Maintaining and repairing machinery requires a thorough understanding of its internal components. Knowing how each part functions and how to identify potential issues can save both time and money during upkeep. This guide will help you familiarize yourself with the key elements of your equipment and provide insights into locating and replacing the necessary pieces.

Efficient troubleshooting becomes much easier when you can visually connect the various components and understand their roles. By referring to a detailed layout, you can pinpoint exactly where a malfunction may have occurred, ensuring that the repair process is swift and accurate.

Whether you’re performing routine maintenance or handling an unexpected malfunction, knowing the structure of your device is critical. This overview will simplify the process of locating the right replacements and offer a clear view of what’s necessary for optimal performance.

Understanding the Equipment Components

Each machine consists of various essential elements that work together to ensure smooth operation. Recognizing these components and their specific functions allows for better maintenance and quicker identification of issues. Familiarity with these key elements will make it easier to diagnose and resolve any problems that may arise during use.

By studying the individual pieces, you can gain a clear understanding of how the machine operates and where common wear might occur. This knowledge helps in making informed decisions when it comes time to replace or repair parts, ensuring that you maintain optimal performance.

In addition, having a clear grasp of the machinery’s internal structure allows you to prevent unnecessary damage. Knowing what each component does also simplifies the process of assembling or disassembling the machine for any necessary adjustments.

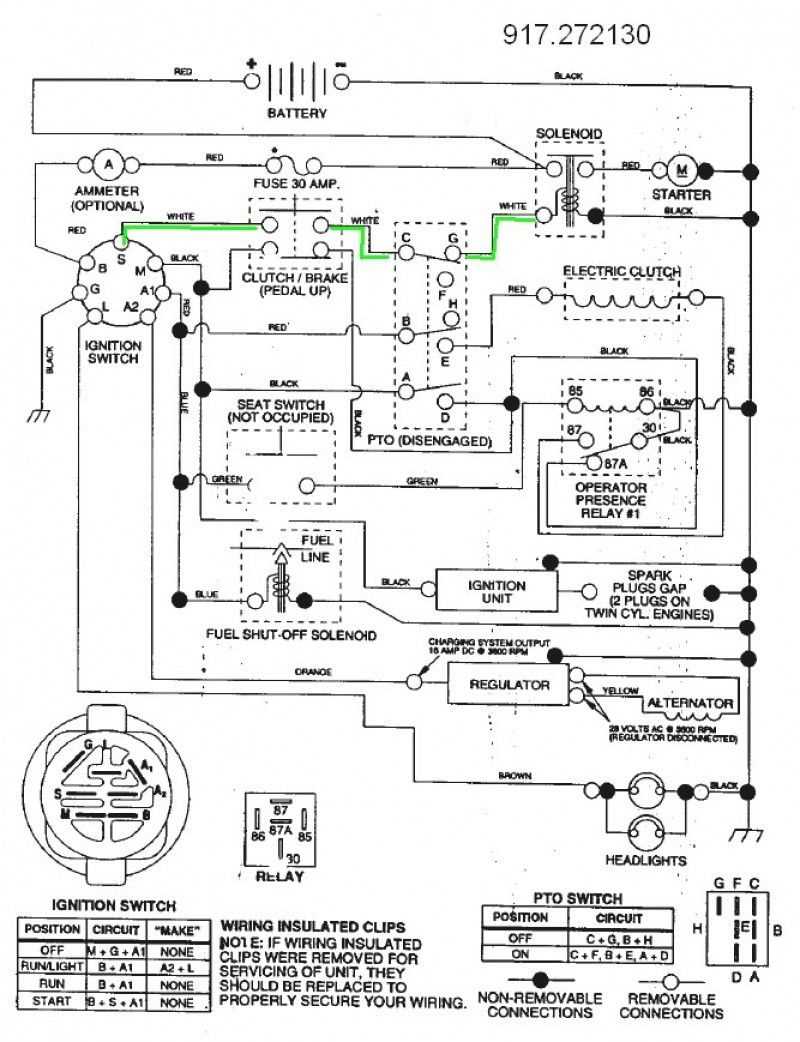

How to Read the Parts Diagram

To effectively understand the layout of your equipment, it’s essential to familiarize yourself with how to interpret its visual representation. These illustrations are designed to provide a clear view of the machine’s components, their positioning, and how they interconnect. By learning to read these visuals, you can quickly identify the individual elements and understand their roles within the overall structure.

The key to reading these diagrams lies in recognizing the symbols and labels associated with each part. These notations often include references to part numbers, descriptions, and their placement within the system. With this information, you’ll be able to pinpoint specific sections and determine whether any elements require attention or replacement.

Once you have identified the relevant parts and their functions, the next step is using this knowledge to troubleshoot issues or carry out maintenance tasks efficiently. A well-understood visual guide can streamline repairs and ensure that replacements are made accurately and without unnecessary confusion.

Identifying Common Replacement Parts

Understanding which components commonly need replacement can greatly enhance the efficiency of maintenance. Over time, certain elements of the equipment tend to wear out or become damaged more frequently than others. Knowing these common replacements allows you to prepare in advance and ensure smooth operations without unnecessary delays.

Frequently Replaced Components

Among the most commonly replaced pieces are the motor, belts, and gears. These parts are subject to frequent stress and, over time, may need to be swapped out to maintain the performance of the machine. Regular inspection can help detect wear early, preventing more serious breakdowns.

Tips for Identifying Wear

Pay attention to signs such as unusual noises, poor performance, or visible damage to certain parts. Often, these can indicate that specific elements are nearing the end of their lifespan. Consulting a visual guide can help you pinpoint which components require immediate attention and are most likely to need replacing.