When it comes to maintaining an efficient water circulation system, understanding its key components is essential. Identifying each element’s role and how they interact can help prevent malfunctions and ensure optimal performance. Whether you are performing routine maintenance or dealing with unexpected issues, being familiar with the internal structure of the system is crucial.

Efficient operation relies on knowing how each part contributes to the overall function. Small errors in setup or repair can lead to larger complications, so it is important to grasp the basic layout and function of each element involved. Recognizing the parts and their connections will allow you to troubleshoot effectively and manage repairs with confidence.

In this guide, we will break down the components of the system, explain their interactions, and provide useful tips for maintaining a smooth-running setup. Whether you’re a novice or an experienced individual, this overview will help ensure that you have the knowledge needed to keep everything in check.

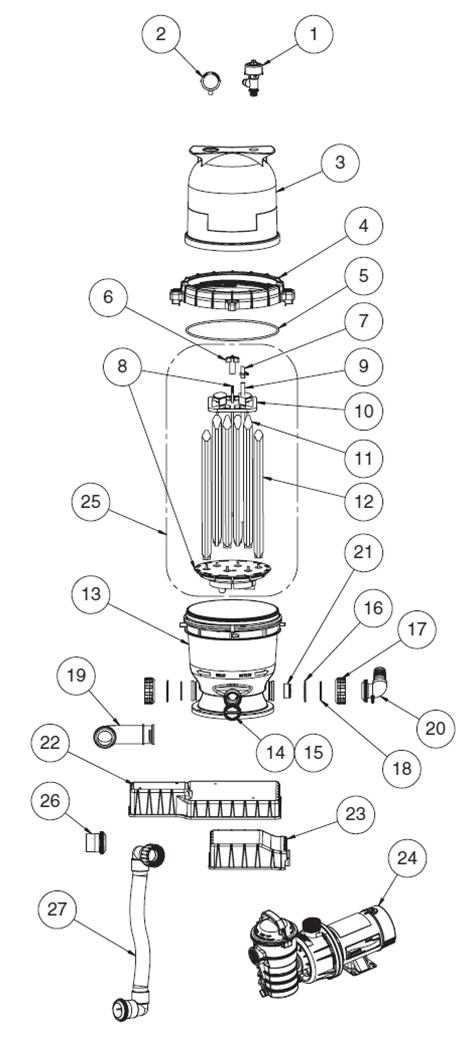

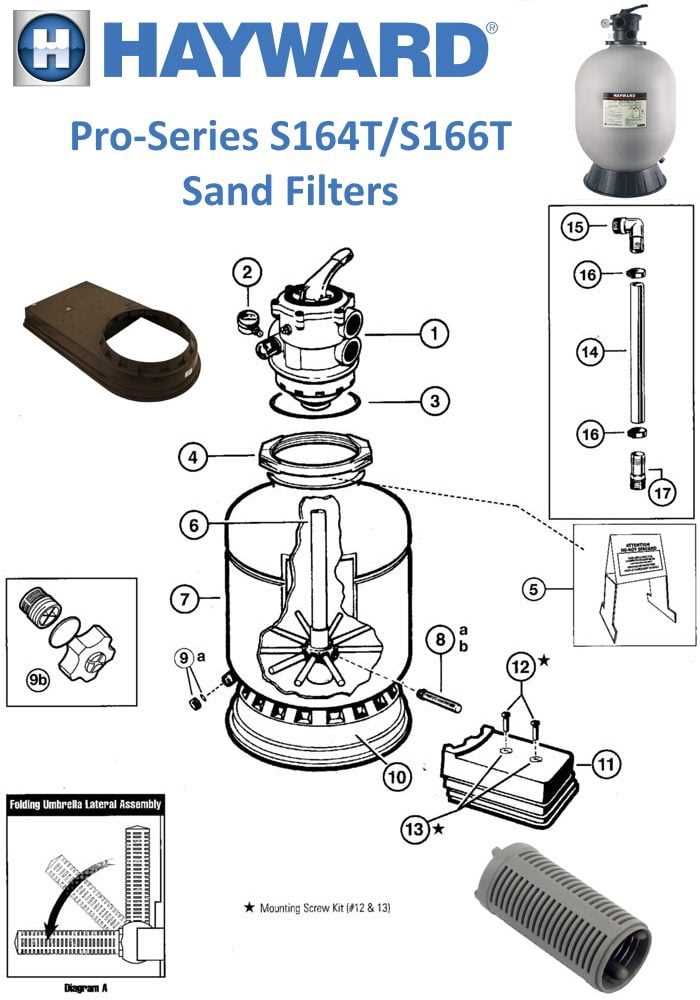

Understanding DE System Components

Each water circulation system consists of multiple essential elements that work together to maintain proper functionality. Recognizing these components and their respective roles ensures that the entire system operates efficiently, providing clean and clear water. From the intake to the outlet, every piece contributes to the overall process of managing water flow and quality.

The core components typically include mechanisms for water filtration, regulation of flow, and distribution. These work in tandem to remove debris, regulate pressure, and ensure the system can handle varying water volumes. By understanding the relationship between each part, it becomes easier to identify and resolve any issues that may arise.

Having a comprehensive knowledge of the structure allows you to handle maintenance tasks with confidence. Familiarity with the parts that require regular attention, such as those responsible for sealing and flow control, helps prevent costly repairs and extends the life of the system.

Common Issues and Troubleshooting Tips

Water circulation systems, like any complex machinery, can encounter a variety of issues that hinder their performance. Regular maintenance and a good understanding of how each element functions can help quickly identify problems before they escalate. Knowing the common faults and how to address them will keep your system running smoothly.

Low Water Flow

One of the most common issues is insufficient water flow. This can be caused by blockages, damaged seals, or problems with the pressure regulating components. If the water volume is noticeably lower than normal, check for obstructions in the system, and ensure all components are properly sealed. A simple cleaning of the intake or outflow area can often resolve this issue.

Unusual Noises

Strange sounds such as whining, rattling, or hissing can indicate an issue with the internal mechanisms. These noises often point to air being trapped within the system or a malfunction in the pressure regulation. If you hear unusual sounds, inspect the connections and valves for any signs of leaks, and ensure that the pressure settings are correct.

How to Replace Components in a DE System

Replacing malfunctioning or worn-out components is an essential part of maintaining the efficiency of any water circulation system. Properly swapping out these elements ensures that the system continues to operate at its best and avoids costly repairs down the line. Understanding the correct steps for replacement is key to a smooth process and long-lasting performance.

Step-by-Step Replacement Process

Follow these basic steps to replace damaged or outdated components in your system:

- Turn Off the System: Before beginning any replacement, ensure the system is turned off and disconnected from the power supply.

- Release Pressure: Open the release valve to let any built-up pressure out and prevent accidents during the replacement.

- Remove the Faulty Component: Carefully detach the malfunctioning part by loosening the screws or bolts that hold it in place. Take note of the orientation to avoid mistakes when installing the new part.

- Install the New Component: Place the new part in the correct position and secure it using the appropriate fasteners.

- Test the System: After installation, restore power and test the system to ensure everything is working properly.

Additional Tips

When replacing any part, it’s important to follow the manufacturer’s guidelines and choose compatible replacements. Here are a few tips for a successful replacement:

- Always have the right tools and equipment for the job to avoid damaging other components.

- Keep a record of the replacement date to ensure you stay on top of future maintenance.

- If unsure, consult a professional to avoid further damage to the system.