When maintaining heavy machinery, it is essential to have a clear understanding of each individual element and its role in the overall operation. Proper knowledge of how each component interacts ensures effective repairs and routine upkeep. By visualizing the structure and understanding the function of each part, operators can more easily identify issues and plan maintenance tasks.

Identifying and maintaining these elements requires familiarity with their placement and connection within the entire system. Without this clarity, addressing malfunctions or making replacements can become a challenging and inefficient process. Utilizing visual resources can provide significant advantages in achieving a smoother workflow and more precise diagnostics.

Effective use of diagrams can be a game-changer, simplifying the complex task of tracking down specific components. Knowing where each part fits within the machine’s framework saves time and effort, making it possible to avoid common repair mistakes and ensure optimal performance over time.

Understanding 70 Series Heavy Equipment Components

Effective operation and maintenance of heavy machinery depend on a comprehensive understanding of the various elements that make up the machine. Each component, from the engine to the hydraulic systems, plays a vital role in ensuring that the equipment functions smoothly. Recognizing the purpose of each part and its connection to others helps operators maintain high performance and address any issues that arise.

Critical Mechanical Systems

The primary systems involved in the machine’s function include the powertrain, hydraulic system, and structural framework. These systems work together to allow for efficient movement and material handling. Understanding how they interact and recognizing common failure points can significantly reduce downtime and repair costs.

Hydraulic and Structural Components

The hydraulic system plays an integral role in powering various functions, such as lifting and tilting mechanisms. The strength and efficiency of the structural components ensure stability and longevity under heavy loads. Regular maintenance and monitoring of these systems can prevent costly repairs and enhance overall durability.

Key Components of 70 Series Heavy Equipment

Understanding the critical components of heavy machinery is essential for efficient operation and maintenance. These elements, each designed for a specific function, ensure that the equipment performs as expected under various conditions. Identifying the key components helps operators troubleshoot issues and maintain the machine’s efficiency over time.

Engine and Transmission are at the core of the equipment’s performance. The engine provides the necessary power, while the transmission ensures that this power is effectively distributed to the wheels or other operational systems. Regular monitoring and maintenance of these components are essential to avoid performance degradation.

Hydraulic and Structural Elements are equally important, as they facilitate lifting, tilting, and other vital movements. The hydraulic system, in particular, enables the manipulation of heavy loads, and the structural framework supports these movements by providing stability. These components must be regularly checked for leaks or wear to maintain smooth operation.

How to Use the Visual Reference Effectively

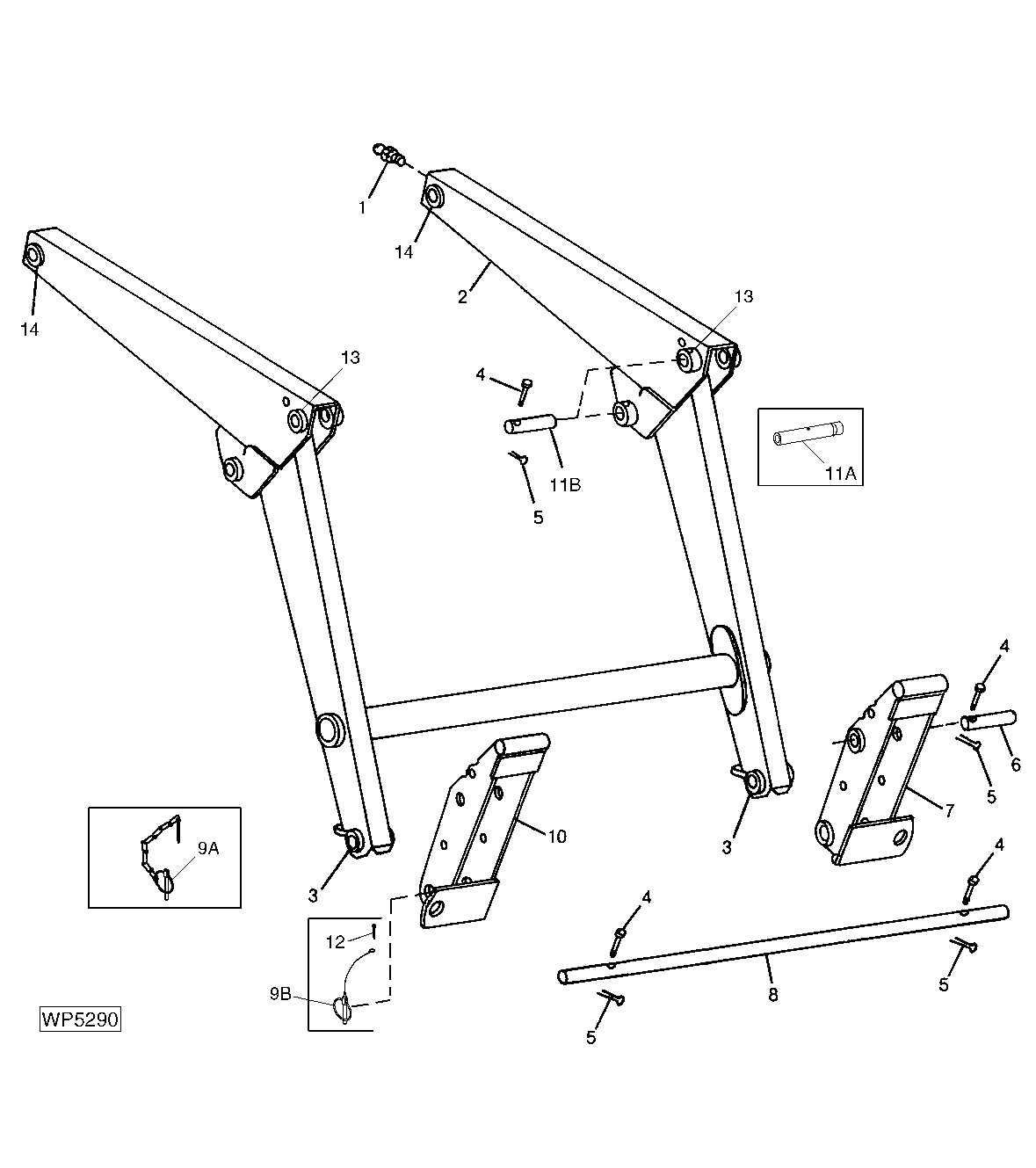

Utilizing a detailed visual reference can significantly improve the process of identifying and replacing equipment components. These resources allow operators and technicians to view the layout of the various elements, making it easier to locate parts that require attention. Understanding how to interpret these resources ensures that maintenance tasks are completed efficiently and accurately.

To make the most of a visual reference, it is important to familiarize yourself with the different sections and their corresponding labels. This understanding will help you navigate the resource quickly, enabling you to pinpoint any problematic areas without unnecessary delay. Additionally, cross-referencing the visual guide with the machine’s manual can provide further context on how each part functions within the overall system.

Regular use of this reference not only enhances diagnostic capabilities but also streamlines repair and replacement efforts. Being able to quickly locate a specific component and understand its connections with other systems reduces downtime and helps maintain the machine’s optimal performance.