Proper knowledge of equipment components and their assembly is essential for anyone involved in maintenance or repairs. Being familiar with the individual parts and how they fit together ensures smooth operation and longevity of the device. Whether you’re a seasoned technician or a beginner, understanding the intricacies of machinery can prevent common mistakes and extend the life of your tools.

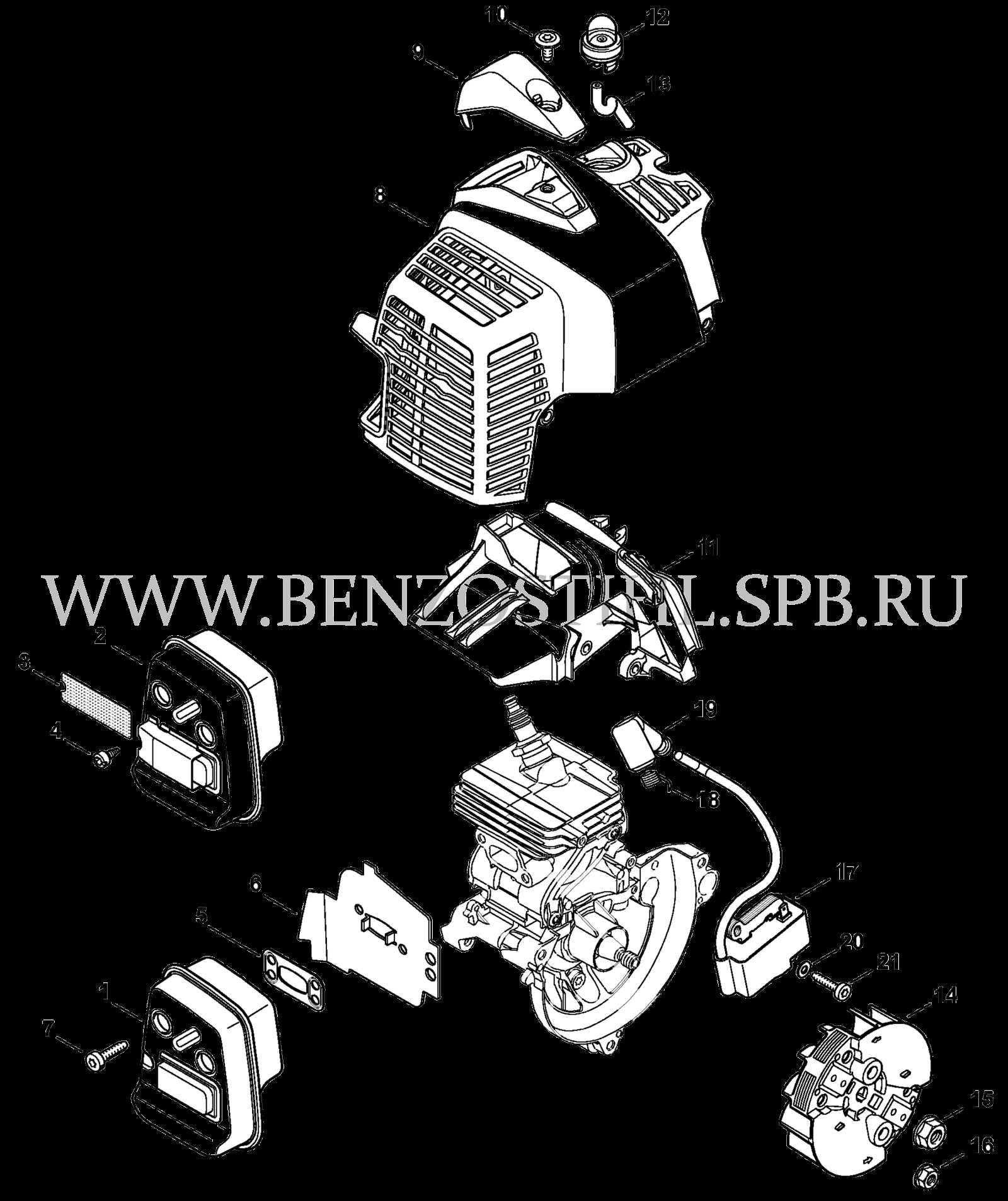

Efficient troubleshooting and repair require a clear understanding of how all the elements work together. With a visual guide to the internal structure, identifying malfunctioning parts becomes much easier. This approach saves time and minimizes unnecessary damage to other components.

Having access to detailed breakdowns simplifies the repair process and offers valuable insight into reassembly. This kind of knowledge helps in pinpointing problems quickly and making informed decisions when replacing or fixing parts.

Understanding the Equipment Components

To ensure the proper functioning of any machine, it is crucial to understand the various elements that make up its structure. Every component serves a specific purpose, contributing to the overall performance and reliability of the tool. By recognizing how each piece interacts with the others, users can better maintain and repair the device when necessary.

In most equipment, the internal system includes critical elements such as the engine, air intake, exhaust, and ignition components. These parts work in unison to deliver power, control airflow, and maintain the machine’s efficiency. A solid grasp of these components allows for more precise diagnostics when issues arise.

Knowing the configuration of these elements is particularly useful when it comes to maintenance tasks, whether it’s replacing worn-out parts or addressing potential failures. Understanding the role of each component helps technicians and users alike to act quickly and accurately, ensuring the equipment operates smoothly for years to come.

How to Use the Parts Diagram Effectively

Having a detailed visual representation of a device’s components is an invaluable tool for both repair and assembly. It helps identify each element’s location and function, making maintenance tasks more efficient. By carefully following the illustration, users can locate specific parts quickly and avoid mistakes during repairs.

To use the visual guide effectively, start by familiarizing yourself with the general layout and grouping of components. Understand how each part interacts with the others and which pieces need attention. Pay special attention to labels and numbers that correspond to parts, as these can help you identify replacements or components to inspect more closely.

Additionally, take note of any suggested procedures for disassembly or reassembly. These instructions often highlight the correct order of steps, which can prevent unnecessary damage to delicate parts. When used correctly, the visual breakdown allows for smooth and accurate repairs, saving both time and effort.

Step-by-Step Guide for Assembly and Repair

When it comes to assembling or repairing machinery, following a clear and methodical approach is key to success. Each step should be executed with care, ensuring that all components are correctly positioned and secured. A structured guide provides valuable assistance in preventing errors that could lead to performance issues or damage.

The first step is to gather all necessary tools and components. Ensure you have a clean workspace, as this will help in managing small elements and avoiding misplaced parts. Carefully follow the sequence outlined in the guide, starting with larger components and gradually moving to the more delicate elements. This process ensures that everything fits into place without unnecessary pressure or force.

As you progress, take time to check the alignment and integrity of each part before proceeding. If any discrepancies arise, consult the visual guide to verify the correct assembly order. Once all components are securely in place, conduct a final inspection to ensure everything is functioning as expected. Properly following each step will result in a well-assembled and fully operational machine.