Proper maintenance and repair of equipment require a solid understanding of its internal structure and individual parts. Whether you’re a seasoned technician or a DIY enthusiast, having a clear reference for identifying and replacing key components is essential. A detailed visual guide can be an invaluable resource in this process, offering clarity and precision when working with complex machinery.

Effective repairs depend on knowing how each piece interacts with the others. A well-structured chart or reference can simplify the process of locating faulty parts and ensure you have everything you need to restore functionality. By understanding the layout and function of various elements, you can avoid mistakes that might lead to further damage or inefficiency.

Taking the time to learn the system’s design can significantly improve both the speed and accuracy of repairs. Whether it’s for routine maintenance or fixing specific issues, having the right tools and knowledge will enhance your overall experience. A clear understanding of how to read and utilize these references is key to achieving successful outcomes in every project.

Understanding the Mechanical Components

When working with complex machinery, it’s essential to comprehend the individual elements that make up the system. Each component plays a unique role in the overall functionality and performance. Familiarizing yourself with these pieces allows for more efficient troubleshooting and maintenance, ensuring the equipment operates at its best. A well-organized reference can aid in identifying each part and understanding how it contributes to the whole setup.

To maintain or repair equipment effectively, you must be able to recognize the functions of various internal mechanisms. From the power system to the minor connectors, each part needs to be assessed for wear and potential issues. With a clear understanding of the structure, you can avoid unnecessary disassembly and focus on the specific areas requiring attention.

Knowledge of how components interact within the system can also help in the selection of replacement items. Understanding their arrangement and relationship provides the confidence needed to carry out repairs without causing additional complications. A comprehensive guide ensures you have the information needed for any maintenance task.

How to Interpret the Visual Reference

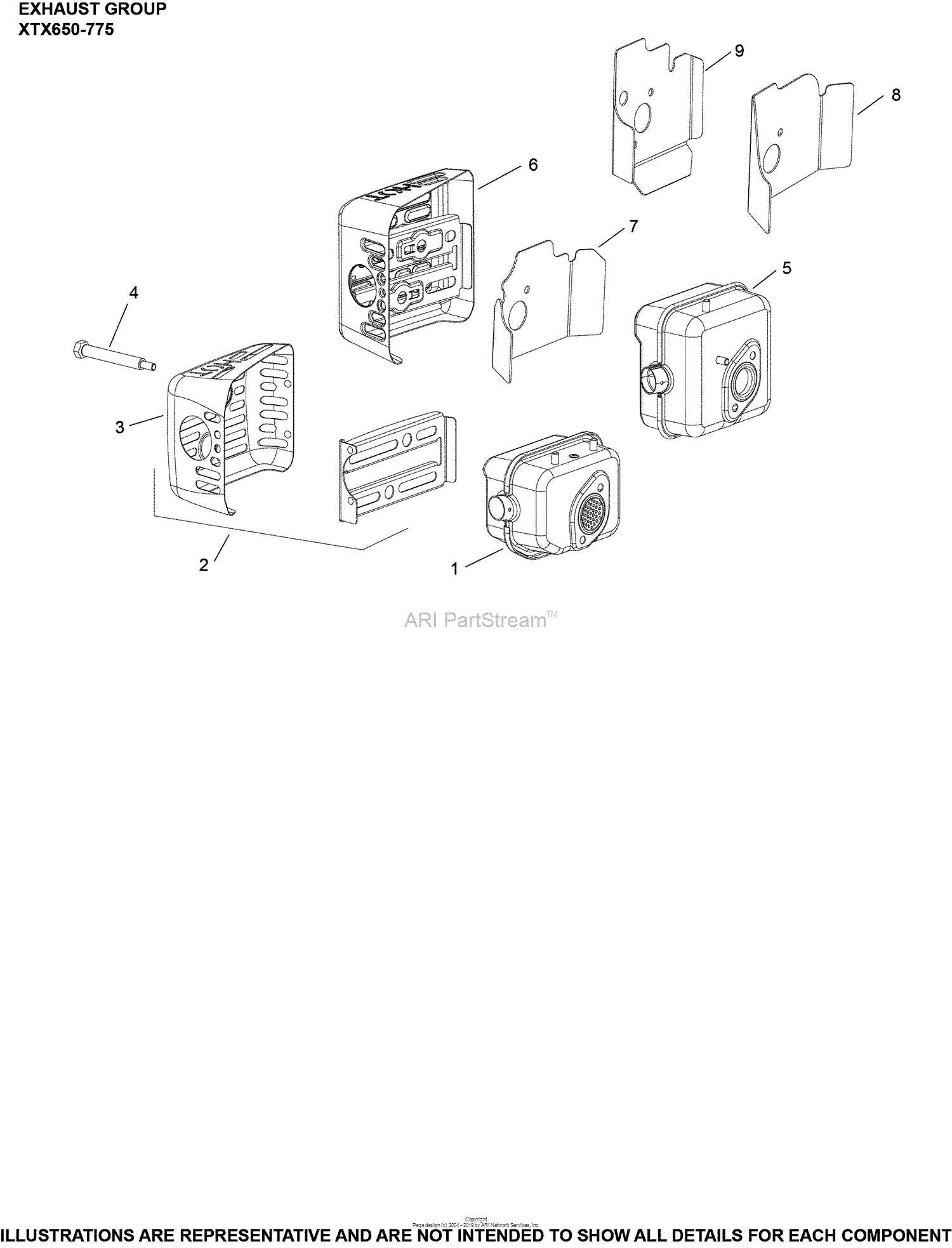

Understanding a detailed visual guide is crucial for effectively navigating the inner workings of any machinery. These illustrations provide a clear layout of the system’s components, helping to pinpoint the exact locations of each part. Interpreting this reference requires careful attention to the labeling and connections shown, ensuring that each piece is correctly identified and understood in its function within the system.

Start by focusing on the main assembly and the way different elements are arranged. The visual guide typically organizes the components in a way that reflects their physical placement, making it easier to trace their connections and understand their role in the overall operation. Key features like numbers, labels, and arrows can help clarify the relationships between parts and guide you through the repair or maintenance process.

It’s also important to familiarize yourself with any codes or symbols used in the reference. These are often standardized to indicate specific attributes of the parts, such as size, type, or material. By knowing how to read these markers, you can quickly determine which elements require replacement or attention, streamlining the maintenance process.

Tips for Replacing Mechanical Components

Replacing faulty elements in machinery requires precision and care to ensure the system functions as intended. Following the right steps can prevent further damage and help maintain the longevity of the equipment. It’s essential to be prepared with the correct tools, knowledge of the components, and an understanding of the overall structure before beginning any replacement task.

Prepare Before Starting

Before removing any components, it’s crucial to make sure that the equipment is powered off and properly secured. Take note of the layout and make sure you have the right replacement items on hand. Double-check compatibility to ensure that the new part will fit correctly, avoiding any potential issues during installation.

Handle with Care

When replacing a component, handle each part carefully to avoid causing any damage to surrounding areas. It’s also a good practice to clean the area around the part before installing the new one, as dirt or debris can interfere with proper functioning. Follow the manufacturer’s instructions for securing the new component, ensuring all connections are tight and properly aligned.