When maintaining or repairing small engines, having a clear and detailed layout of their components is essential. Knowing where each part fits within the system can significantly ease the process of troubleshooting and replacing faulty parts. A well-organized illustration helps you visualize how the engine is assembled and how the individual pieces interact with one another.

Proper identification of each component ensures a smoother repair experience and minimizes the risk of errors during assembly. Whether you’re a professional mechanic or a DIY enthusiast, a thorough understanding of the engine’s structure is key to efficient maintenance.

By studying the layout carefully, you can save both time and money, avoiding unnecessary repairs and replacements. With the right guide, even complex mechanical systems become more accessible, enabling anyone to address issues with confidence.

Tecumseh LV195EA Engine Parts Overview

Understanding the key components of an engine is vital for both maintenance and repair. Each part plays a critical role in ensuring smooth operation, and knowing how they work together helps in diagnosing issues. From the fuel system to the ignition components, each element contributes to the engine’s efficiency and longevity.

The engine consists of several key systems, including the carburetor, spark plug, air filter, and fuel lines. These elements work in harmony to provide the power and performance needed for everyday tasks. A clear understanding of how each piece fits into the larger assembly can help in replacing or servicing components when needed.

With the right knowledge, identifying worn or damaged parts becomes simpler, leading to faster repairs. This overview of the engine’s key parts is designed to guide you through the most important components, ensuring you have the information needed to maintain or restore proper function.

Understanding the Components of Tecumseh LV195EA

Familiarizing yourself with the individual elements of an engine is crucial for effective maintenance and repair. Each component plays a significant role in the overall function, ensuring that the system operates smoothly and efficiently. Whether it’s the air intake system, the ignition, or the fuel delivery components, understanding their purpose is essential to addressing issues when they arise.

Key Systems and Their Functions

Engines rely on multiple interconnected systems to operate. The ignition system, for example, is responsible for initiating combustion, while the carburetor regulates the fuel-air mixture. The air filter ensures that only clean air enters the engine, preventing contaminants from causing damage. Recognizing how these systems interact is important for troubleshooting any performance issues.

Identifying Components for Maintenance

Knowing the layout of the engine helps in locating and identifying specific parts when performing maintenance. Regular checks on components such as the spark plug, fuel lines, and filters can prevent unnecessary breakdowns. Proper identification ensures timely replacement and helps maintain optimal performance.

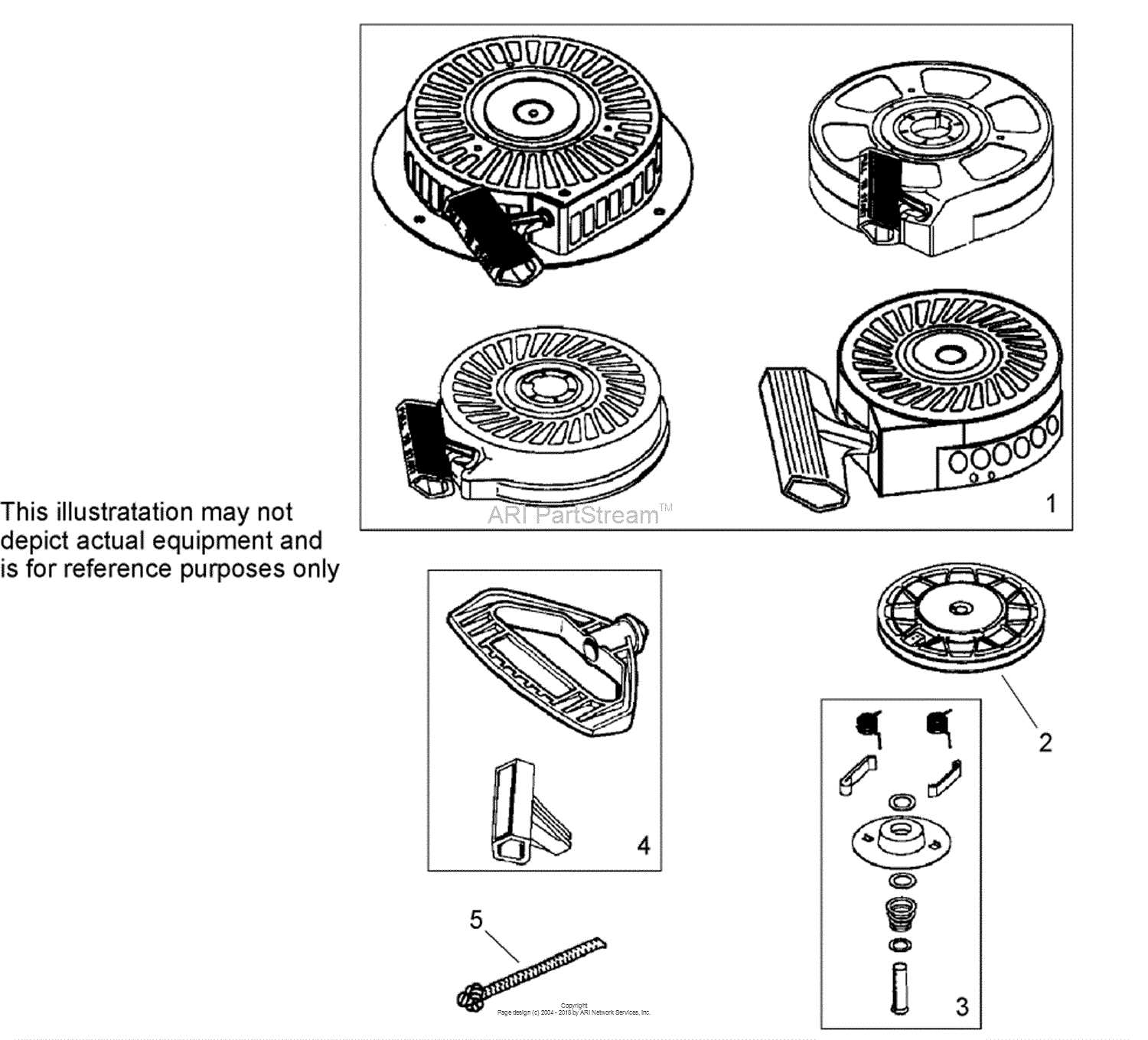

How to Use the Parts Diagram for Repairs

Utilizing a visual guide of engine components can greatly simplify the repair process. A well-organized reference helps you quickly identify where each part fits, making it easier to locate the faulty component. Whether you’re replacing a damaged piece or performing routine maintenance, having a clear layout at your disposal saves both time and effort.

Step-by-step guidance is key when following a schematic, allowing you to work through the engine systematically. Start by identifying the area that needs attention and cross-reference it with the layout. This approach ensures you don’t miss any crucial steps, preventing unnecessary disassembly or errors during reassembly.

Additionally, accurate labeling of each part on the guide ensures you know exactly which component you are handling, making replacements and repairs straightforward. By following the layout, you can be confident that each part is correctly installed, ensuring the engine functions properly after repairs are completed.