Machines that rely on internal combustion to generate power consist of various interconnected components. These elements work together in harmony to ensure efficient operation and long-term durability. A thorough understanding of how each component functions and interacts with others is crucial for maintaining the machinery’s peak performance and troubleshooting potential issues.

Key Components and Their Functions

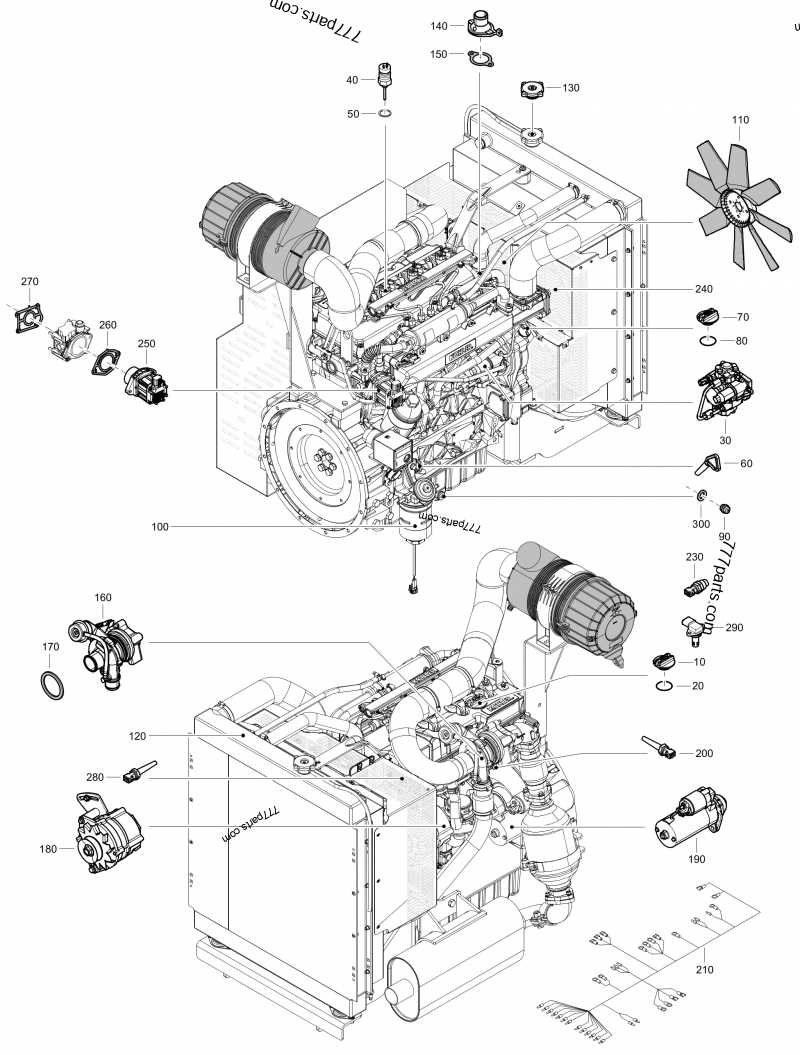

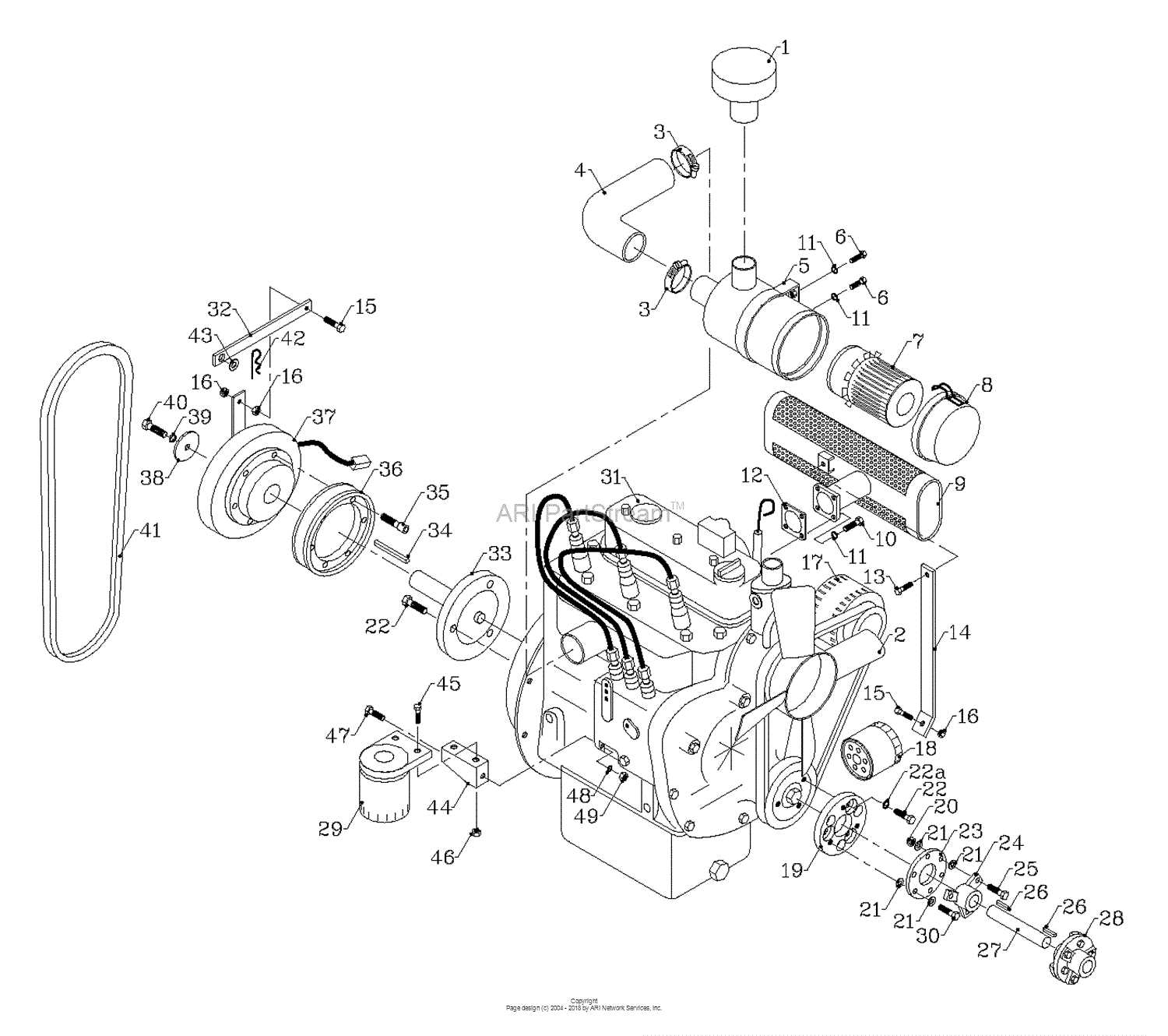

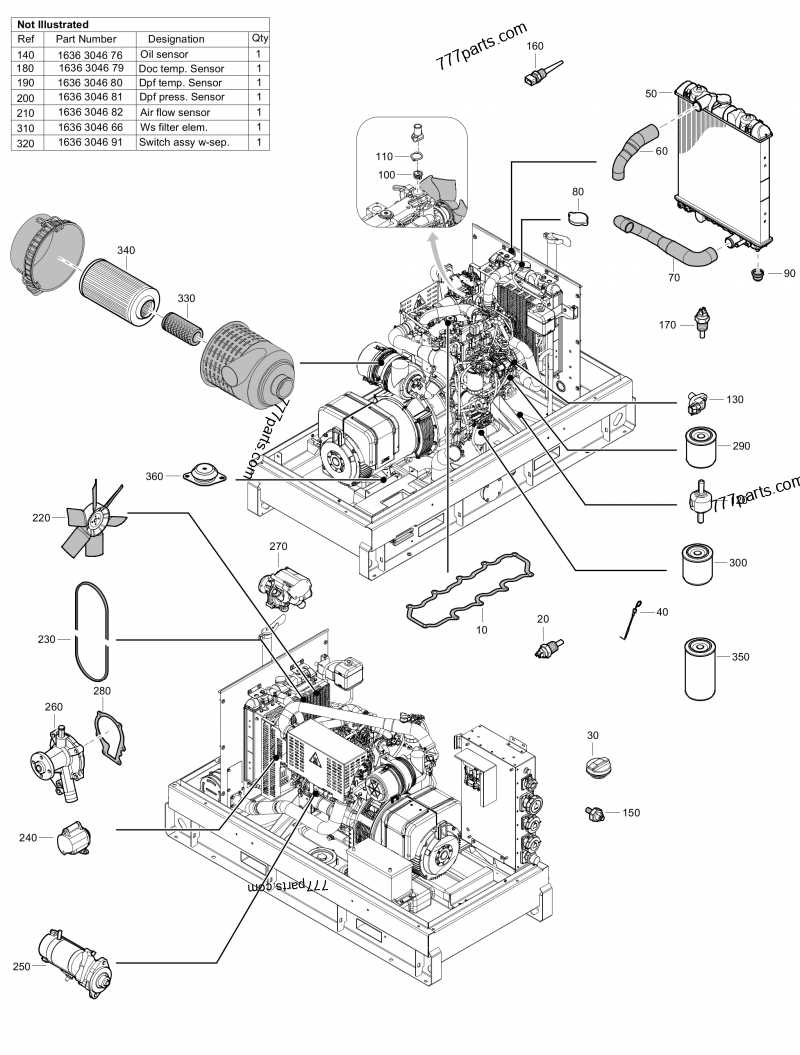

The heart of any combustion-powered system is a series of key components, each with a distinct role. These include elements responsible for intake, compression, combustion, and exhaust. Each function is vital to the overall process of energy generation and movement.

- Intake Valves: Control the flow of air or fuel mixture into the system.

- Pistons: Convert pressure into mechanical force that powers the machine.

- Crankshaft: Transforms the linear motion of the pistons into rotational power.

- Exhaust System: Expels gases produced during combustion.

How These Elements Interact

The proper functioning of each component relies on the effective communication between all elements. For example, the intake valves open at the right time to allow the mixture of fuel and air to enter, which is then compressed by the pistons. Once combustion occurs, the force generated pushes the pistons to turn the crankshaft, and exhaust gases are expelled through the exhaust system. Any disruption in the timing or condition of these components can lead to decreased performance or complete failure.

Preventing Issues Through Regular Maintenance

Consistent upkeep and monitoring are essential for avoiding mechanical problems. Regular checks help ensure that all parts remain in optimal condition, minimizing the risk of damage and improving the overall lifespan of the system. Replacing worn-out or faulty components before they affect the whole mechanism is an effective strategy for maintaining smooth operation.

Understanding Key Components and Their Interactions

In complex machinery, each element plays a significant role in ensuring the overall system functions efficiently. Understanding how these components work together and their individual contributions is crucial for diagnosing issues and maintaining peak performance. Each part has its own responsibility, from controlling the intake of fuel to expelling exhaust gases, and they must work in perfect synchronization to achieve optimal results.

How Components Interact with Each Other

The system’s efficiency depends on the seamless interaction between its elements. For instance, the intake valves manage the flow of air or fuel mixture, which is then compressed and ignited. This generates power, which is transferred to the mechanical components responsible for movement. The exhaust system then removes the byproducts of combustion, ensuring the cycle continues smoothly. Any malfunction in one of these elements can disrupt the whole operation, affecting performance and longevity.

Common Issues and Troubleshooting

Over time, wear and tear can lead to performance issues. One of the most common problems involves improper fuel flow, which can cause inefficient combustion or even complete failure. Another frequent issue is a failure in the exhaust system, leading to excessive heat buildup or harmful emissions. Regular inspections help identify these problems early, preventing costly repairs and improving the system’s reliability.

By understanding the role of each component and how they work together, operators can identify issues more effectively. Using detailed schematics or visual representations, it’s easier to locate faulty elements and resolve them before they affect overall performance. Regular maintenance ensures that all components continue functioning optimally, maximizing efficiency and extending the lifespan of the machinery.