper knowledge of these mechanisms empowers individuals to manage their machinery with confidence, avoiding costly errors and enhancing the lifespan of their equipment.

Understanding the Key Components of a Hydraulic Machine

When working with heavy-duty machinery designed for splitting large pieces of wood, it is essential to have a thorough understanding of the different components involved. These components work together to ensure that the system operates smoothly, safely, and efficiently. Familiarizing yourself with these parts helps in maintaining the equipment and identifying any issues that may arise during use.

Hydraulic System and Its Role

The hydraulic system is the powerhouse of any machine designed for tough tasks. By converting fluid pressure into mechanical force, it powers the critical functions needed for splitting. This system consists of various parts such as pumps, valves, and hoses that direct the fluid to specific areas to create the necessary force. Regular inspection and maintenance of the hydraulic system are crucial to prevent leaks or failures.

Structural Frame and Operational Mechanics

The frame of the machine provides the necessary support and stability for the entire system. It holds the hydraulic components in place and ensures that all movements are precise and controlled. Additionally, the operational mechanics include the moving components like the wedge and the ram, which are responsible for the actual splitting action. A well-maintained frame and these moving elements are vital to ensure safe and effective operation.

Having a solid understanding of the internal mechanisms allows users to troubleshoot issues and perform repairs with greater ease. Regular upkeep of these components ensures the machine remains in optimal working condition, reducing downtime and increasing productivity.

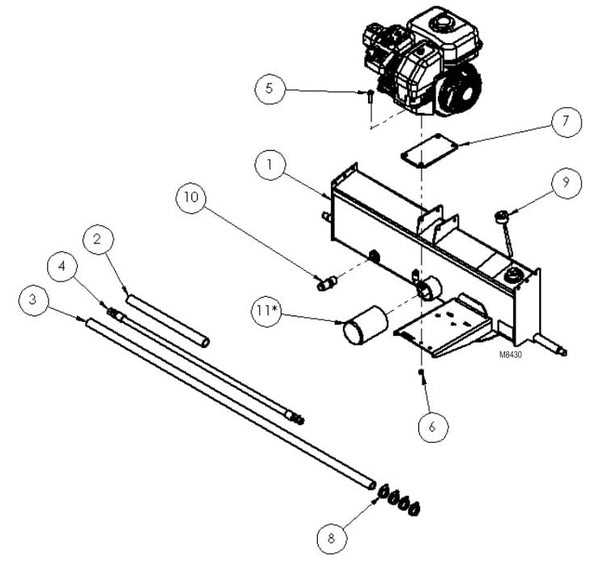

How to Read the Parts Diagram Effectively

Understanding how to interpret an equipment illustration is an essential skill when performing maintenance or repairs. These diagrams visually represent the various components, providing a clear layout of how everything fits together. Learning to read these visuals accurately helps users identify the right components and determine where adjustments or replacements are needed.

Start by familiarizing yourself with the overall layout of the diagram. Pay close attention to the labels and numbers that correspond to each component. These references are typically found next to each item, allowing you to cross-check with the parts list. This step will help in identifying the specific parts and understanding their roles within the system.

Next, identify any symbols or notations used in the diagram. These can indicate various conditions or functions, such as movement or specific directions for assembly. Understanding these markings will give you a deeper insight into the operation of the equipment, making the repair or maintenance process much more efficient.

Once you’ve become comfortable with the basic structure of the illustration, it becomes easier to navigate complex machinery setups. Knowing how to read these visual guides enables you to confidently replace, adjust, or repair specific elements with minimal effort.

Maintaining Your Hydraulic Equipment

Proper maintenance is key to ensuring the longevity and optimal performance of any heavy-duty machinery. Regular care helps avoid breakdowns, enhances efficiency, and extends the lifespan of your equipment. By staying proactive with maintenance, you can ensure that all moving parts function smoothly and safely.

Start by regularly checking the hydraulic system for any leaks or signs of wear. Keep the fluid levels within the recommended range and replace the fluid at intervals specified by the manufacturer. Inspect hoses and connectors for any damage or loose fittings to prevent operational failures.

The structural frame and moving components should also be part of your routine inspection. Look for any cracks, rust, or deformation in the frame. The moving parts, including the wedge and ram, should be lubricated to reduce friction and prevent premature wear. Ensuring these parts are in good working condition is vital to the overall performance of the machine.

In addition to mechanical inspections, always check the safety features of the equipment. Ensure that all safety guards and switches are in place and functioning properly. Keeping your equipment clean and free of debris will also help maintain its efficiency and reduce the likelihood of malfunction.